Curable silicone composition, method for obtaining thermally conductive cured product and adhesive tape and adhesive film having the cured product

A silicone composition and curable technology, applied in chemical instruments and methods, heat exchange materials, film/sheet adhesives, etc., can solve problems such as inability to adapt to high thermal conductivity and insufficient thermal conductivity, and achieve High reliability, improved manufacturing efficiency, and high thermal conductivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] Hereinafter, although an Example and a comparative example are shown and this invention is demonstrated in more detail, this invention is not limited to a following example.

[0106] Each component used in the following Examples and Comparative Examples is as follows.

[0107] (a) Organopolysiloxane having an alkenyl group

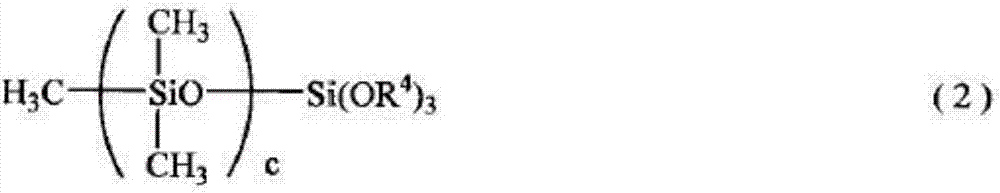

[0108] (a-1) having a dynamic viscosity at 25°C represented by the following formula (a) of 600 mm 2 An organopolysiloxane containing vinyl (Vi) groups at both ends of / s. The number of vinyl groups was 0.015 per 100 g of the organopolysiloxane.

[0109] [chemical 8]

[0110]

[0111] (a-2) The kinematic viscosity at 25°C represented by the formula (a) is 30,000mm 2 An organopolysiloxane containing vinyl (Vi) groups at both ends of / s. The number of vinyl groups was 0.0036 per 100 g of the organopolysiloxane.

[0112] (b) Thermally conductive filler

[0113] Component (b-1) Alumina powder having an average particle diameter of 1 μm, contai...

Embodiment 1~ Embodiment 6 and comparative example 1~ comparative example 5

[0132] The above-mentioned components were prepared in parts by mass described in Table 1 and Table 2, and mixed uniformly to prepare a silicone composition. Mix using a planetary mixer. An appropriate amount of toluene was added to the obtained silicone composition, and it was applied on two PET films surface-treated with a fluorine-based release agent (X-70-201 manufactured by Shin-Etsu Chemical Co., Ltd.). A notched wheel coater was used for the coating. After volatilizing toluene at 80° C., curing was performed at 120° C. for 5 minutes to obtain an adhesive tape having a thermally conductive cured material layer with a thickness of 30 μm and an adhesive tape with a thermally conductive cured material layer with a thickness of 50 μm.

[0133] About each silicone composition, adhesive force and thermal conductivity were measured according to the following method. The results are shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com