Light-emitting film based on chlorine-doped graphene quantum dots and preparation method thereof

A technology of graphene quantum dots and light-emitting films, applied in light-emitting materials, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve problems such as poor film stability, and achieve good thermal stability, The effect of uniform size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Weigh 1.0 g of β-cyclodextrin, 1.0 ml of hydrochloric acid, and 25 ml of deionized water, and disperse them ultrasonically for 15 minutes to make them evenly mixed, and place them in a flanged hydrothermal kettle, and keep them warm at 140°C for 6 hours. Chlorine-doped graphene quantum dots (Cl-GQDs solution) can be obtained by filtering through a 0.22-micron filter membrane and dialysis with a 1000Da semi-permeable membrane for three days.

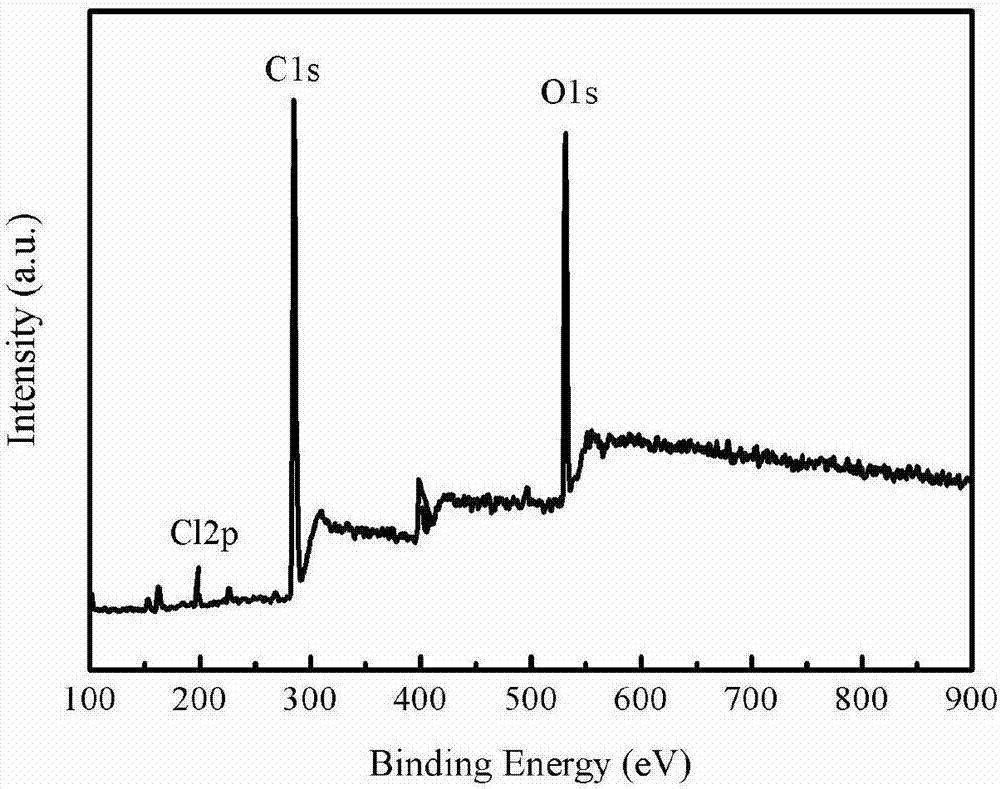

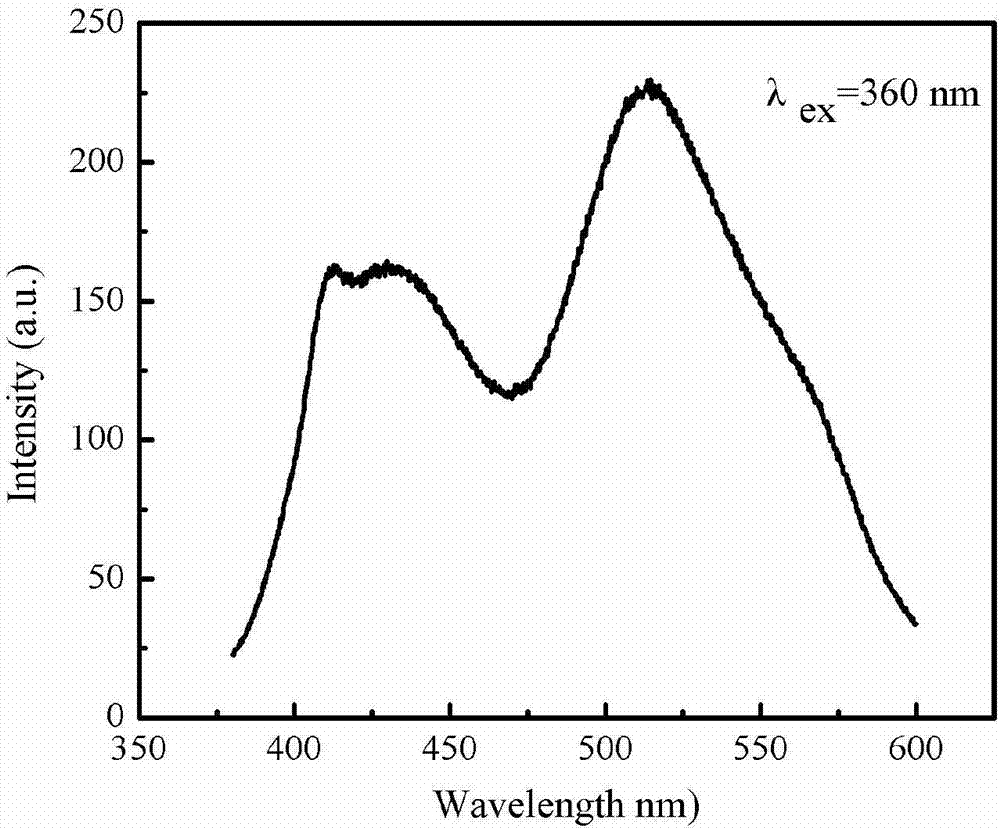

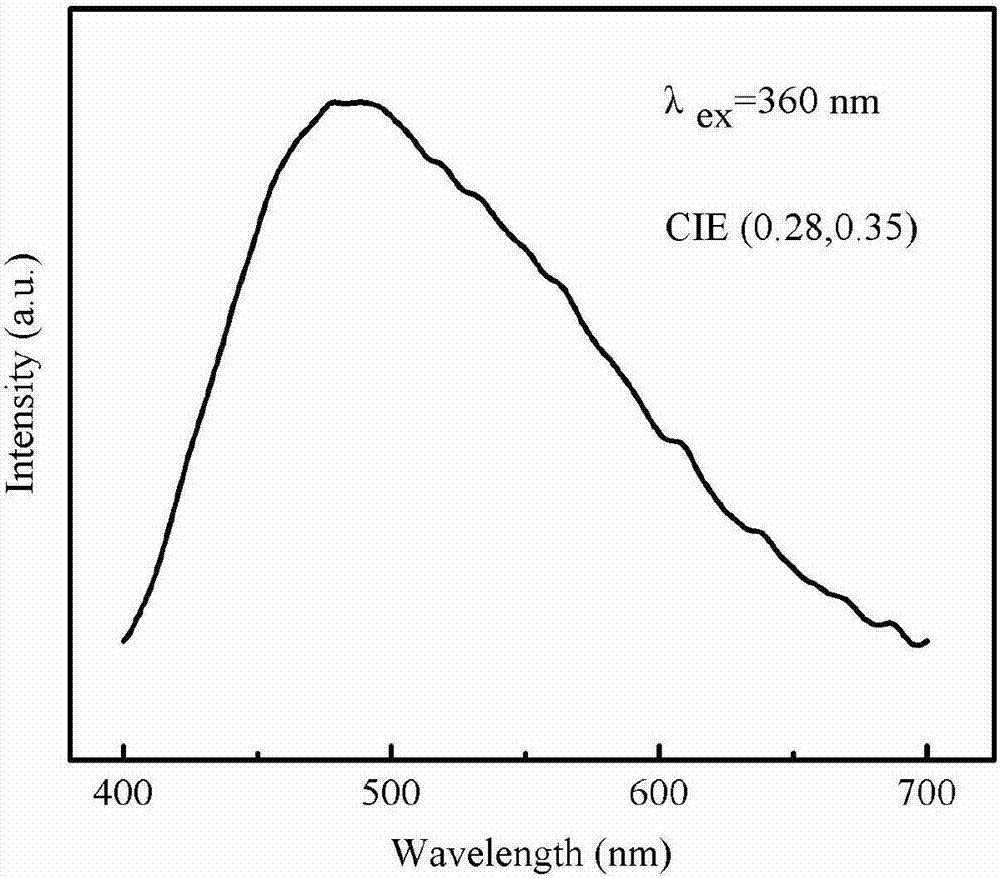

[0047] figure 1 It is the XPS full spectrum based on chlorine-doped graphene quantum dots provided by the embodiment of the present invention. figure 2 It is the PL spectrum based on chlorine-doped graphene quantum dots under 360 nm excitation provided by the embodiment of the present invention.

[0048] Weigh 11 grams of silicone resin, and stir vigorously to mix the silicone resin evenly; measure 1 ml of the prepared Cl-GQDs solution, drop it into the silicone resin, stir it manually for 10 minutes, and vacuum defoam 5 minutes...

Embodiment 2

[0051] Weigh 1.0 g of β-cyclodextrin, 1.5 ml of hydrochloric acid, and 25 ml of deionized water, and disperse them ultrasonically for 15 min to make them evenly mixed. Place them in a flanged hydrothermal kettle and keep them warm at 160°C for 6 hours. Chlorine-doped graphene quantum dots can be obtained by filtering with a 0.22-micron filter membrane and dialysis with a 1000 Da semi-permeable membrane for three days. Weigh 11 grams of silicone resin, and stir vigorously to make the silicone resin mix evenly; measure 1.5 ml of the prepared Cl-GQDs solution, drop it into the silicone resin, stir it manually for 10 minutes, and vacuum defoam 5 minutes; then measure 3 ml of the mixed glue solution and place it in a polytetrafluoroethylene mold, pre-bake it in a blast oven at 50 °C for 3 hours, and finally dry it at 80 °C for 24 hours to obtain solid Cl-GQDs / Silicone film.

Embodiment 3

[0053] Weigh 1.0 g of β-cyclodextrin, 2.0 ml of hydrochloric acid, and 25 ml of deionized water, and disperse them ultrasonically for 15 minutes to make them evenly mixed, and place them in a flanged hydrothermal kettle, and keep them warm at 160°C for 8 hours. Chlorine-doped graphene quantum dots can be obtained by filtering with a 0.22-micron filter membrane and dialysis with a 1000 Da semi-permeable membrane for three days. Weigh 11 grams of silicone resin, and stir vigorously to make the silicone resin mix evenly; measure 2 ml of the prepared Cl-GQDs solution, drop it into the silicone resin, stir it manually for 10 minutes, and vacuum defoam 5 minutes; then measure 3 ml of the mixed glue solution and place it in a polytetrafluoroethylene mold, place it in a blast oven at 50 °C for 3 hours, and finally dry it at 80 °C for 24 hours to obtain solid Cl-GQDs / Silicone film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com