Preparation method of monobutyltin oxide

A technology of monobutyltin oxide and monobutyltin trichloride, which is applied in the field of preparation of monobutyltin oxide, and can solve problems affecting the purity and production efficiency of monobutyltin oxide products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

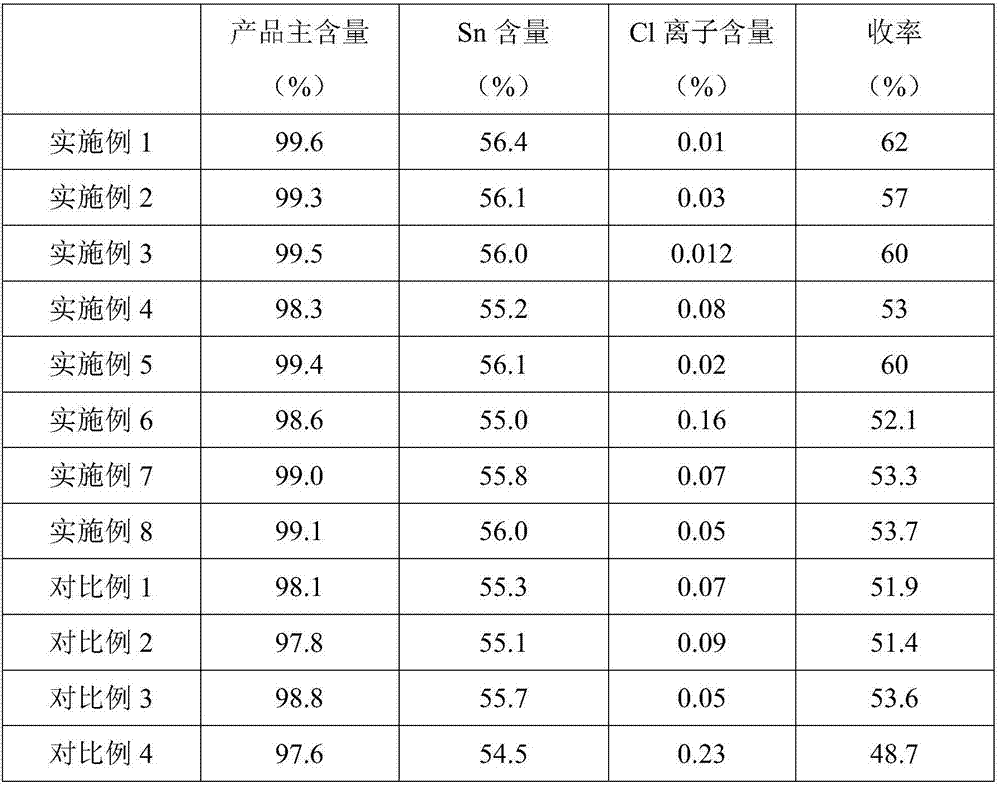

Examples

preparation example Construction

[0029] The invention provides a kind of preparation method of monobutyl tin oxide, comprises the following steps:

[0030] (1) Add tetrabutyltin into the reactor, stir evenly, slowly add tin tetrachloride dropwise, after the dropwise addition, stir for 30min, raise the temperature to 140°C, keep warm for 4-8h, and after the reaction is over, monobutyl trichloride is obtained. A mixed solution of tin chloride and dibutyl tin dichloride;

[0031] (2) The mixed solution of monobutyl tin trichloride and dibutyl tin dichloride is heated up to 95-100° C., and the boiling points of the two substances in the mixture are different, and monobutyl tin trichloride, dibutyl tin trichloride, Dibutyltin dichloride, collect monobutyltin trichloride;

[0032] (3) Add monobutyl tin trichloride, surfactant, organic solvent collected in step (2) to the reactor, after stirring evenly, slowly add sodium hydroxide solution dropwise, after dropwise, be warming up to 90 ℃, heat preservation reaction...

Embodiment 1

[0069] The preparation method of described monobutyl tin oxide comprises the following steps:

[0070] (1) Add tetrabutyltin into the reactor, stir evenly, slowly add tin tetrachloride dropwise, after the dropwise addition, stir for 30min, heat up to 140°C, keep warm for 6h, and the reaction is over to obtain monobutyltin trichloride A mixed solution of tin and dibutyltin dichloride;

[0071] (2) Warm up the mixed solution of monobutyltin trichloride and dibutyltin dichloride to 98°C, the boiling points of the two substances in the mixture are different, and the monobutyltin trichloride, dibutyltin trichloride and dibutyltin trichloride are successively distilled. Base tin dichloride, collect monobutyl tin trichloride;

[0072] (3) Add monobutyl tin trichloride, surfactant, organic solvent collected in step (2) to the reactor, after stirring evenly, slowly add sodium hydroxide solution dropwise, after dropwise, be warming up to 90 ℃, keep warm for 4 hours, cool down to room ...

Embodiment 2

[0084] The preparation method of described monobutyl tin oxide comprises the following steps:

[0085] (1) Add tetrabutyltin into the reactor, stir evenly, slowly add tin tetrachloride dropwise, after the dropwise addition, stir for 30min, heat up to 140°C, keep warm for 6h, and the reaction is over to obtain monobutyltin trichloride A mixed solution of tin and dibutyltin dichloride;

[0086] (2) Warm up the mixed solution of monobutyltin trichloride and dibutyltin dichloride to 98°C, the boiling points of the two substances in the mixture are different, and the monobutyltin trichloride, dibutyltin trichloride and dibutyltin trichloride are successively distilled. Base tin dichloride, collect monobutyl tin trichloride;

[0087] (3) Add monobutyl tin trichloride, surfactant, organic solvent collected in step (2) to the reactor, after stirring evenly, slowly add sodium hydroxide solution dropwise, after dropwise, be warming up to 90 ℃, keep warm for 4 hours, cool down to room ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com