Efficient and environment-friendly oxidation technological method for aluminum alloy

An oxidation process, aluminum alloy technology, applied in the direction of anodic oxidation, coating, electrolytic components, etc., can solve the problems of reduced dissolution rate of oxide film, low yield of production line, reduced film forming speed, etc., to avoid the problem of color difference, Realize the effect of intelligent control and improve the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

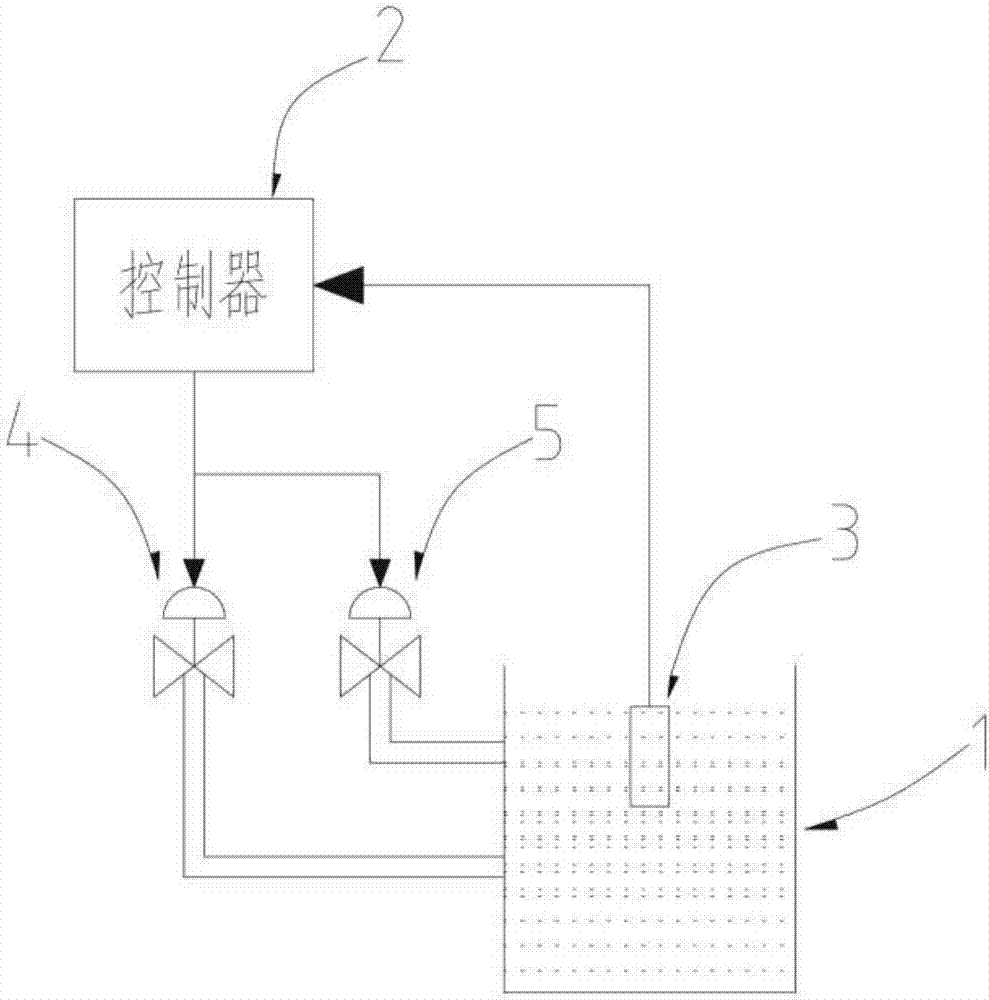

[0014] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0015] The high-efficiency and environment-friendly oxidation process method of aluminum alloy includes the steps of degreasing, alkali etching, water washing, oxidation, electrolytic coloring, water washing, and recovery of water washing. The process parameters of the anodizing bath solution are: sulfuric acid H 2 SO 4 165-200g / L, the concentration of aluminum AL ion is less than 20g / L, the concentration of iron Fe ion is less than 2g / L, the concentration of copper Cu ion is less than 0.02g / L, the concentration of chloride is less than 0.02%, the temperature is 15-20 degrees, the current density 1~2.5A / dm 2 , The electrolysis time is 20-50 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com