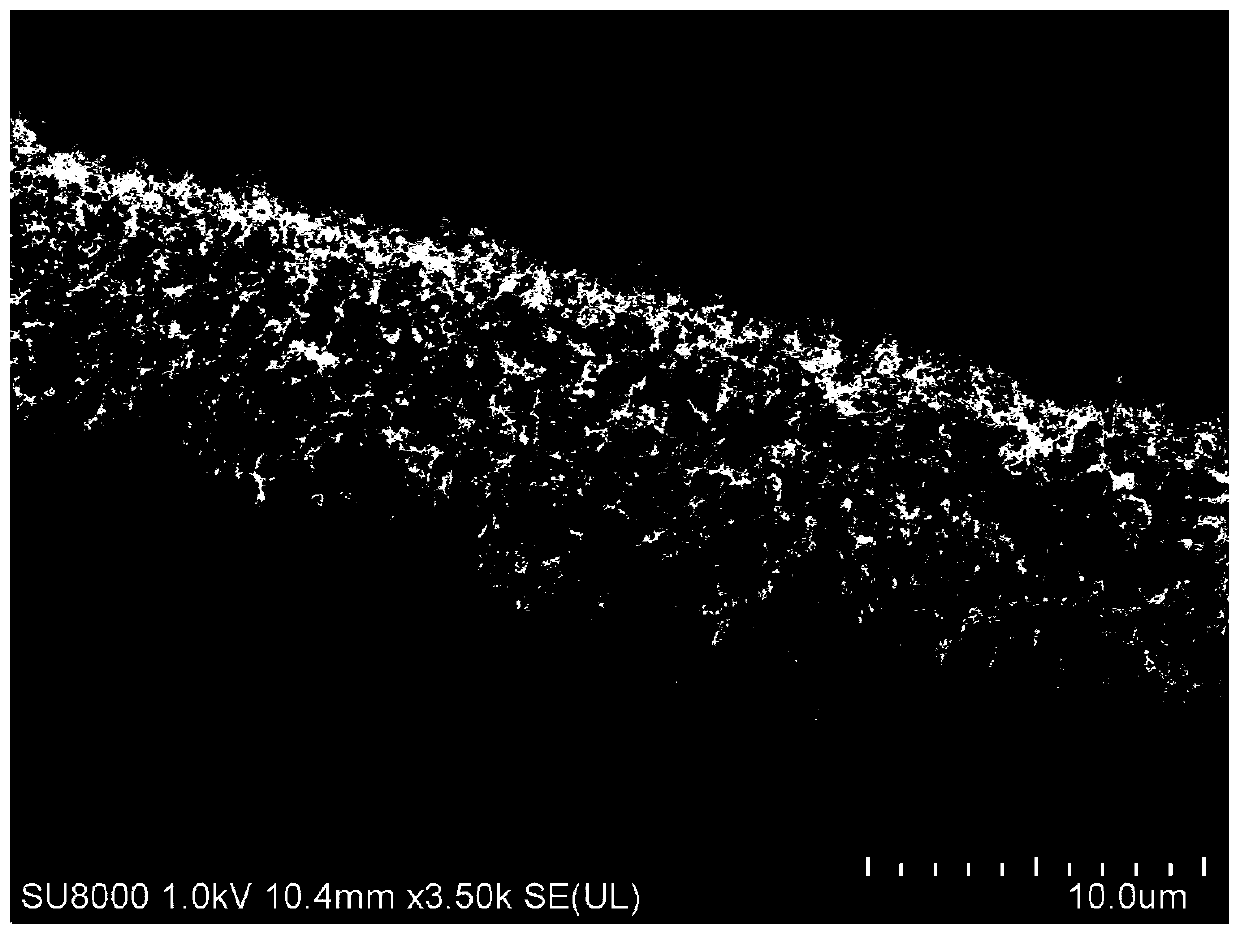

A surface modification method for carbon fiber to quickly attach double-phase layer carbon nanotubes

A carbon nanotube and surface modification technology, which is applied in the field of micro-nano materials to achieve the effects of simple implementation method, increased surface roughness, and better performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Mix carbon nanotubes with an appropriate amount of working fluid and press them into electrodes with a certain shape. Put two carbon nanotube electrodes opposite each other, leaving a gap of 1-2 mm in the middle. After sizing the carbon fiber monofilament, when the slurry is not completely dry Pass through the gap between the opposite carbon nanotube electrodes at a certain speed. The carbon fiber monofilament passing through the electrode gap can be single or multiple at a certain distance. The carbon fiber can never touch the carbon nanotube electrode in the above process; the carbon fiber single Wire and carbon nanotube electrodes are connected to high voltage to make the carbon fiber monofilament in the gap discharge the carbon nanotube electrodes on both sides, wherein the high voltage can be direct current or alternating current, the lower limit of voltage should be enough to generate spark discharge, and the upper limit of voltage should be above No damage to carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com