Method for installing pre-discharge lightening rod

An installation method and lightning rod technology, applied in the installation of cables, installation of lighting conductors, electrical components, etc., can solve the problems of small protection radius, low protection safety, poor equipment and personnel safety guarantee, etc., to achieve large protection radius and safety. High reliability and light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The installation method of pre-discharge lightning rod of the present invention comprises the following steps:

[0037] a. Assemble the parts of the pre-discharge lightning rod, and fix the pre-discharge lightning rod on the base as a whole by bolt fastening or welding.

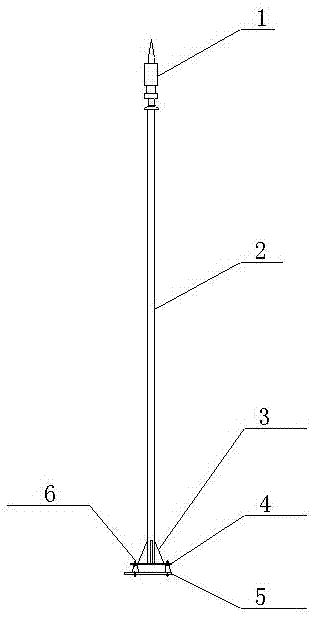

[0038] see now figure 1 , figure 1 It is a schematic diagram of the installation of the pre-discharge lightning rod according to the embodiment of the present invention. As shown in the figure, the pre-discharge lightning rod 1 is connected to the pillar 2, and the pillar 2 is fixedly connected to the installation base plate 4 through the stiffener 3. The resistance value between the base and the lightning rod is not greater than 5Ω.

[0039] b. When installing the pre-discharge lightning rod, the pre-discharge lightning rod and the down-conductor shall be welded with hot flux; the grounding resistance of the down-conductor shall not be greater than 10Ω.

[0040] c. A grounding resistance test box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com