Metal mixed powder and contact processing method for mobile phone antenna contacts

A technology of mixed powder and mobile phone antenna, applied in metal material coating process, coating, fusion spraying, etc., can solve the problems of high welding difficulty, large difference in melting point, small conduction resistance, etc., and achieve stable mobile phone signal transmission , to meet the effect of stable transmission and small on-resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

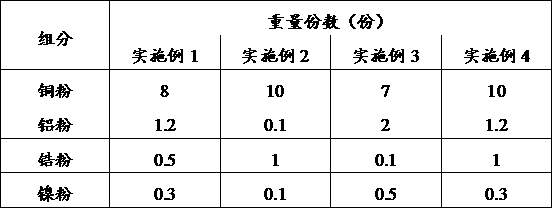

[0027] A metal mixed powder used for mobile phone antenna contacts, the parts by weight of the components contained in it are shown in Table 1.

[0028] Table 1

[0029]

[0030] The production method of the metal mixed powder used for mobile phone antenna contacts: (1) mix various metal powder components, and use a drum mixer to stir evenly; (2) dry at 100±2°C for 5 to 6 hours to obtain a metal powder Mix powder. Each component selects metal powder with a particle size of 20-50 microns.

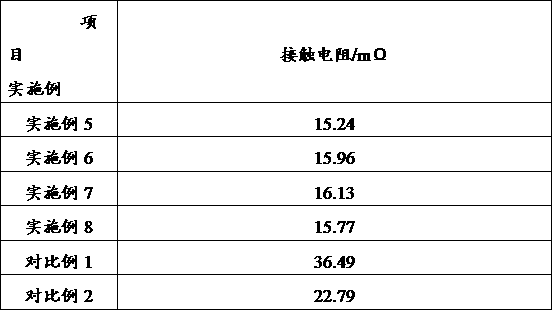

Embodiment 5

[0032] A method for processing a mobile phone antenna contact, comprising the following steps:

[0033] (1) Paste a protective film on the mobile phone case or fix the mobile phone case on a shielding fixture, and the protective film or shielding fixture will cover the area on the mobile phone case that has not been sprayed, exposing the contact pattern area that needs to be sprayed;

[0034] (2) thermally spray the metal mixed powder used for the antenna contact of the mobile phone onto the contact pattern area to form a contact coating; the metal mixed powder used in this example is the metal mixed powder prepared in Example 1;

[0035] (3) Remove the protective film or masking fixture.

[0036] The thermal spraying heating temperature is 1500°C, and the coating thickness is 0.3um.

Embodiment 6

[0038] A method for processing a mobile phone antenna contact, its processing steps and conditions are the same as in Example 5, the difference is that the metal mixed powder used for the mobile phone antenna contact described in this embodiment is the obtained embodiment 2 for the mobile phone antenna contact Dots of mixed metal powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com