Production technology for environment-friendly insulating gas and industrial production device

A technology of insulating gas and production process, which is applied in the preparation of acyl halide, dehydration of carboxylic acid amide, and preparation of organic compounds, etc. It can solve the problems of uneconomical industrial production, high cost, perfluoropentacarbonone and perfluorotetracarbonyl Complicated reaction conditions and other issues, to achieve the effect of non-toxic recovery, easy recovery, and low-cost replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

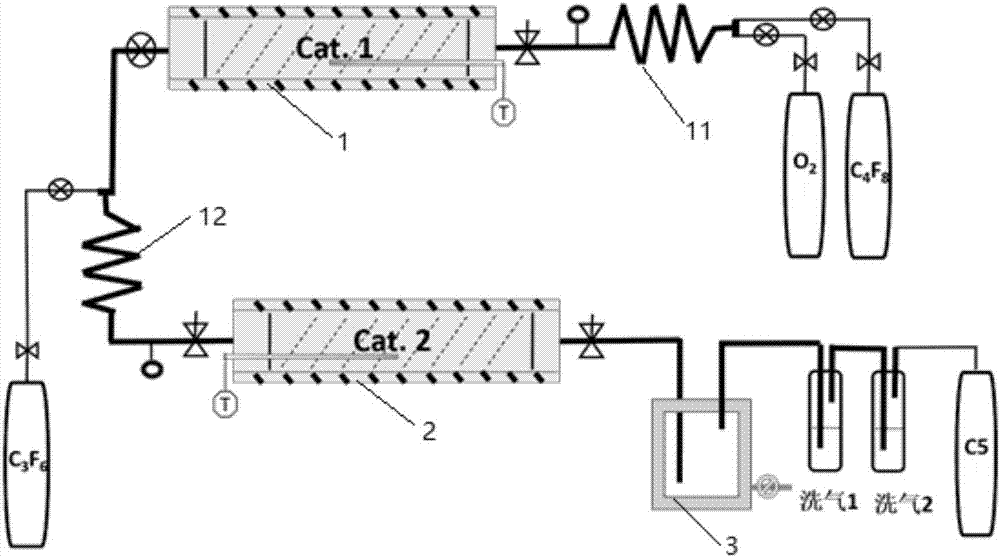

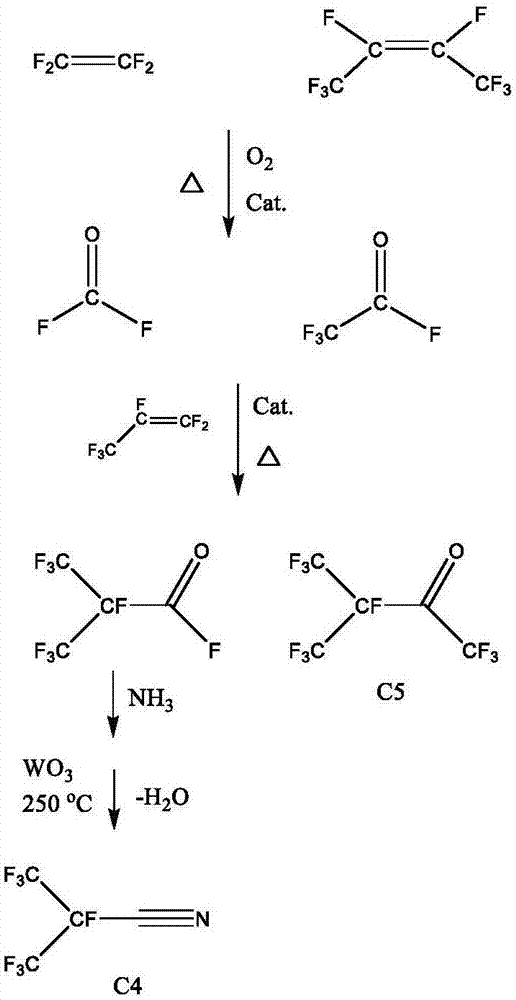

[0042] See figure 1 As shown, the first fixed-bed reactor 1 is 80cm long, 1 inch pipe diameter, and the reaction temperature is 250°C. 10% silver oxide supported on activated carbon is used as the catalyst. The catalyst filling ratio in the reactor is 50% (400mL). 2 (200mL / min) and perfluoro-2-butene (200mL / min) enter the first fixed-bed reactor 1 through the preheated mixing pipeline for reaction, and the reaction pressure is 2bar. The effluent gas from the first fixed bed reactor 1 is mixed with 1.2 equivalents of HFP (450 mL / min) and enters the second fixed bed reactor 2. The fixed bed reactor 2 is 80cm long, 1 inch diameter, reaction temperature 125°C, 10% CsF supported by activated carbon as the catalyst, the catalyst filling ratio in the second fixed bed reactor is 75% (400mL), and the reaction pressure is 1.5bar. The main product of the reaction is (CF 3 ) 2 CFCOCF 3 The total yield of the reaction was 91.1%. The effluent of the second fixed bed reactor 2 is passed into ...

Embodiment 2

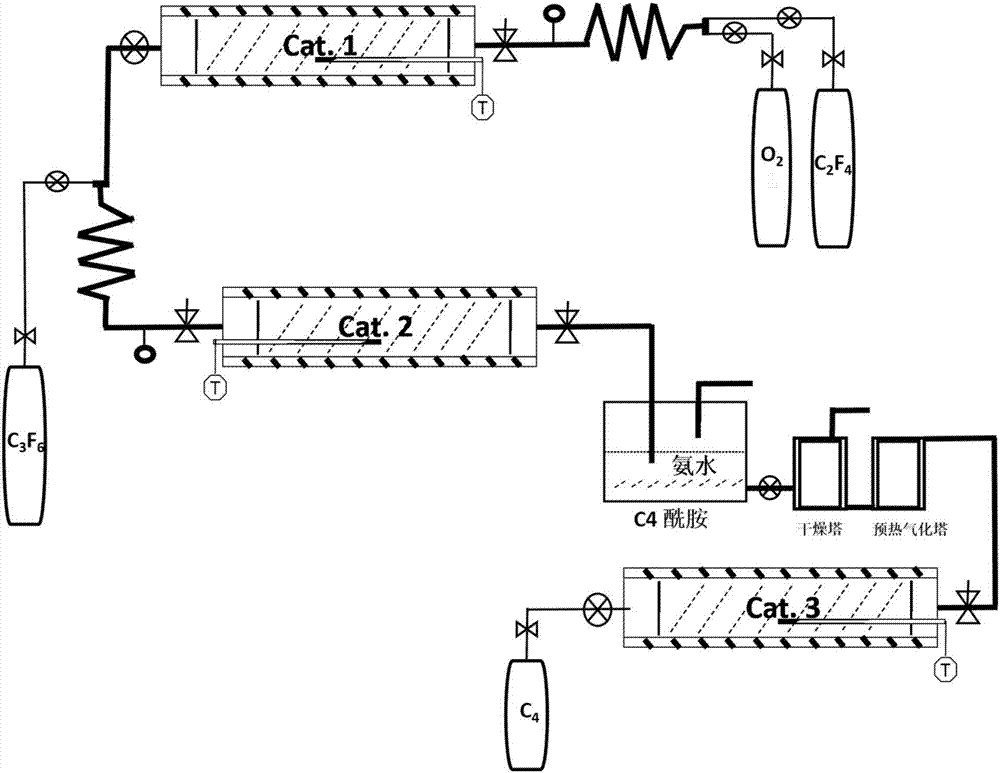

[0044] See figure 2 As shown, the first fixed bed reactor 1 is 80cm long, 1 inch diameter, and the reaction temperature is 250°C. 10% silver oxide supported on activated carbon is used as the catalyst. The catalyst filling ratio in the first fixed bed reactor is 50% (400mL). O 2 (100mL / min) and tetrafluoroethylene (100mL / min) enter the first fixed-bed reactor through the first preheating mixing pipeline to react, and the reaction pressure is 2bar. The effluent gas from the first fixed bed reactor 1 is mixed with 1.2 equivalent HFP (280 mL / min) and enters the second fixed bed reactor 2. The second fixed-bed reactor 2 is 80cm long, 1 inch pipe diameter, reaction temperature 125°C, activated carbon supported 10% CsF as catalyst, catalyst filling ratio in the reactor is 50% (250mL), reaction pressure is 1.2bar, reaction product Directly import concentrated ammonia water to obtain the precursor amide product aqueous solution, the reaction yield is 94.3%, the precursor amide product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com