Preparation method of composite paste for reactive dye printing

A reactive dye and printing technology, applied in dyeing, textile and papermaking, etc., can solve the problem of single paste performance, and achieve the effect of clear pattern outline, good shear thinning and strong affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

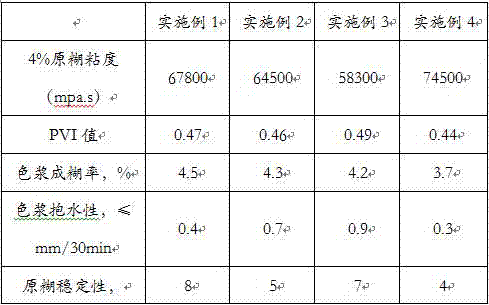

Examples

Embodiment 1

[0020] The composite paste of the present invention is as follows: respectively weigh 400kg of modified starch, 150kg of CMC (DS is 1.0, 1% aqueous solution viscosity 2000mpa.s), 100kg of modified guar gum and mix evenly, and put into 80% ethanol Disperse evenly in the solution, raise the temperature to 40°C, add 3.25kg nonylphenol polyoxyethylene ether, stir and react at constant temperature for 2 hours, centrifuge, dry, and pulverize to obtain the composite printing paste.

[0021] The preparation process of the modified tapioca starch used in the present invention is as follows: 400 kg of tapioca starch is weighed and dispersed in a mixed solvent of ethanol and isopropanol with an ethanol content of 80%. Add 100kg of sodium hydroxide NaOH evenly, keep the system temperature below 30°C when adding, stir and react for 1 hour after adding; add 290kg of sodium chloroacetate, and etherify at 55°C for 2 hours. Then add 0.2 kg of epichlorohydrin and react at a constant temperature...

Embodiment 2

[0024] The difference between embodiment 2 and embodiment 1 is:

[0025] The composite paste of the present invention is as follows: respectively weigh 400kg of modified starch, 175kg of CMC (DS is 1.05, 1% aqueous solution viscosity 1500mpa.s), 100kg of modified guar gum and mix evenly, drop into 80% ethanol Disperse evenly in the solution, raise the temperature to 45°C, add 13.5kg fatty alcohol polyoxyethylene ether, stir and react at constant temperature for 2.5 hours, centrifuge, dry and pulverize to obtain the composite printing paste.

[0026] The preparation process of the modified tapioca starch used in the present invention is as follows: 400 kg of tapioca starch is weighed and dispersed in a mixed solvent of ethanol and isopropanol with an ethanol content of 80%. Add 160kg of sodium hydroxide evenly, keep the system temperature below 30°C when adding, stir and react for 1.5 hours after adding, then add 300kg of sodium chloroacetate, and react at 60°C for 3 hours. Th...

Embodiment 3

[0029] The difference between embodiment 3 and embodiment 1 is:

[0030] The composite paste of the present invention is as follows: respectively weigh 400kg of modified starch, 150kg of CMC (DS is 1.1, viscosity of 1% aqueous solution 1800mpa.s), 150kg of modified guar gum and mix evenly, drop into 80% ethanol Disperse evenly in the solution, raise the temperature to 50°C, add 10kg of octylphenol polyoxyethylene ether, stir and react at constant temperature for 3 hours, centrifuge, dry and pulverize to obtain the composite printing paste.

[0031] The preparation process of the modified tapioca starch used in the present invention is as follows: 400 kg of tapioca starch is weighed and dispersed in a mixed solvent of ethanol and isopropanol with an ethanol content of 80%. Add 80kg of sodium hydroxide evenly, keep the system temperature below 30°C when adding, stir and react for 2 hours after adding, then add 300kg of sodium chloroacetate, and react at 58°C for 4 hours. Then a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com