Screw type air compressor air inlet valve with features of precise control of opening degree and driving and quick response

An air compressor, screw type technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of impacting the power grid, wasting air power source, unable to achieve continuous and stable supply, etc., to achieve stable operation, reduce Leak point, the effect of saving and controlling gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

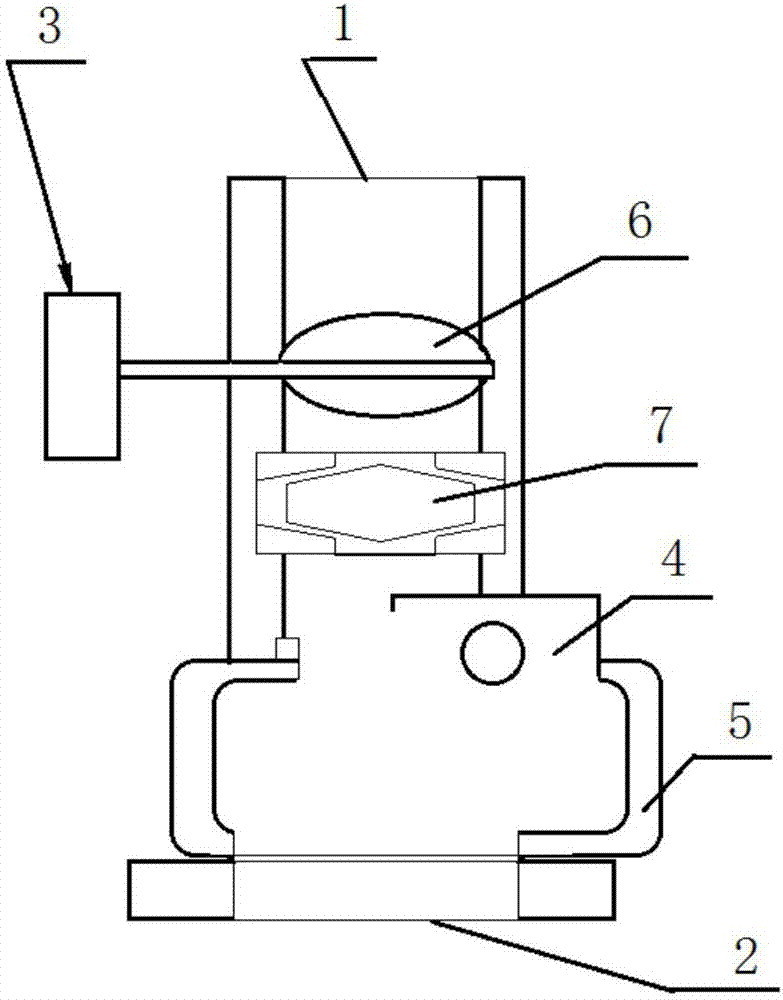

[0030] Example: as attached figure 1 And attached Figure 5 As shown, an air inlet 1 is installed on the upper part of the valve body 5, an air outlet 2 is installed on the lower part of the valve body 5, a drive controller 3 is installed on the side of the valve body 5, a butterfly valve 6 is installed on the upper part of the air inlet 1, and the butterfly valve 6 is connected with the drive controller 3-axis connection, a heavy hammer check valve 7 is installed under the butterfly valve 6 in the air inlet 1, a vent valve 4 is installed on the valve body 5, and the drive controller 3 and the vent valve 4 are connected to the control system.

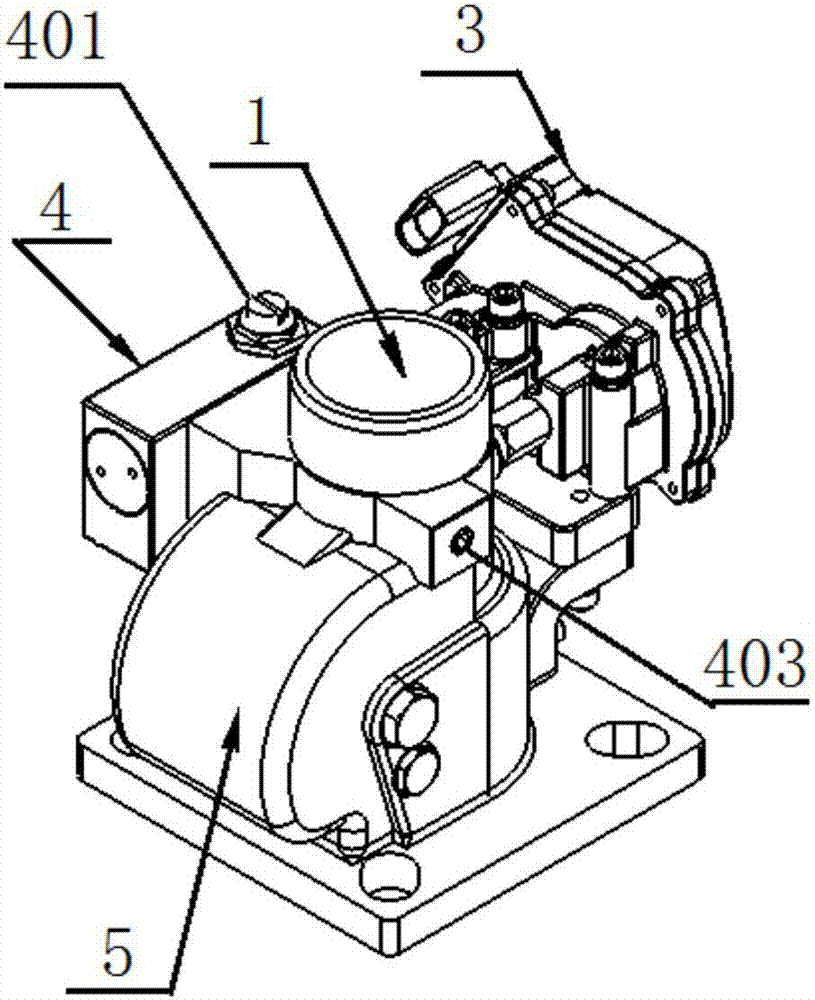

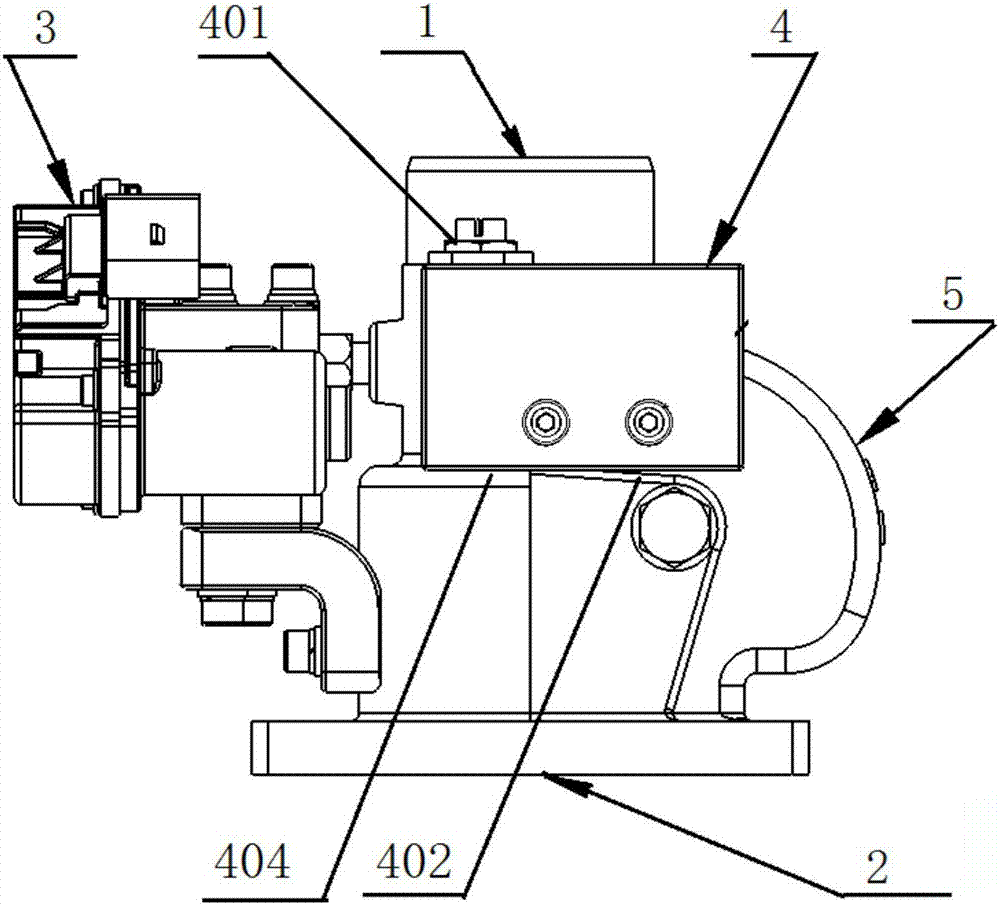

[0031] In the foregoing, as attached figure 2 , attached image 3 And attached Figure 4 As shown, the two ends of the vent valve 4 run through the valve body 5 front and back, the upper side of the vent valve 4 is equipped with an adjusting bolt 401, the left side of the lower end has an air release port 404, the right side of the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com