Medical sterilization air purifier free of material consumption and maintenance

A controller and electrical connection technology, which is applied in the direction of gasification substances, climate change adaptation, air quality improvement, etc., can solve the problems of difficult maintenance process, increase of users, and inability to kill drug-resistant bacteria, etc., so as to avoid cleaning and maintenance costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

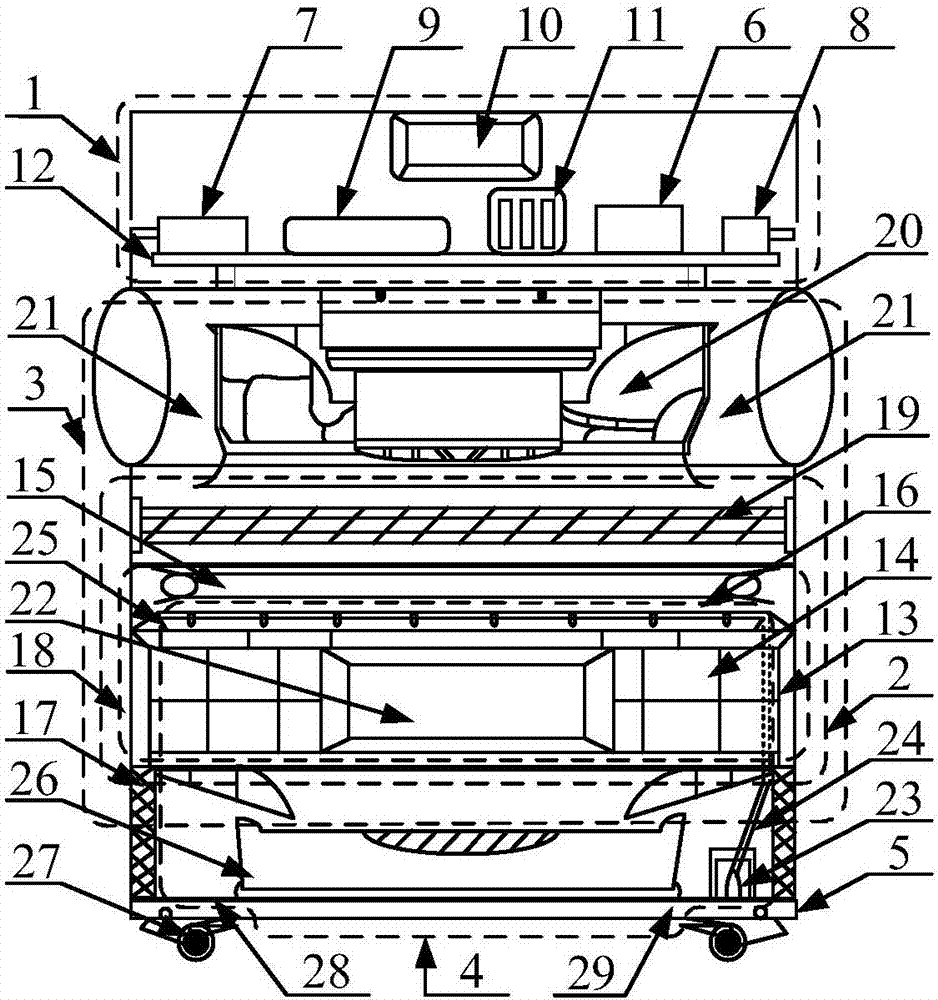

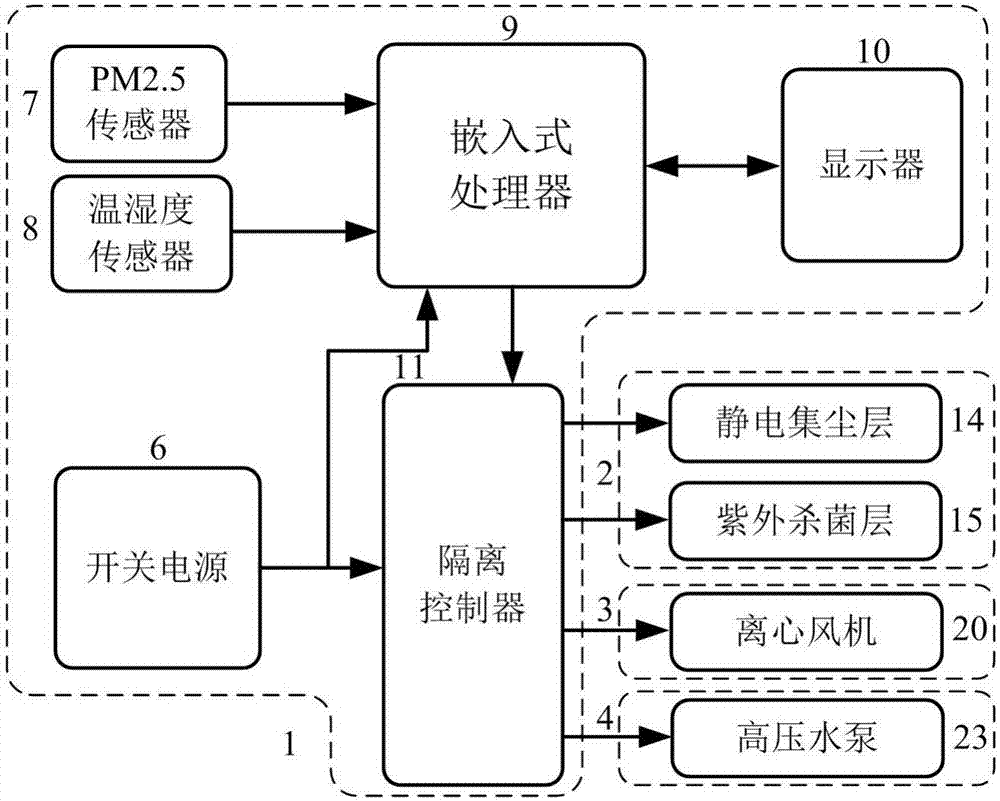

[0015] A medical sterilizing air purifier without consumables and maintenance, comprising: an electrical control system 1, a sterilizing purification cabin 2, an air duct system 3, a cleaning system 4, a housing and a frame 5;

[0016] The shell and frame 5 are mechanically connected with the electrical control system 1, the sterilization and purification cabin 2, the air duct system 3, and the cleaning system 4 in a supported and fixed manner, forming the mechanical body structure of the medical sterilization air purifier. The electrical control system 1 is electrically connected with the sterilization and purification cabin 2, the air duct system 3, and the cleaning system 4 through electrical signals, controls the sterilization and purification cabin 2, and the air duct system 3 to start the air sterilization and purification functions, adjusts the air flow speed, and controls the cleaning system 4 , The air duct system 3 starts the automatic cleaning function, which constit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com