Rice meal low-temperature anti-aging agent

An anti-aging agent, rice flour technology, applied in food ingredients as emulsifiers, food science, food preservation and other directions, can solve the problems of no preservation application, narrow application range, etc., to reduce water loss, improve water locking ability, Effect of preventing hardening in cryopreservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The low-temperature storage anti-aging agent for rice flour in this example is prepared by mixing sodium stearate (SSL), monoglyceride (GMS), sodium alginate, and β-cyclodextrin through high-speed shearing.

[0019] Weigh 27~30g of rice flour, mix it with the above anti-aging agent, gradually add the predetermined amount of water under the action of a homogenizer, and cook to obtain rice flour products. Control the rice flour products to contain 0.2wt% sodium stearate lactate (SSL) , 0.2wt% monoglyceride (GMS), 0.1wt% sodium alginate, 0.15wt% β-cyclodextrin.

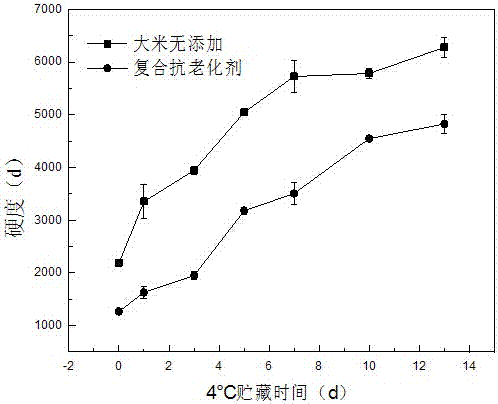

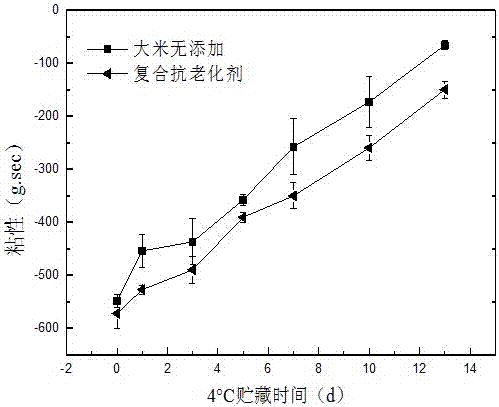

[0020] The rice flour product obtained by the above method was stored at 4°C, and its hardness and viscosity changed as follows: Figure 1~2 shown.

Embodiment 2

[0022] The low-temperature storage anti-aging agent for rice flour in this example is prepared by mixing sucrose ester (SE), guar gum, sodium alginate and β-cyclodextrin by high-speed shearing.

[0023] Weigh 27-30g of rice flour, mix it with the above anti-aging agent, gradually add the predetermined amount of water under the action of a homogenizer, and cook to obtain rice flour products. Control the rice flour products to contain 0.12wt% sucrose ester (SE), 0.1 wt% guar gum, 0.16wt% sodium alginate, 0.15wt% β-cyclodextrin.

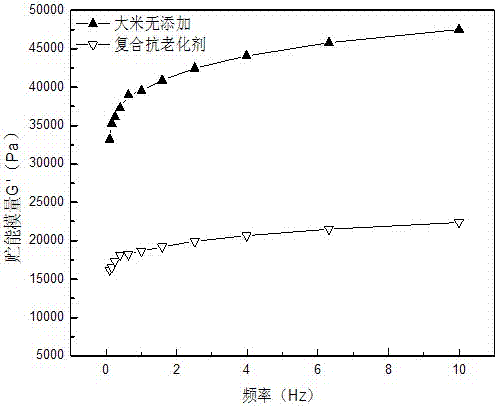

[0024] The storage modulus of the rice flour product obtained by the above method was stored at 4°C as follows: image 3 shown.

[0025] The storage modulus G' curve of starch gel measured by rheometer can reflect the aging degree of starch. G' represents the elastic properties of energy storage and recovery, and generally the larger the value of G', the higher the aging degree of starch. On the 7th day of storage at 4°C, the G' (18630 Pa) at 1 Hz ...

Embodiment 3

[0027] The low-temperature storage anti-aging agent for rice flour in this example is prepared by mixing sodium stearate (SSL), monoglyceride (GMS), sodium alginate, and konjac glucoside through high-speed shearing.

[0028] Weigh 27~30g of rice flour, mix it with the above anti-aging agent, gradually add the predetermined amount of water under the action of a homogenizer, and cook to obtain rice flour products. Control the rice flour products to contain 0.2wt% sodium stearate lactate (SSL) , 0.25wt% monoglyceride (GMS), 0.15wt% sodium alginate, 0.26wt% konjac glucoside.

[0029] The rice flour product obtained by the above method was stored at 4°C, and its water activity changed as follows: Figure 4 shown.

[0030] With the prolongation of storage time, the water activity of the samples gradually decreased. The change of water activity is mainly related to the change of free water content, which is an index to measure the quality of starch products. Comparing the control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com