Automobile diesel pump tail gas treatment pump diaphragm and vulcanization forming mold and manufacturing method thereof

A technology of tail gas treatment and vulcanization molding, which is applied in the fields of rubber, metal and non-metal processing. It can solve the problems of easy wrinkling of reinforced fibers, low production efficiency of pump membrane, and fracture of pump membrane, so as to save the need for trimming the surface of the skeleton. process, improve product quality and production efficiency, and prevent wrinkling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

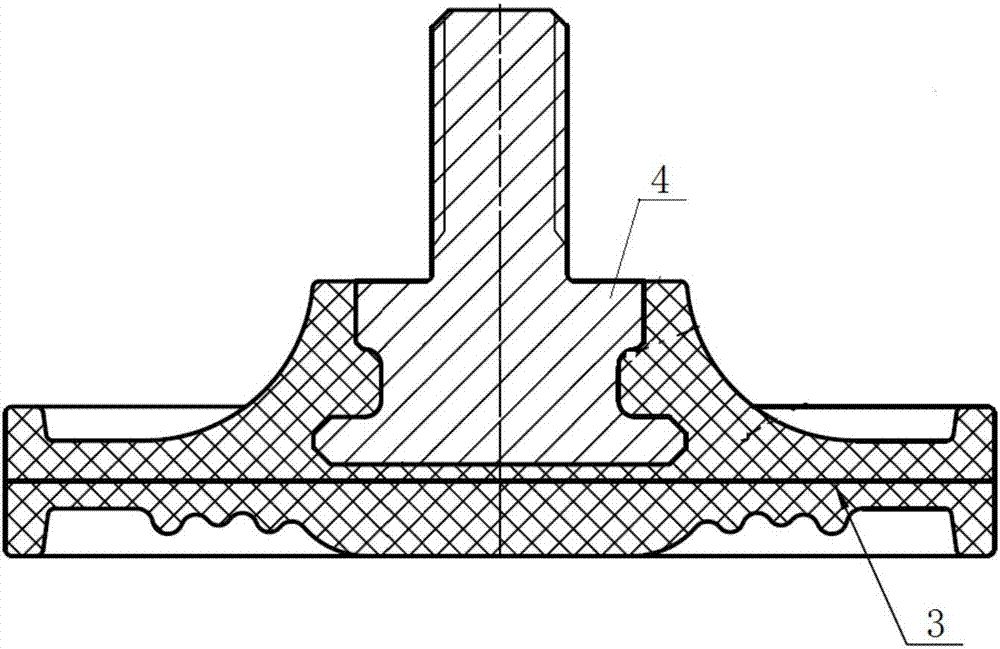

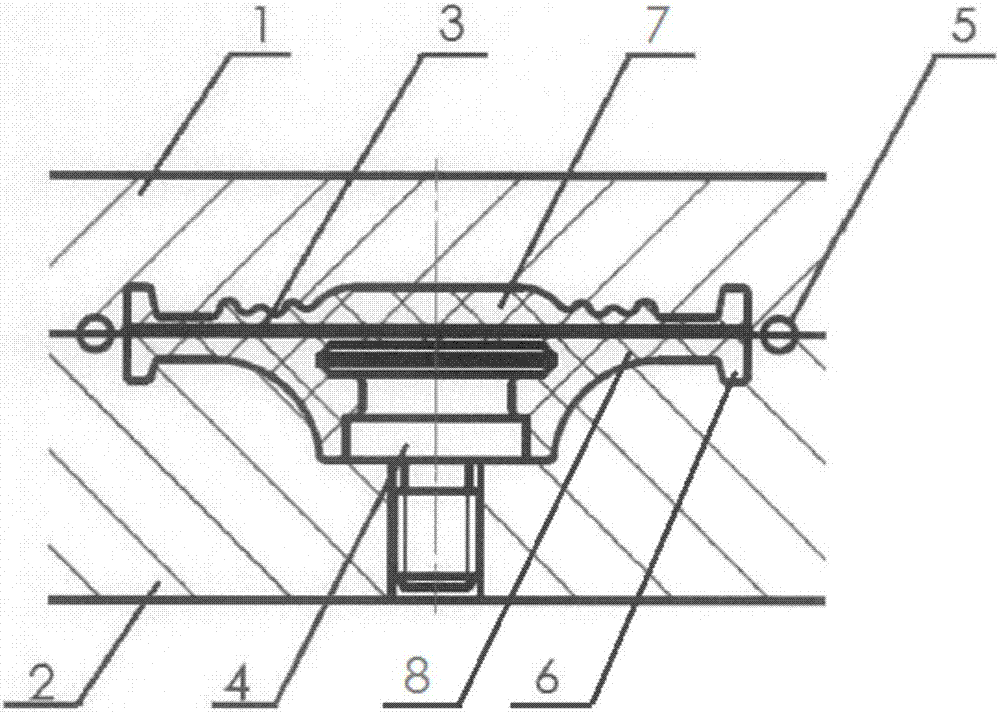

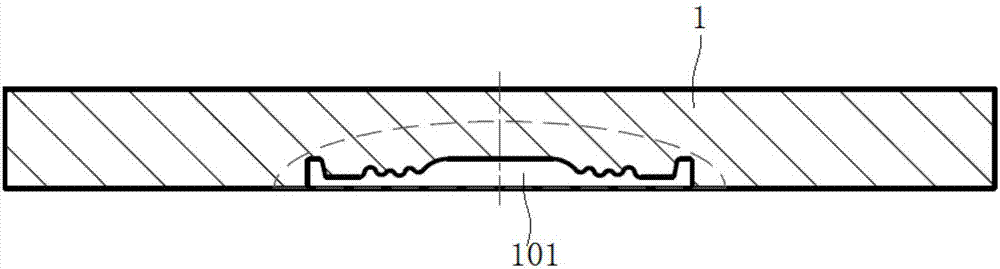

[0055] In conjunction with the accompanying drawings, the vulcanization molding die of a kind of EPDM rubber in this embodiment combined with metal and reinforcing fiber for the exhaust gas treatment pump membrane of automobile diesel pump includes an upper mold 1 and a lower mold 2, and the lower surface of the upper mold 1 is set There is an upper mold cavity 101, the upper surface of the lower mold 2 is provided with a lower mold cavity 201, and the bottom of the lower mold cavity 201 is vertically provided with a card slot 202, and the upper mold cavity 101 and the lower mold cavity 201 are molded together to form Rubber cavity 6, on the inner surface of rubber cavity 6, a circle of O-shaped edge tear rib 5 is arranged on the edge of reinforcing fiber 3, the horizontal width of described O-shaped edge tear rib 5 is 1mm, and the protrusion height is 1mm. It is 0.1 mm from the edge of the rubber cavity 6 . The rubber-coated part of the metal skeleton 4 of the pump membrane t...

Embodiment 2

[0069] The vulcanization molding die of a kind of automobile diesel pump tail gas treatment pump film of the present embodiment, its structure is basically the same as embodiment 1, and its difference is: the horizontal width of O-shaped edge tear rib 5 is 2mm, and the height of protrusion is 2mm, and its distance The edge of the rubber cavity 6 is 0.2mm.

[0070]The vulcanization molding die of this embodiment is used to manufacture the pump membrane for automobile diesel pump exhaust gas treatment. The steps are basically the same as in Example 1, except that the thickness of the reinforcing fiber 3 in step 1 is 0.3 mm; The material blank of the pump membrane surface body rubber material 8 is composed of the following components in parts by weight:

[0071] Components of the pump membrane body compound used in Table 2 Example 2

[0072]

[0073]

[0074] In Step 3, the vulcanization temperature of the vulcanizer is controlled at 180°C, the vulcanization time is contro...

Embodiment 3

[0076] A kind of vulcanization forming mold of the automobile diesel pump tail gas treatment pump membrane combined with EPDM rubber, metal and reinforcing fiber of this embodiment, its structure is the same as that of embodiment 1. The manufacturing method of the automobile diesel pump tail gas treatment pump membrane of the present embodiment adopts the vulcanization molding die of the present embodiment to manufacture the pump membrane, and the steps are basically the same as those of the embodiment 1, the difference mainly lies in that the thickness of the reinforcing fiber 3 in the first step is 0.4mm; the raw materials of the pump membrane bottom body rubber material 7 and the pump membrane surface body rubber material 8 are composed of the following components by mass percentage:

[0077] Components of the pump membrane body compound used in Table 3 Example 3

[0078] Raw material name % EPDM rubber 60 High wear-resistant carbon black: 20 Se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com