Antibacterial polypropylene master batch and preparation method thereof

A technology of antibacterial polypropylene and polypropylene is applied in the field of efficient and environmentally friendly antibacterial polypropylene masterbatch and its preparation, so as to achieve the effects of improving antibacterial properties, stable performance and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

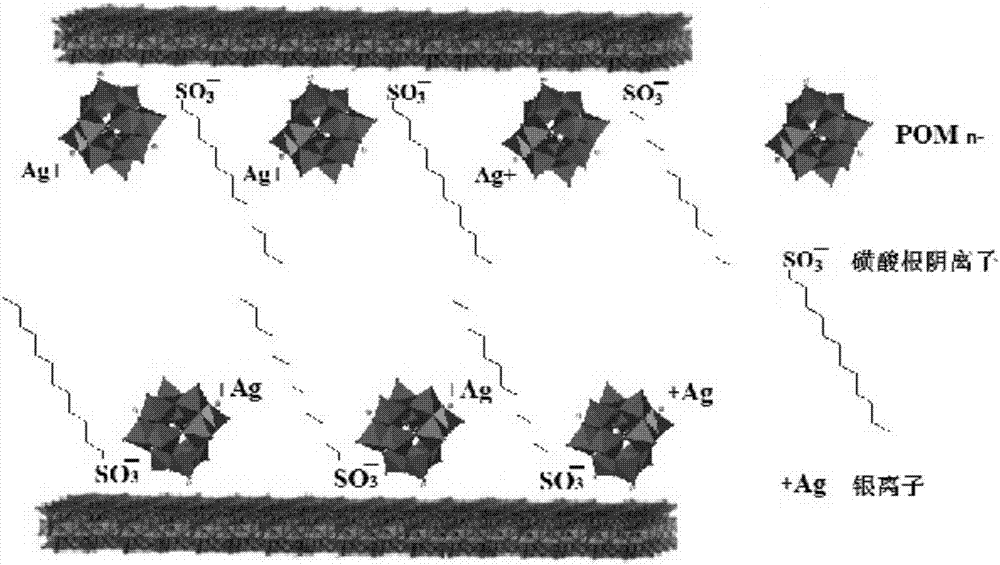

Method used

Image

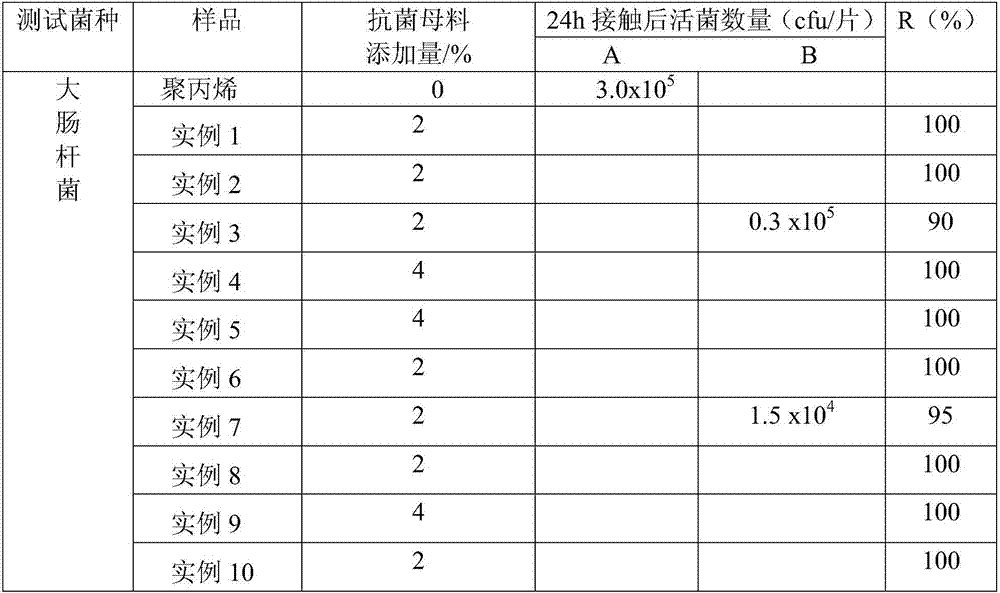

Examples

Embodiment 1

[0026] First, the maleate-branched polypropylene with a grafting rate of 0.8% is crushed into powder with a particle size of 200 mesh, and then 400g of antibacterial agent, 200g of compatibilizer, 4g of antioxidant 1076, and 16g of calcium stearate are added to the high-speed mixer In the process, after stirring and mixing for 0.5h, add 380g polypropylene to continue mixing for 0.5h, dry at 60°C after starting the material, and then melt, extrude, and granulate through a twin-screw extruder to obtain 1000g of highly efficient and environmentally friendly antibacterial polypropylene. Acrylic masterbatch finished product.

Embodiment 2

[0028]First, the maleate branched polypropylene with a grafting rate of 0.9% is crushed into powder with a particle size of 250 mesh, and then 450g of antibacterial agent, 100g of compatibilizer, 20g of antioxidant 1010, and 30g of zinc stearate are added to the high-speed mixer In the process, after stirring and mixing for 0.5h, add 400g polypropylene and continue mixing for 0.6h. After starting the material, dry it under vacuum at 80°C, and then melt, extrude and granulate through a twin-screw extruder to obtain 1000g of highly efficient and environmentally friendly antibacterial Finished polypropylene masterbatch.

Embodiment 3

[0030] First, the maleate branched polypropylene with a grafting rate of 1.0% is pulverized into powder with a particle size of 300 mesh, then 300g of antibacterial agent, 150g of compatibilizer, 4g of antioxidant 1076, 1g of antioxidant 626, and 45g of polyethylene Add the wax into the high-speed mixer, stir and mix for 1 hour, add 500g polypropylene and continue mixing for 0.8 hours, dry at 90°C after starting the material, and then melt, extrude, and granulate through a twin-screw extruder to obtain 1000g high-efficiency Environmentally friendly antibacterial polypropylene masterbatch finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grafting rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com