Flexible magnetron sputtering coating transverse uniformity control device

A magnetron sputtering coating and magnetron sputtering technology, which is applied in the field of flexible magnetron sputtering coating lateral uniformity control devices, can solve the problem of uneven distribution of sputtering deposition density, affecting the degree of sputtering, and affecting the coating on the surface of the substrate Film thickness consistency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

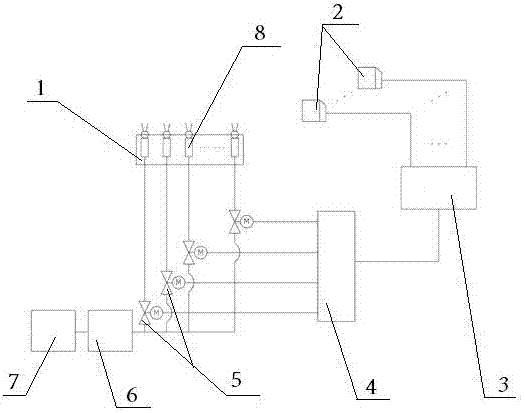

[0017] see figure 1 , the flexible magnetron sputtering coating lateral uniformity control device, including nozzle row 1, magnetron sputtering degree monitoring probe 2, magnetron sputtering degree analysis and comparison device 3, valve opening control device 4, electric valve 5, gas Pressure stabilizing device 6, gas source 7, a plurality of gas nozzles 8 are arranged on the nozzle row, the distance between adjacent gas nozzles 8 is 30 mm, and a plurality of magnetron sputtering degree monitoring probes 2 are arranged at opposite positions, The distance between adjacent magnetron sputtering degree monitoring probes 2 is 60mm. Used to detect the sputtering degree of the gas nozzle 8, the magnetron sputtering degree monitoring probe 2 is connected to the input end of the magnetron sputtering degree analysis and comparison device 3 through the shielded electrical signal output line, and the magnetron sputtering degree analysis and comparison device 3 The output end is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com