Oval ultrasonic machining device with non-contact induction power supply function

一种非接触感应、感应供电的技术,应用在金属加工、金属加工设备、金属加工机械零件等方向,能够解决机械触点易产生火花、无法满足数控加工中心自动换刀、转速受限等问题,达到满足自动换刀条件的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

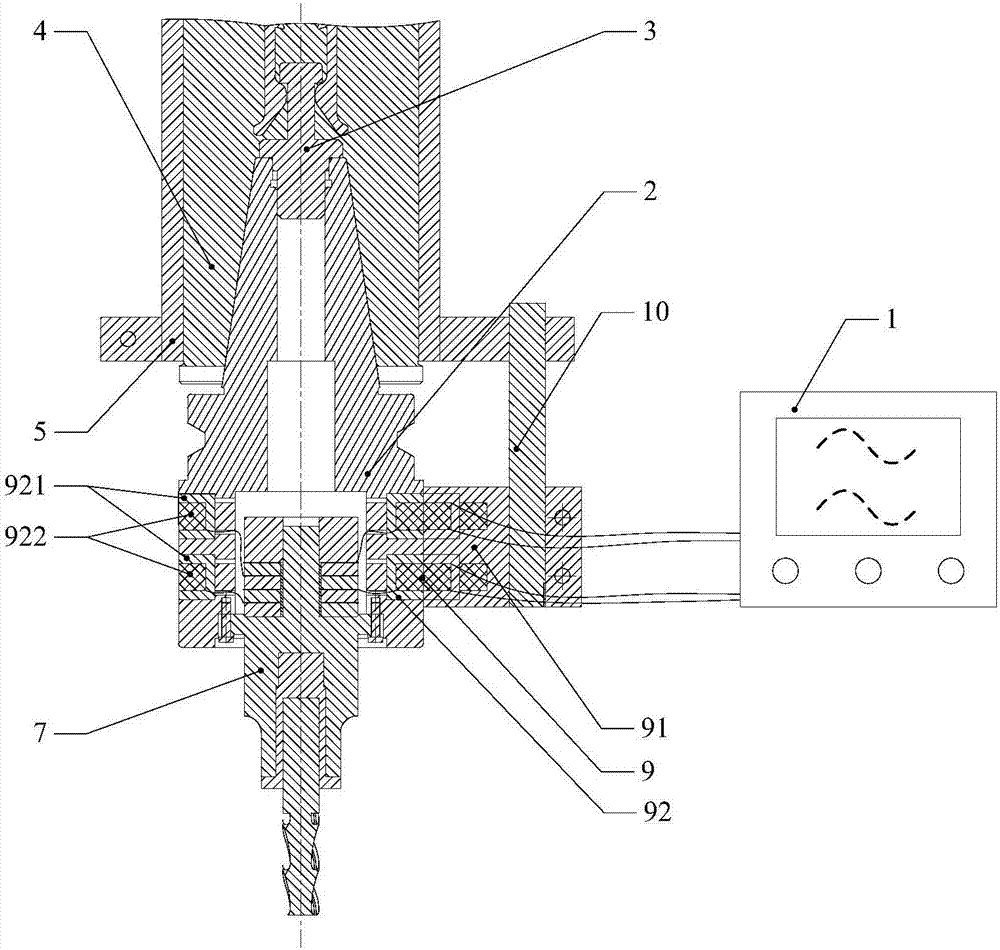

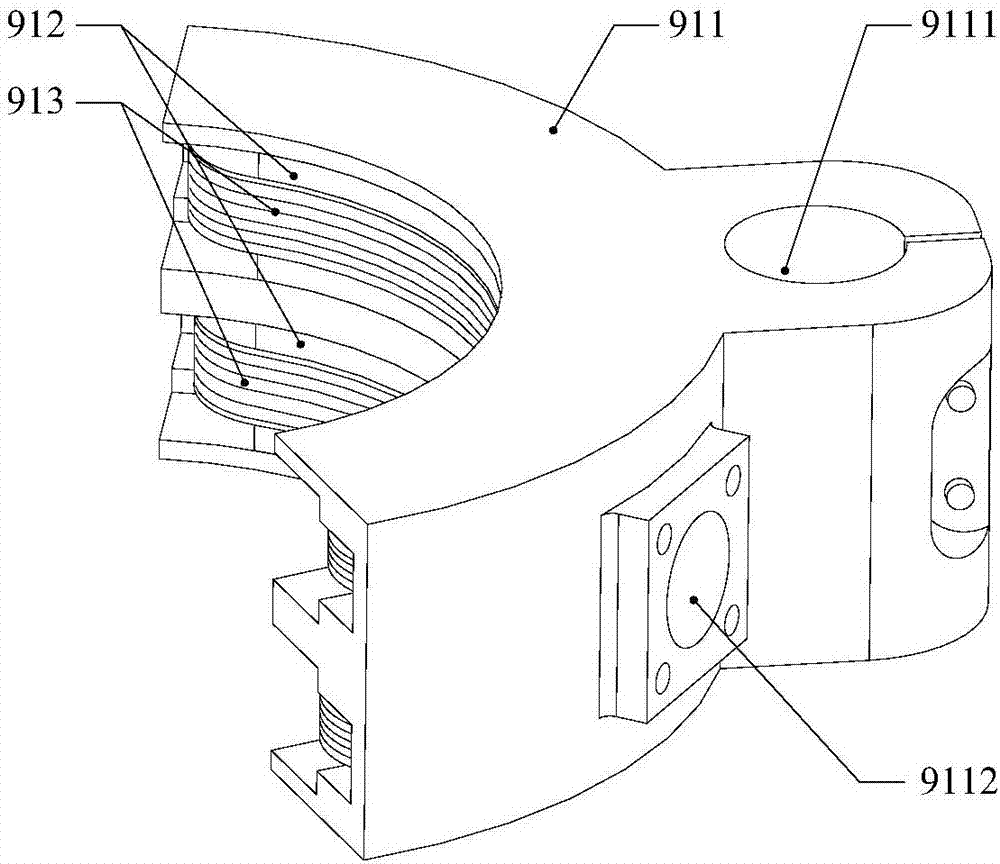

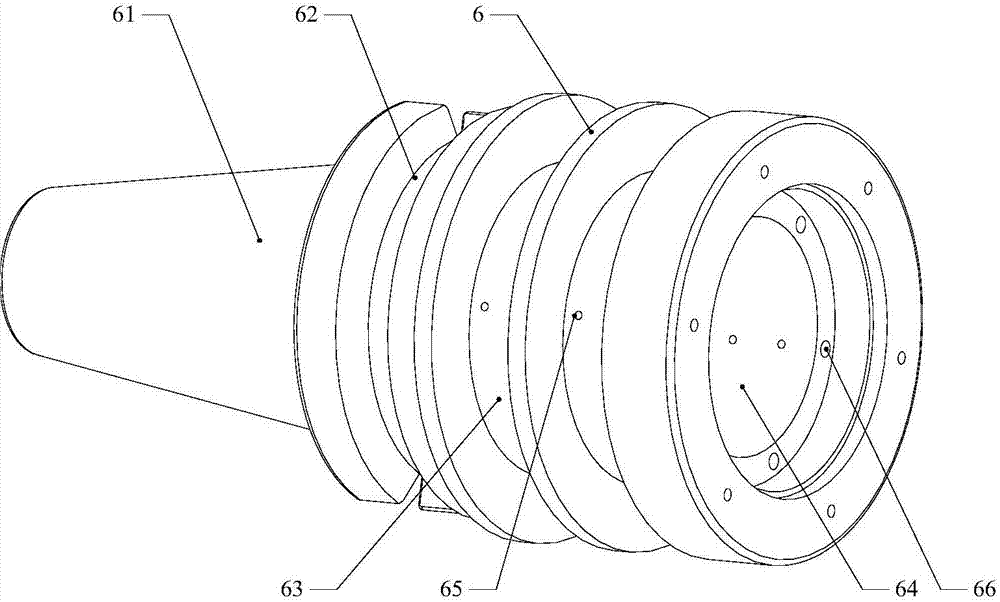

[0045] The preferred embodiments of the present invention are attached figure 1 As shown, it includes an elliptical ultrasonic power supply 1, an induction power supply device 9, an elliptical ultrasonic tool holder 2, and a CNC machining center spindle 4. Attached below figure 1 , 2 , 3 and 4 further describe the present invention.

[0046] The present invention is a non-contact induction power supply elliptical ultrasonic processing device, see figure 1 As shown, it is mainly composed of an induction power supply device 9 and an elliptical ultrasonic tool holder 2; the induction power supply secondary side 92 of the induction power supply device 9 is fixed to the BT tool holder shell 6 of the elliptical ultrasonic tool holder 2, and the induction power supply primary side 91 The outer side of the elliptical ultrasonic tool holder 2 is a concentric circle inside and outside. The two keep a small gap, and are fixed to the spindle seat 5 of the CNC machining center machine tool thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com