Equipment and method for disassembling low-radioactivity folding type waster filter

A low-radioactive, folding technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of high disposal costs, large storage volume, large storage space, etc., and achieve the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is further described below in conjunction with accompanying drawing and embodiment:

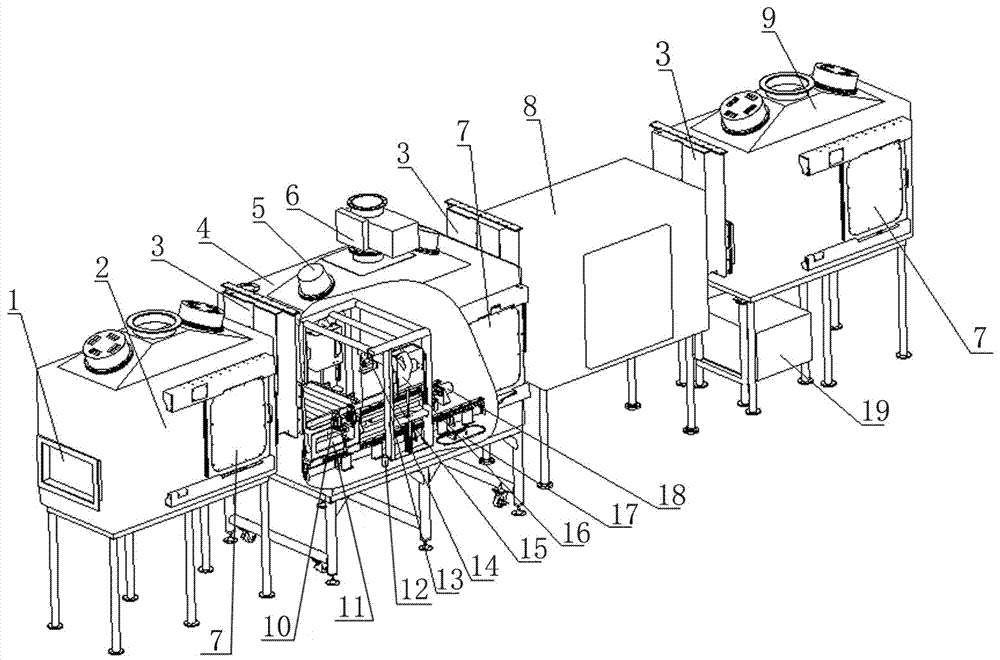

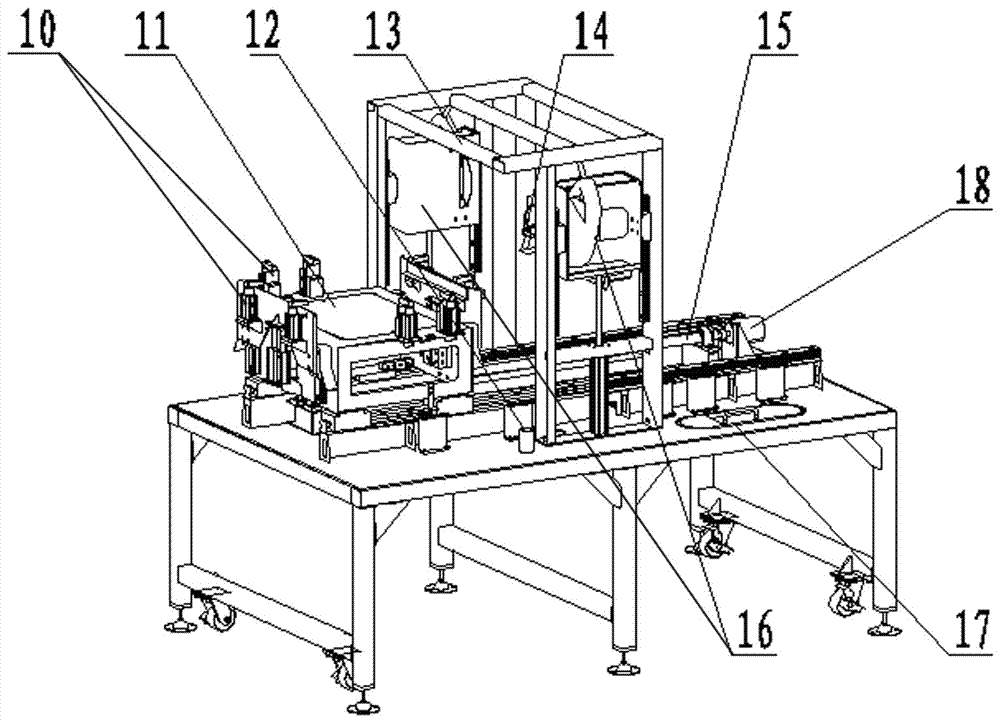

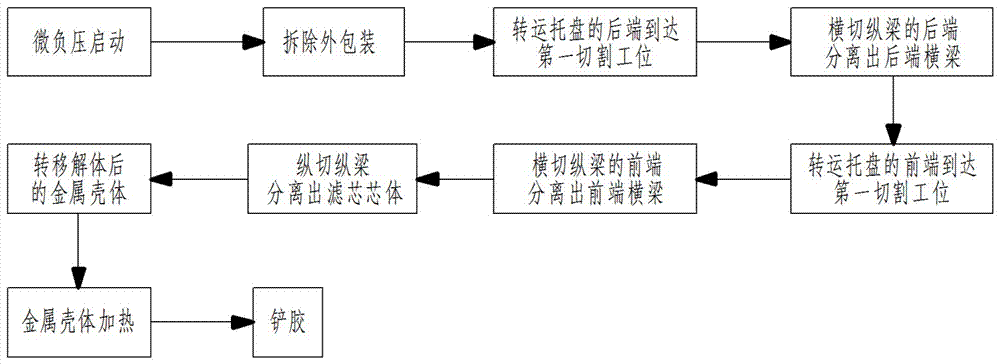

[0034] like figure 1 , figure 2 As shown, the device for dismantling the low-radioactivity folded waste filter of the present invention includes an outer packaging negative that is connected end to end in a straight line, the inner cavity is connected, and the inlet and outlet are intermittently closed through the isolation door 3 respectively. Pressure fume hood 2, dismantling negative pressure fume hood 4, tunnel oven 8 and shoveling negative pressure fume hood 9, and supporting ventilation system, lighting system and control system; A closed door 7 with a push-pull structure is provided, and lighting fixtures 5 and air volume regulating valves 6 are arranged on the top wall of each fume hood (through the air volume regulating valve 6, each negative pressure fume hood can be kept in a slightly negative pressure state; dismantling The air volume regulating val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com