Alpha-Fe2O3 nanorod and Au/alpha-Fe2O3 catalyst, and synthesis and application thereof

A nanorod and catalyst technology, which is applied in the field of porous α-Fe2O3 nanorods and their synthesis, can solve the problems of decreased dispersion and easy sintering of Au nanoparticles at high temperature, and achieves improved thermal stability and dispersion, environmental friendliness, and obvious advantages. The effect of size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

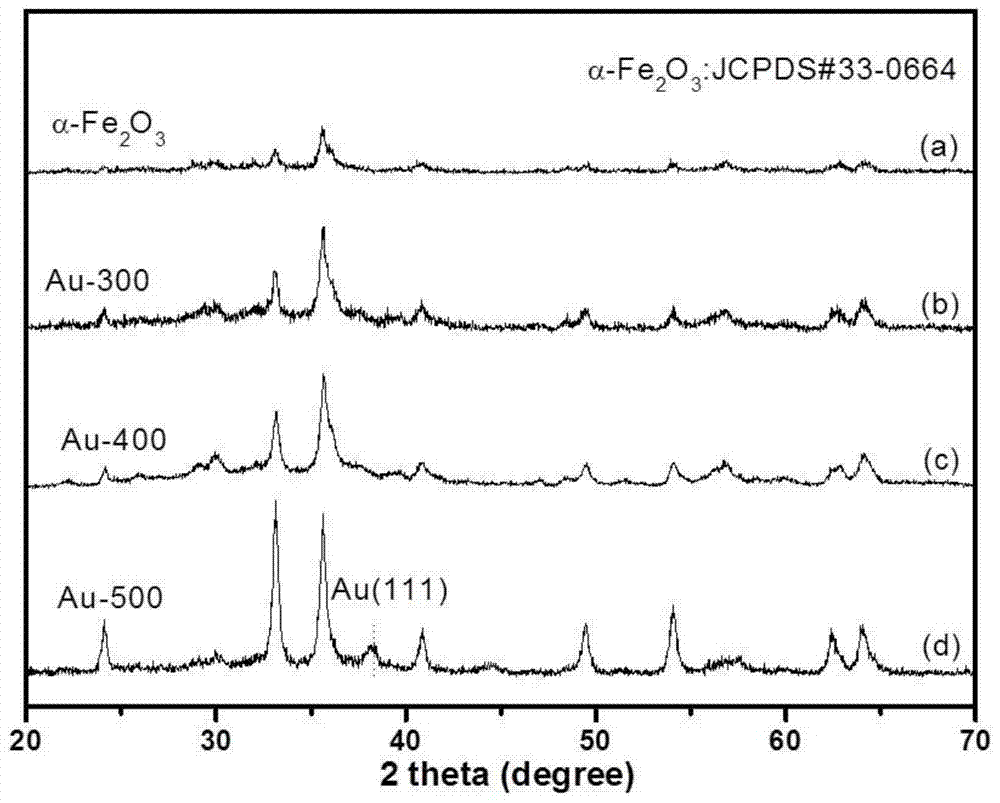

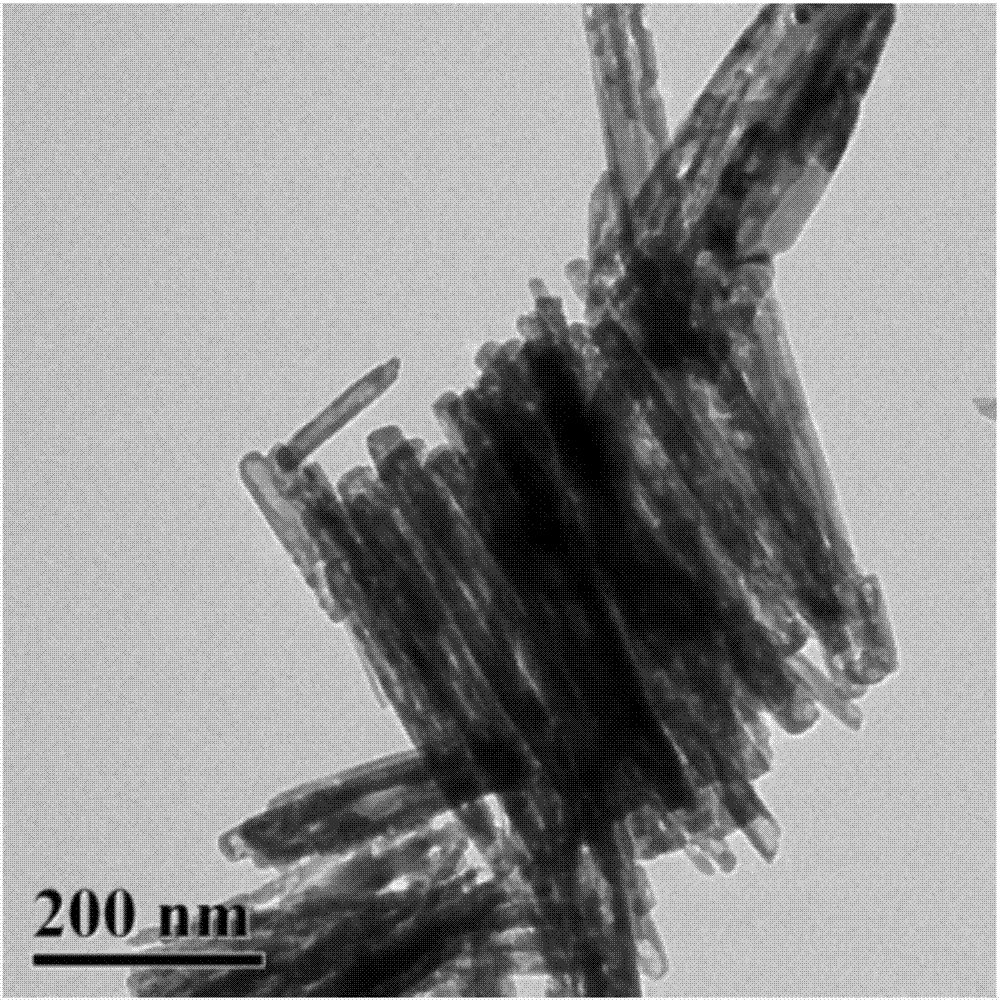

[0047] 5.408g FeCl 3 ·6H 2 O, 11.6g NaCl, 10mL PEG were added to 190mL water, stirred and heated to 120°C; then 200mL 0.2mol / L Na 2 CO 3 After the solution was added to the above solution at a speed of 0.55mL / min (6 hours), continue to stir and age for 1 hour; adjust the pH to 8.0-12.0, filter, wash and dry the aged product, and store it at 500°C Roasted for 5 hours to obtain solid powder. Analyzed as α-Fe by XRD 2 o 3 crystal phase, its XRD spectrum is shown in figure 1 a; TEM images are shown in figure 2 . The results showed that the synthesized α-Fe 2 o 3 The sample has a nanorod structure with a diameter of 40-50nm and a length of 300-500nm, and its specific surface area is 79m 2 / g, the average pore diameter is about 20nm.

Embodiment 2

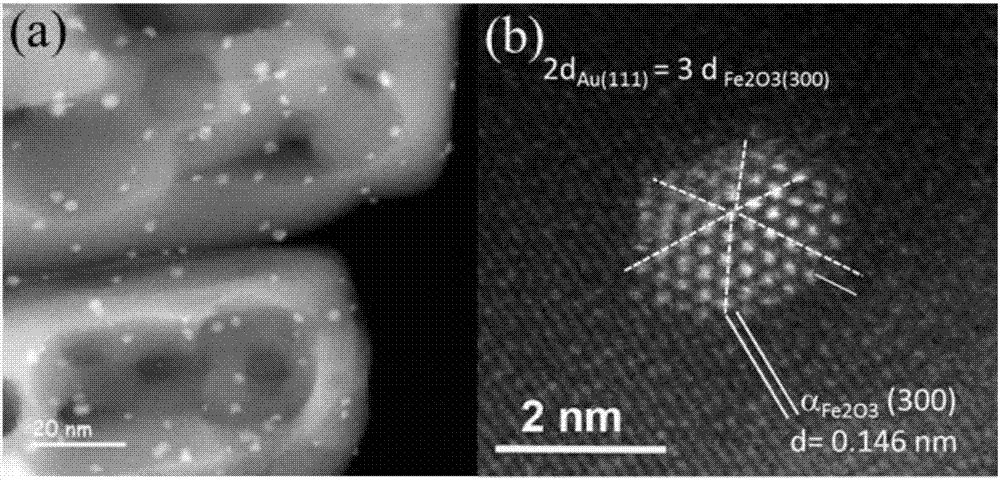

[0049] Get the 1gα-Fe obtained in the implementation case 1 2 o 3 Nanorods dispersed in 300mL containing HAuCl 4 (4.9×10 -4 mol / L) in the aqueous solution, after heating to 80°C, add 60mL of 0.01mol / L Na 2 CO 3 solution, adjust the pH to 5.9. After aging at this temperature for 1 h, after filtering, washing, and drying at 120° C. for 12 h, a solid precursor was obtained. Calcined Au / α-Fe at 300℃ in air for 5h 2 o 3 The catalyst is labeled Au-300, where the loading of Au is 1.6 wt.%. Its XRD spectrum and TEM pictures are shown in figure 1 b and image 3 a; the diameter of the carrier nanorod is 40-50nm, and the length is 300-500nm; the average size of the Au nanoparticles is 2.2nm, further passed through HRTEM ( image 3 b) The analysis revealed that the Au nanoparticles are mainly two-dimensional thin layered structures.

Embodiment 3

[0051] The solid precursor in Example 2 was calcined at 400°C for 5 hours, and the resulting sample was labeled Au-400, and its XRD spectrum and TEM pictures are shown in figure 1 c and Figure 4 a; α-Fe 2 o 3 The morphology and crystal phase of the carrier remain unchanged; the average size of Au nanoparticles is 3.5nm, and its morphology is mainly three-dimensional truncated octahedron ( Figure 4 b).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com