A bioretention tank filter layer filler and processing method

A bioretention tank and filter layer technology, applied in chemical instruments and methods, biological water/sewage treatment, drainage structures, etc., can solve the problems of small permeability coefficient, large fluctuation range, exceeding design requirements, etc., and achieve small permeability coefficient, The effect of improving stability and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of bioretention tank filter layer filler of the present invention comprises the composition of following percentage by weight:

[0034]

[0035] In this embodiment, the sand materials are all Yellow River sand, the fineness modulus of selected coarse sand is 3.702, the fineness modulus of medium sand is 1.887, the fineness modulus of fine sand is 0.625, and the natural organic matter is nutrient soil, which is The pine needles are composted and fermented after crushing, and the mass percentage of organic matter per unit mass is 67%.

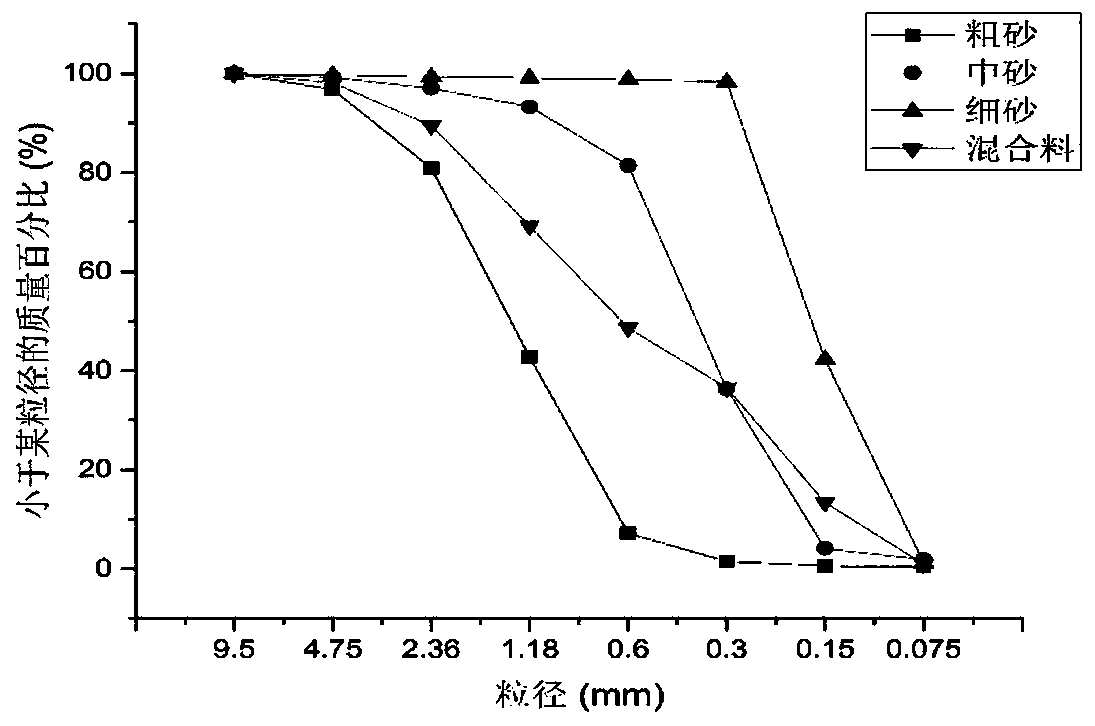

[0036] Dry the above-mentioned coarse sand, medium sand, and fine sand to an initial moisture content of 1%, mix them with nutrient soil, and use a mixer to stir them evenly to form fillers. image 3 It is the gradation curve of the raw materials and the mixture of Example 1. The coarse, medium and fine sand used are all continuously graded Yellow River sand, and the gradation of the mixture is close to a straight line, which sho...

Embodiment 2

[0038] A kind of bioretention tank filter layer filler of the present invention comprises the composition of following percentage by weight:

[0039]

[0040] In this embodiment, the sand materials are all Yellow River sand, the fineness modulus of selected coarse sand is 3.702, the fineness modulus of medium sand is 1.887, the fineness modulus of fine sand is 0.625, and the natural organic matter is nutrient soil, which is The leaves are composted and fermented after crushing, and the mass percentage of organic matter per unit mass is 73%.

[0041]The above-mentioned coarse sand, medium sand and fine sand are dried to an initial moisture content of 2% and mixed with nutrient soil, and stirred evenly by a mixer to form a filler.

[0042] Figure 4 It is the gradation curve of the raw material and the mixture of Example 2. The coarse, medium and fine sands used are all continuously graded Yellow River sand, and the gradation of the mixture is close to a straight line, which...

Embodiment 3

[0047] A kind of bioretention tank filter layer filler of the present invention comprises the composition of following percentage by weight:

[0048]

[0049] In this embodiment, the sand materials are all Yellow River sand, the fineness modulus of selected coarse sand is 3.702, the fineness modulus of medium sand is 1.887, the fineness modulus of fine sand is 0.625, and the natural organic matter is nutrient soil, which is The product of pine needle leaves after composting fermentation, the mass percent of organic matter per unit mass is 85%.

[0050] The above-mentioned coarse sand, medium sand, and fine sand are dried to an initial moisture content of 2.5% and then mixed with nutrient soil, and stirred evenly by a mixer to form a filler.

[0051] Figure 5 It is the gradation curve of the raw material and the mixture of Example 3. The coarse, medium and fine sands used are all continuously graded Yellow River sand, and the gradation of the mixture is close to a straight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com