Zinc metal organic framework material, and preparation method and application thereof

An organic framework and zinc metal technology, applied in the direction of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problem of difficult specific and selective adsorption of activated carbon, and achieve good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

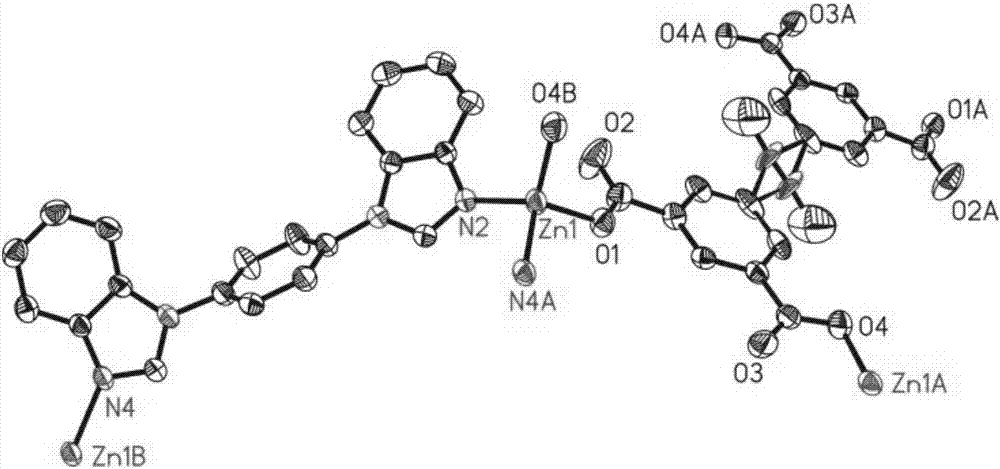

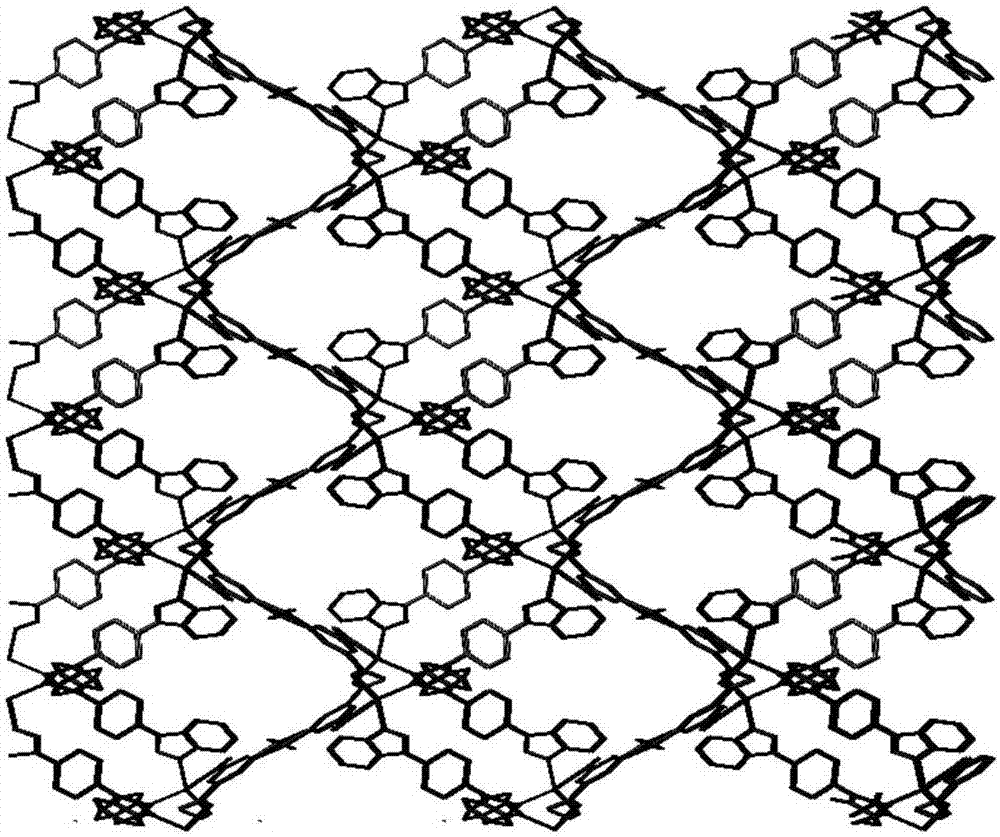

[0021] The preparation method of the zinc metal organic framework material of embodiment 1 comprises the following steps:

[0022] (1) Weigh 59.4mg of zinc nitrate hexahydrate, 18.7mg of azobenzene-3,3',5,5'-tetracarboxylic acid and 15mg of 1,4-dibenzimidazole-benzene, add Into the polytetrafluoroethylene lined reactor;

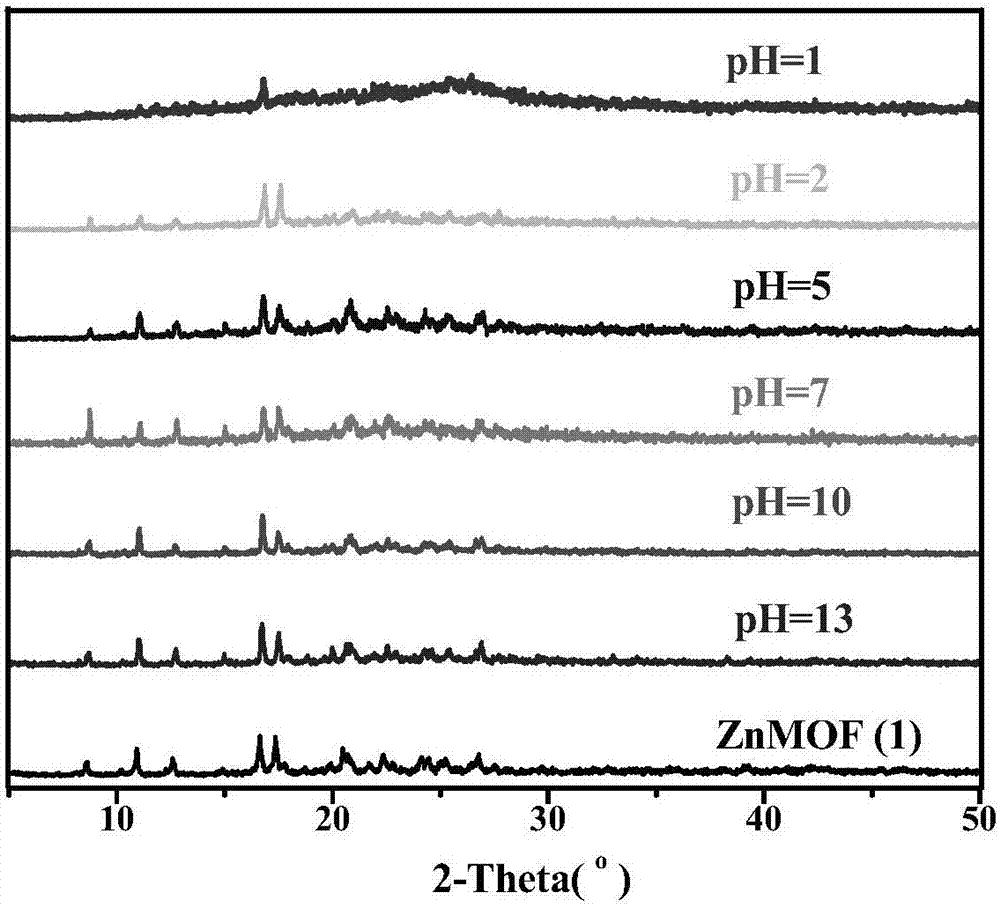

[0023] (2) Add 3mL of N,N-dimethylacetamide into the reaction kettle, stir for 30min to mix the mixture evenly, then adjust the pH value of the mixture to 3.5 with tetrafluoroboric acid, then put the reaction kettle into the stainless steel The outer tank is sealed, and the stainless steel outer tank is heated from room temperature to 120 °C at a rate of 0.3 °C / min, and reacted at 120 °C for 4 days, and finally cooled to room temperature at a rate of 0.1 °C / min to obtain yellow flaky crystals. After washing with N,N-dimethylacetamide and drying, the zinc metal organic framework material is prepared, which is recorded as ZnMOF crystal, and its molecular formu...

Embodiment 2

[0024] The preparation method of the zinc metal organic framework material of embodiment 2 comprises the following steps:

[0025] (1) Weigh 59.4mg of zinc nitrate hexahydrate, 18.7mg of azobenzene-3,3',5,5'-tetracarboxylic acid and 15mg of 1,4-dibenzimidazole-benzene, add Into the polytetrafluoroethylene lined reactor;

[0026] (2) Add 3mL of N,N-dimethylacetamide into the reaction kettle, stir for 60min, mix the mixture evenly, adjust the pH value of the mixture to 4 with tetrafluoroboric acid, then put the reaction kettle into stainless steel The outer tank is sealed, and the stainless steel outer tank is heated from room temperature to 120 °C at a rate of 0.4 °C / min, and reacted at 120 °C for 4 days, and finally cooled to room temperature at a rate of 0.3 °C / min to obtain yellow flaky crystals. After washing with N,N-dimethylacetamide and drying, the zinc metal organic framework material is prepared, which is recorded as ZnMOF crystal, and its molecular formula is C 28 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com