Method for preparing fig extract through molecular distillation

A fig extract and molecular distillation technology, which is applied in food science, fat production, tobacco, etc., can solve the problems of large loss of aroma components of fig extract, loss of aroma components and small molecule aroma substances, and impact on aroma quality, etc. Achieve the effect of improving the evaluation effect, retaining the fragrance and sweetness, and excellent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

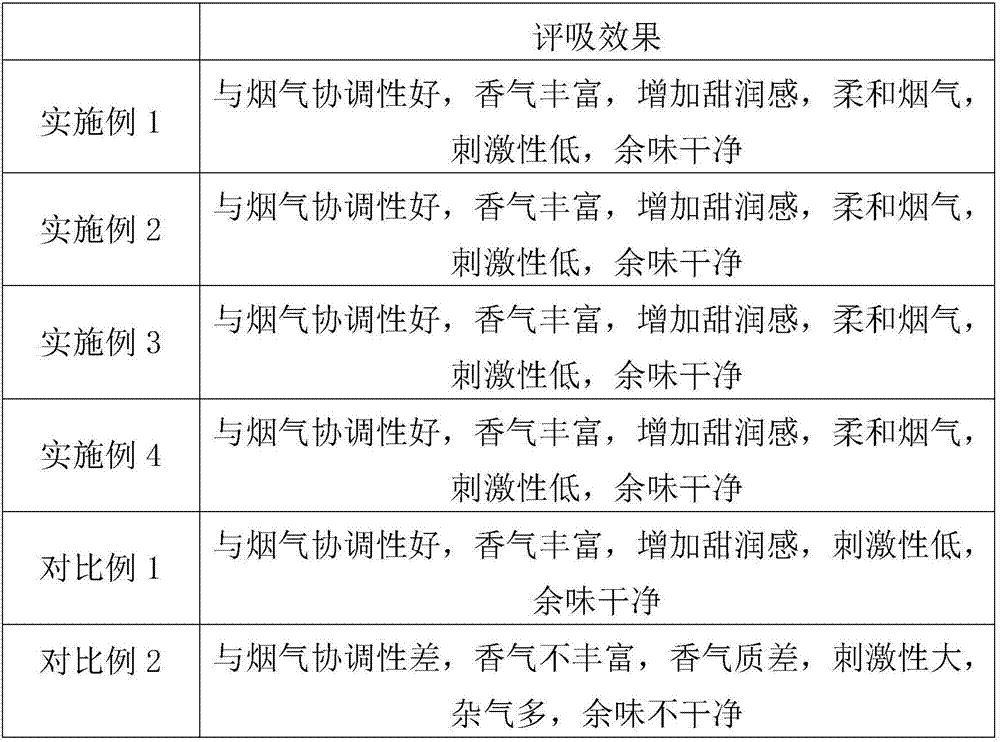

Examples

Embodiment 1

[0025] A method for preparing fig extract by molecular distillation, comprising the following steps:

[0026] (1) Pre-treatment: removing impurities and crushing the fig raw material;

[0027] (2) Ultrasonic extraction once: place the crushed fig raw material in ultrasonic extraction equipment, add 5 times of distilled water to it by weight, and add pectinase of 0.1‰ raw material weight, and then carry out ultrasonic-assisted low temperature to the active ingredients of fig Leaching, the frequency of the ultrasonic extraction is 150KHz, the temperature is 30°C, and the extraction time is 60min;

[0028] (3) Inactivation and suction filtration: heat up the ultrasonically extracted solution to 75°C, keep it for 10 minutes for inactivation treatment, then filter the ultrasonically extracted solution to obtain the initial fig extract, and collect the filter residue for later use;

[0029] (4) Secondary ultrasonic extraction: the filter residue collected in step (3) is placed in u...

Embodiment 2

[0035] A method for preparing fig extract by molecular distillation, comprising the following steps:

[0036] (1) Pre-treatment: removing impurities and crushing the fig raw material;

[0037] (2) Ultrasonic extraction once: place the crushed fig raw material in ultrasonic extraction equipment, add 8 times of distilled water to it by weight, and add pectinase of 0.5‰ raw material weight, and then carry out ultrasonic-assisted low temperature to the active ingredients of fig Extraction, the frequency of the ultrasonic extraction is 200KHz, the temperature is 50°C, and the extraction time is 120min;

[0038] (3) Inactivation and suction filtration: heat up the ultrasonically extracted solution to 85°C, keep it for 20 minutes for inactivation treatment, then filter the ultrasonically extracted solution to obtain the initial fig extract, and collect the filter residue for later use;

[0039] (4) Secondary ultrasonic extraction: the filter residue collected in step (3) is placed i...

Embodiment 3

[0045] A method for preparing fig extract by molecular distillation, comprising the following steps:

[0046] (1) Pre-treatment: removing impurities and crushing the fig raw material;

[0047](2) Ultrasonic extraction once: place the crushed fig raw material in ultrasonic extraction equipment, add 7 times of distilled water to it by weight, and add pectinase of 0.4‰ raw material weight, and then carry out ultrasonic-assisted low temperature to the active ingredients of fig Extraction, the frequency of the ultrasonic extraction is 176KHz, the temperature is 42°C, and the extraction time is 85min;

[0048] (3) Inactivation and suction filtration: heat up the ultrasonically extracted solution to 81° C., keep it for 16 minutes for inactivation treatment, then filter the ultrasonically extracted solution to obtain the initial fig extract, and collect the filter residue for later use;

[0049] (4) Secondary ultrasonic extraction: the filter residue collected in step (3) is placed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com