Stirling electric generator with inserted tube bundle heat regenerator

A regenerator and generator technology, which is applied to machines/engines, hot gas variable capacity engine devices, engine components, etc., can solve the problems of large energy consumption and pollution of silicon light panels, so as to improve energy utilization, reduce pollution, The effect of increasing heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

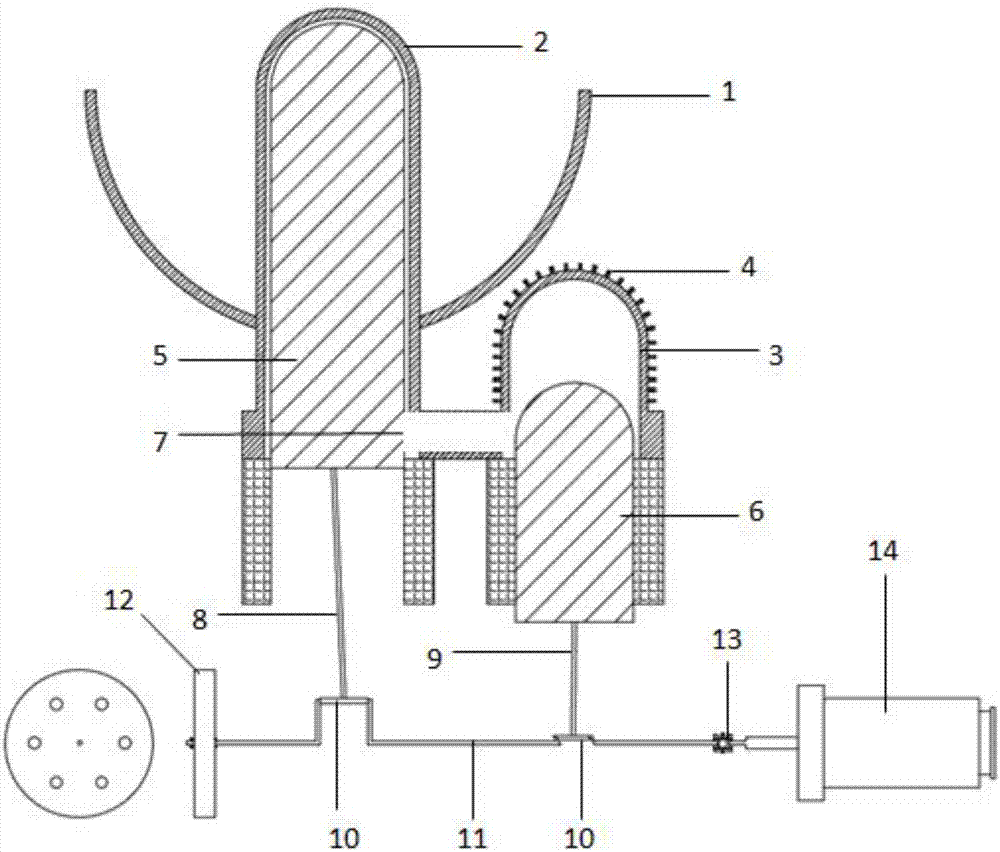

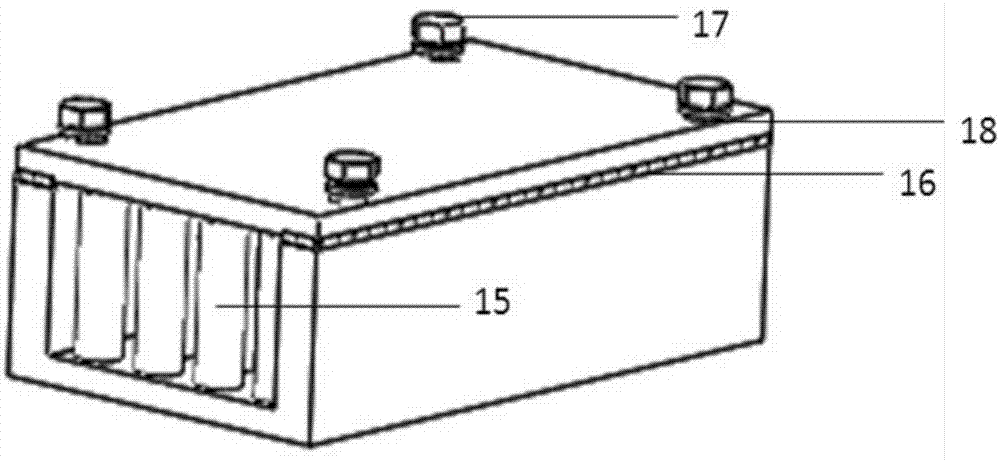

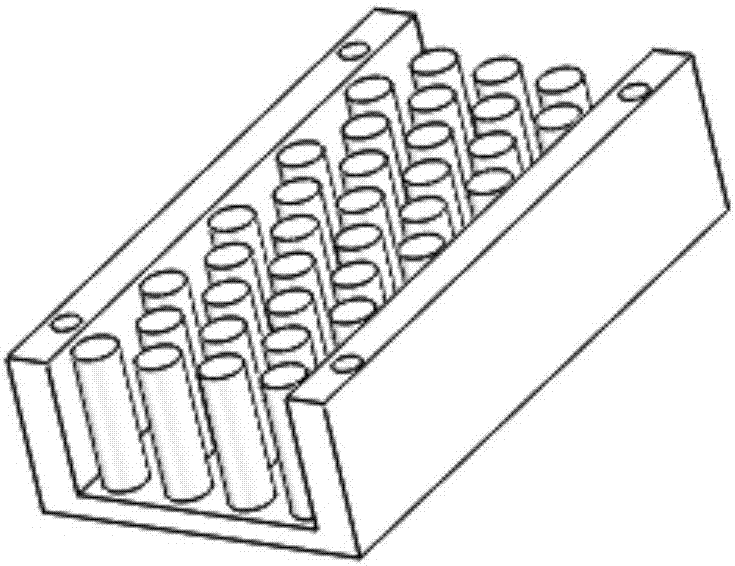

[0022] The technical solution of the present invention is: a Stirling generator with an inserted tube bundle regenerator, including a solar cooker 1, a hot cylinder 2, a cold cylinder 3, a cooling fin 4, a hot cylinder piston 5, and a cold cylinder piston 6 , plug-in tube bundle regenerator 7, hot cylinder connecting rod 8, cold cylinder connecting rod 9, two sleeves 10, crankshaft 11, flywheel 12, drum gear coupling 13 and generator 14; between two cylinders The space is interpenetrated and connected with each other through the tube bundle regenerator 7; the hot cylinder 2 is provided with a hot cylinder piston 5, and the cold cylinder 3 is provided with a cold cylinder piston 6; the sleeve 10 is set on the protrusion of the crankshaft 11, and the two pistons and The sleeves 10 are respectively connected by connecting rods, and the two ends of the connecting rods are hinged with the piston and the sleeve 10; the end of the crankshaft 11 close to the cold cylinder 3 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com