Massage unit and its preparation method and application

A base material, silicone rubber technology, applied in the direction of coating, etc., can solve the problems that the hydrophilic lubricity cannot be maintained, the hydrophilic lubricating coating is easy to fall off, and the grafting effect is not ideal, so as to inhibit the adhesion of bacteria, good Hydrophilic lubricity, effect of relieving and treating asthenopia or dry eye

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0079] In an optional embodiment, the preparation method of the hydrophilic lubricating coating includes the following steps:

[0080] (a) Soak the autoclaved matrix material in an acetone solution containing photosensitizer for pretreatment;

[0081] (b) Put the pretreated matrix material into a reactor containing a mixed solution of OP-10 and PEG1000. The reactor is airtight and nitrogen gas is introduced. The graft is irradiated with ultraviolet light for 25min~55min. Form a grafted modified layer;

[0082] (c) Remove the residues of the base material with the grafted modified layer attached to the surface;

[0083] (d) Under the protection of nitrogen, immerse the material obtained in step (c) in a solvent containing a hydrophilic monomer and an initiator, and irradiate it under ultraviolet light for 1 to 8 minutes;

[0084] (e) Immerse the material obtained in step (d) in a solvent containing a crosslinking agent and additives, and perform irradiation crosslinking under ultraviole...

Embodiment 1

[0104] A massage unit, which is mainly prepared from a base material, and the base material is mainly prepared by mixing silicone rubber A component and silicone rubber B component with a mass ratio of 1:1;

[0105] The surface of the base material has a hydrophilic lubricating coating. The hydrophilic lubricating coating includes a grafted modified layer and a hydrophilic lubricating layer. The grafted modified layer is provided on the outer surface of the base material, and the hydrophilic lubricating layer is provided on the grafted surface. The outer surface of the modified layer; the grafted modified layer and the hydrophilic lubricating layer form an interpenetrating cross-linked network.

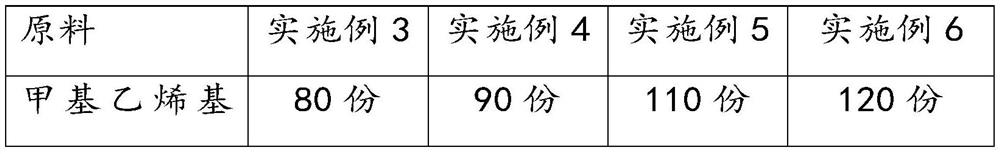

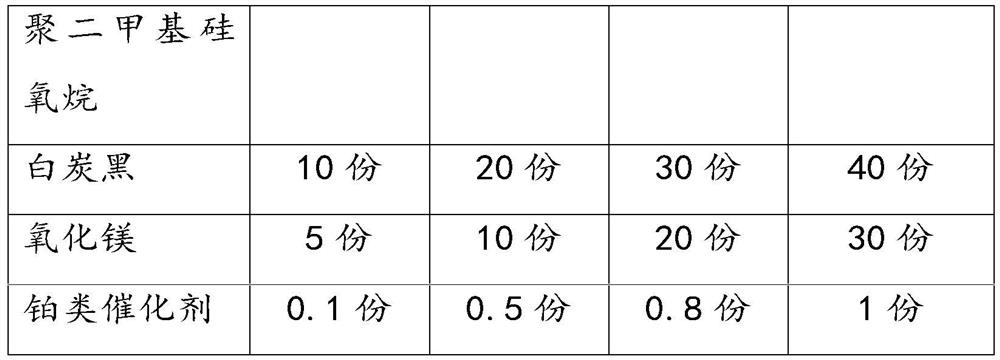

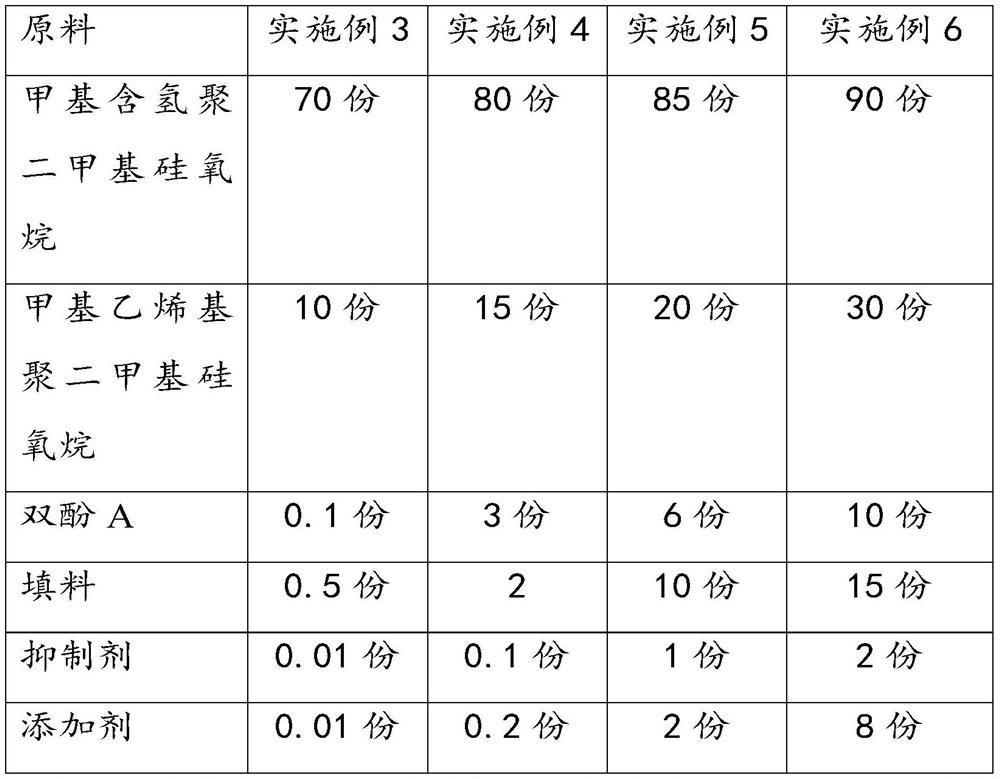

[0106] Among them, the silicone rubber component A is mainly prepared from the following mass parts of raw materials:

[0107] 100 parts of methyl vinyl polydimethylsiloxane, 25 parts of white carbon black, 20 parts of magnesium oxide and 0.5 part of olefin complex of chloroplatinic acid;

[...

Embodiment 2

[0111] A massage unit. The difference from Embodiment 1 is that the base material is mainly prepared by mixing silicone rubber A component and silicone rubber B component with a mass ratio of 1:2, and the rest are the same as Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com