Glass fiber reinforcement PP material with low VOC and preparation method of glass fiber reinforcement PP material

A glass fiber and raw material technology, which is applied in the field of glass fiber reinforced PP material and its preparation, can solve the problems of complex process, damage to the nervous system, immune system and endocrine system, and high equipment requirements, and achieves the effect of less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

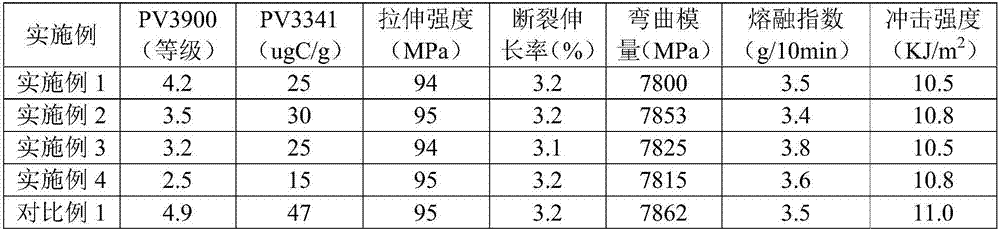

Embodiment 1

[0033] In parts by weight, 58.5 parts of PP, 1.5 parts of extractant masterbatch, 5 parts of grafting agent, and 0.3 parts of antioxidant were sequentially added to the high-speed mixer, mixed at a speed of 200r / min for 0.25h, and Put the mixed materials into the twin-screw extruder, add 40 parts of glass fiber at the No. 3 side feed port, control the screw speed to 450r / min, and control the extrusion temperature: the first zone is 100°C, the second zone 120°C, the temperature of the third to eleventh zones is 230°C, the pressure of the vacuum pump used in the extrusion of the extruder is >0.08Mpa, and the extruded material is pelletized, sieved, and dried to prepare low-VOC glass Fiber reinforced PP material.

Embodiment 2

[0035] In parts by weight, 60 parts of PP, 2.5 parts of extractant masterbatch, 6 parts of grafting agent, and 0.3 parts of antioxidant are sequentially added to the high-speed mixer, mixed at a speed of 250r / min for 0.25h, and Put the mixed material into the twin-screw extruder, add 30 parts of glass fiber at the No. 3 side feed port, control the screw speed to 500r / min, and control the extrusion temperature: the first zone is 110°C, the second zone 120°C, the temperature of the third to eleventh zones is 230°C, the pressure of the vacuum pump used in the extrusion of the extruder is >0.08Mpa, and the extruded material is pelletized, sieved, and dried to prepare low-VOC glass Fiber reinforced PP material.

Embodiment 3

[0037] In parts by weight, 70 parts of PP, 3.5 parts of extractant masterbatch, 8 parts of grafting agent, and 0.4 parts of antioxidant were sequentially added to the high-speed mixer, mixed at a speed of 300r / min for 0.25h, and Put the mixed material into the twin-screw extruder, add 40 parts of glass fiber at the No. 3 side feed port, control the screw speed to 460r / min, and control the extrusion temperature: the first zone is 100°C, the second zone 120°C, the temperature of the third to eleventh zones is 230°C, the pressure of the vacuum pump used in the extrusion of the extruder is >0.08Mpa, and the extruded material is pelletized, sieved, and dried to prepare low-VOC glass Fiber reinforced PP material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com