Comfortable fire resistant fiber and preparation method thereof

A flame retardant fiber and comfort technology, applied in the field of comfort flame retardant fiber and its preparation, can solve the problems of high cost, large addition amount of intrinsic flame retardant fiber, complicated process, etc., and achieves good flame retardant performance, reduced content, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

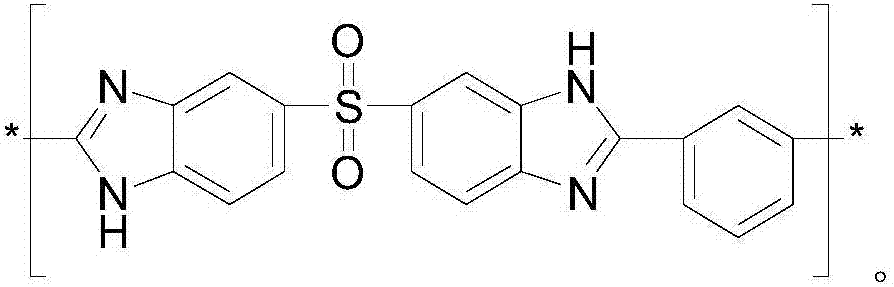

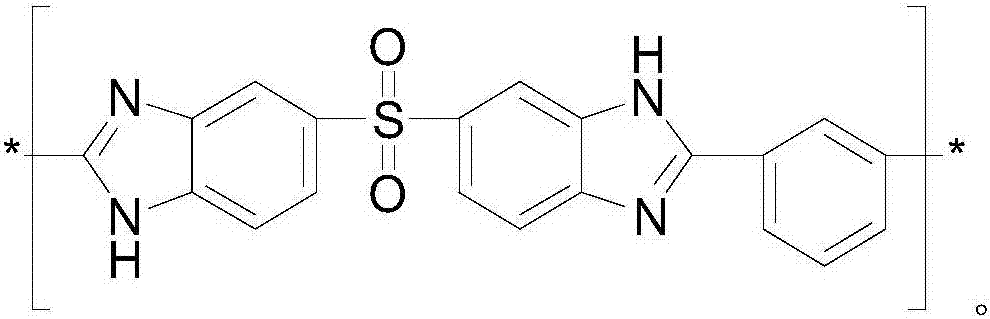

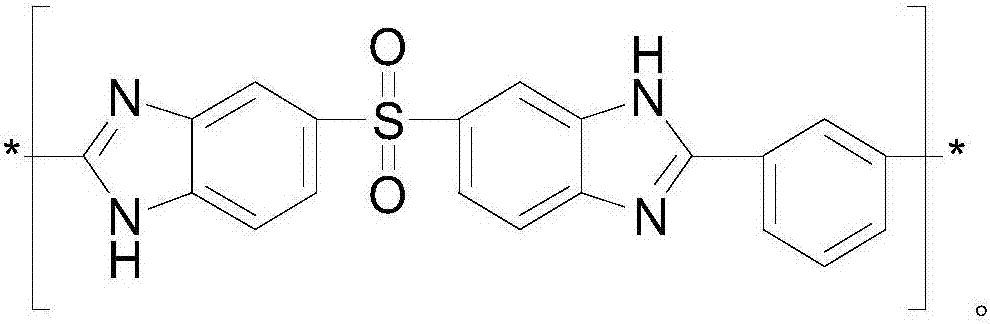

Image

Examples

Embodiment 1

[0030] A comfortable flame-retardant fiber and a preparation method thereof, comprising cellulose with a degree of polymerization of 200 and polym-phenylene isophthalamide with an inherent viscosity of 1.5 dL / g at a mass ratio of 82:18 Proportional mixing, stirring in a 50% aqueous solution of 4-methylmorpholine-N-oxide, and dissolving at 90°C to obtain a spinning solution with a total polymer solid content of 5%, in which cellulose and polyisophthalamide The viscosity ratio of m-phenylenediamine in the solvent is 50. The spinning solution is extruded after being pressurized, and after passing through the air section at 15°C and the coagulation bath (distilled water, 25°C), it is drawn by the first roller, and the nozzle draws The stretching ratio is 6 times, and then enter the drawing bath of 60°C water and the drawing bath of water washing at 90°C respectively, dry at 100°C, and heat-set to obtain a comfortable flame-retardant fiber.

[0031] The test results show that the m...

Embodiment 2

[0036] A comfortable flame-retardant fiber and a preparation method thereof, comprising cellulose with a degree of polymerization of 900 and polym-phenylene isophthalamide with an inherent viscosity of 2.0 dL / g at a mass ratio of 85:15 Proportionally mixed, stirred in 1-butyl-3-methylimidazolium chloride salt, dissolved at 85°C to obtain a spinning solution with a total polymer solid content of 10%, in which cellulose and polyisophthalamide The viscosity ratio of diamine in the solvent is 110. The spinning solution is extruded after pressurization, and after passing through the air section at 15°C and the coagulation bath (distilled water, 25°C), it is drawn by the first roll, where the stretching ratio of the nozzle is 8 times, and then enter the drawing bath of 60°C water and the drawing bath of water washing at 90°C respectively, dry at 100°C, and heat-set to obtain a comfortable flame-retardant fiber.

[0037] The test results show that the monofilament fineness of the com...

Embodiment 3

[0042] A comfortable flame-retardant fiber and a preparation method thereof, comprising cellulose with a degree of polymerization of 1600 and polym-phenylene isophthalamide with an inherent viscosity of 2.5 dL / g at a mass ratio of 88:12 Proportionally mixed, stirred in 1-butyl-3-methylimidazolium bromide, dissolved at 80°C to obtain a spinning solution with a total polymer solid content of 15%, in which cellulose and polyisophthalamide The viscosity ratio of diamine in the solvent is 230. The spinning solution is extruded after pressurization, and after passing through the air section at 15°C and the coagulation bath (distilled water, 25°C), it is drawn by the first roll, where the stretching ratio of the nozzle is 15 times, and then enter the drawing bath of 60°C water and the drawing bath of water washing at 90°C respectively, dry at 100°C, and heat-set to obtain a comfortable flame-retardant fiber.

[0043] The test results show that the single filament fineness of the fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com