Gyro-distributed chamber method for underwater rock plug blasting

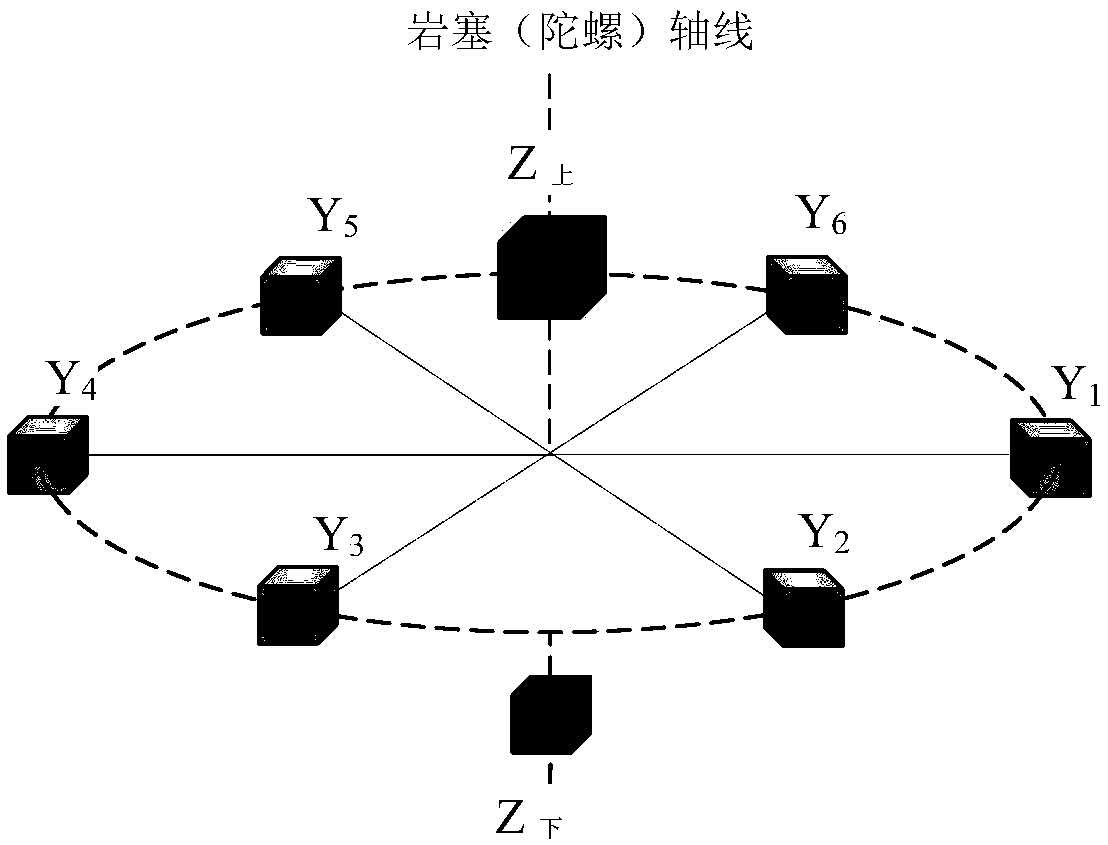

A distributed and gyroscopic technology, applied in blasting and other directions, can solve problems such as obvious clamping effect, large blasting vibration, and residual opening shape of rock plug body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0198] (1) Project overview

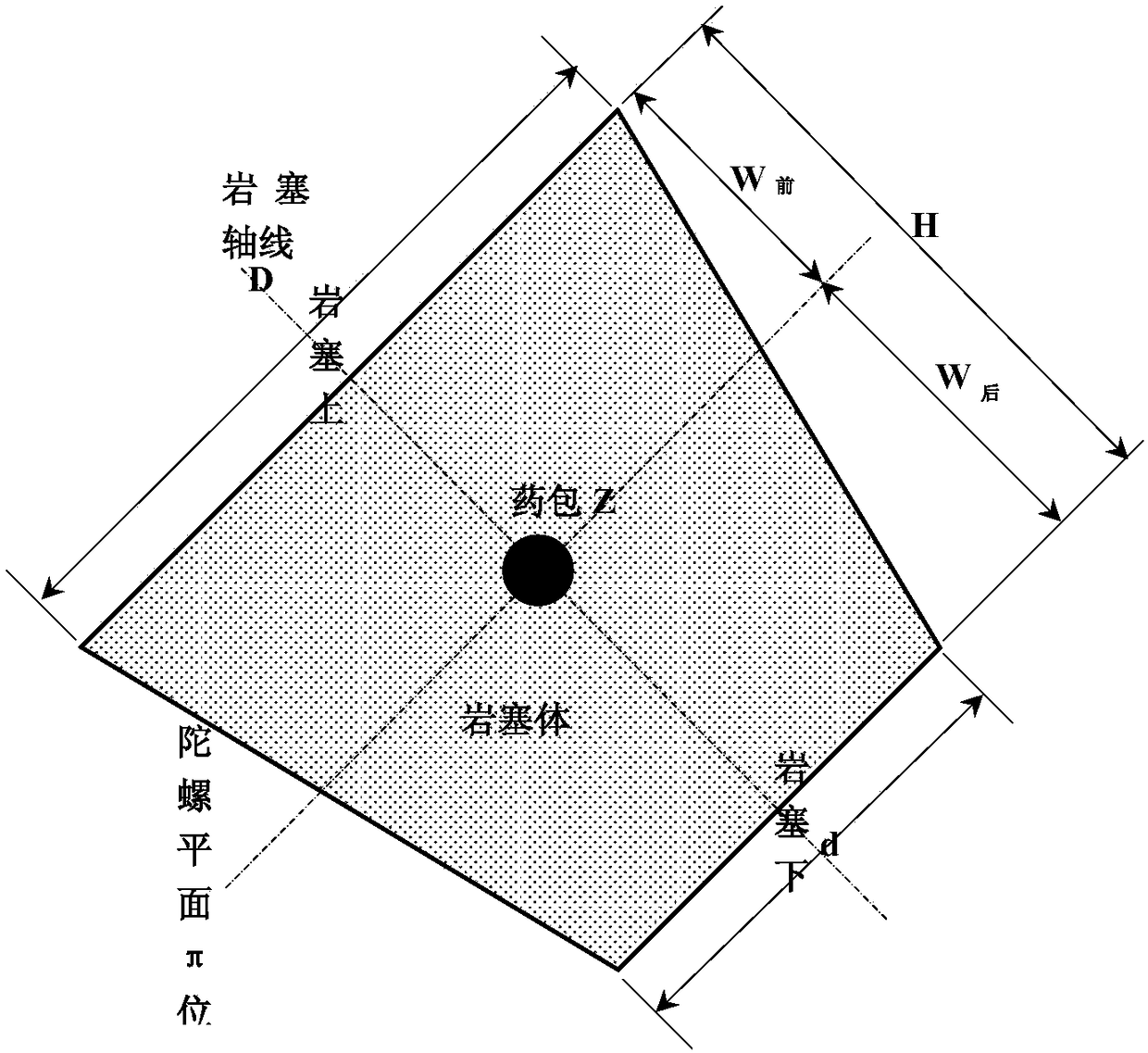

[0199] The sand discharge tunnel and expansion project of the Taohe Estuary in the Liujiaxia of the Yellow River, the water inlet adopts the underwater rock plug blasting technology, and the designed rock plug body is similar to an inverted truncated cone, the angle between the axis and the horizontal plane is 45°, and the angle between the busbar and the axis is 15° horn. The upper opening of the rock plug is elliptical, with a size of 21.60m×20.98m, the lower opening is circular, with a diameter of 10m, and the thickness of the rock plug is 12.30m.

[0200] The rock at the rock plug is mica-quartz schist, mainly weakly weathered rock, with a small amount of slightly weathered rock. The thickness of the weakly weathered rock is 2.0-6.0m, and the rock strength is relatively high. Saturation density 2820kg / m 3 , is hard rock, the rock is relatively complete, and belongs to type II rock (classified by 16, equivalent to 10).

[0201] The explosive...

example 2

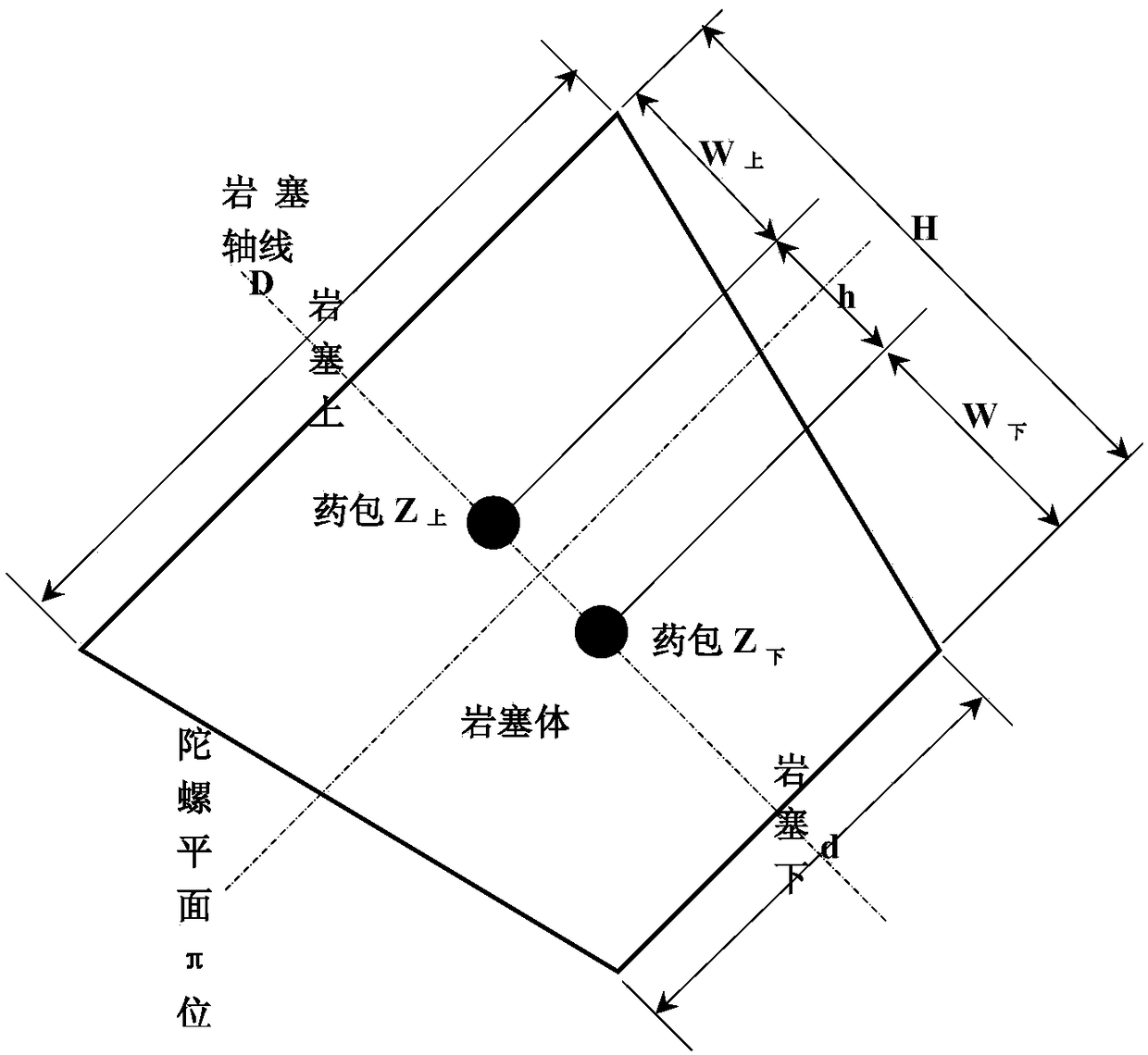

[0267] (1) Project overview

[0268] A project field test shows that the rock mass slope at the entrance section is steep, the slope is generally 75°-85°, and reverse slopes are formed locally. The rock quality of the surrounding rock at the entrance section is hard, the rock is weak to slightly weathered, the surface rock integrity is poor, the average saturated compressive strength of the rock is 118MPa, and the average saturated density of the rock is 2900kg / m 3 , belonging to type II rock (classified according to 16 grades, equivalent to 10 grades), the lower opening of the designed rock plug is circular, the inner diameter is 7m, the outer opening is approximately elliptical, and the size is 11.96m×12.63m; the minimum thickness of the rock plug is 9.8m, and the rock plug The angle between the inlet axis and the horizontal plane is 72°, high-energy emulsion explosive is used, and the density is 1210kg / m 3 ;

[0269] (2) Rock plug pre-splitting hole

[0270] In order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com