A multi-robot intelligent collaborative production system

A production system and multi-robot technology, applied in the field of robotics, can solve problems such as difficult to meet dynamic response and light load, difficult to meet continuous improvement of production efficiency, general flexibility of production adaptability, etc., to achieve good motion/force transmission characteristics, structure Compact, avoiding the effect of turning singularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

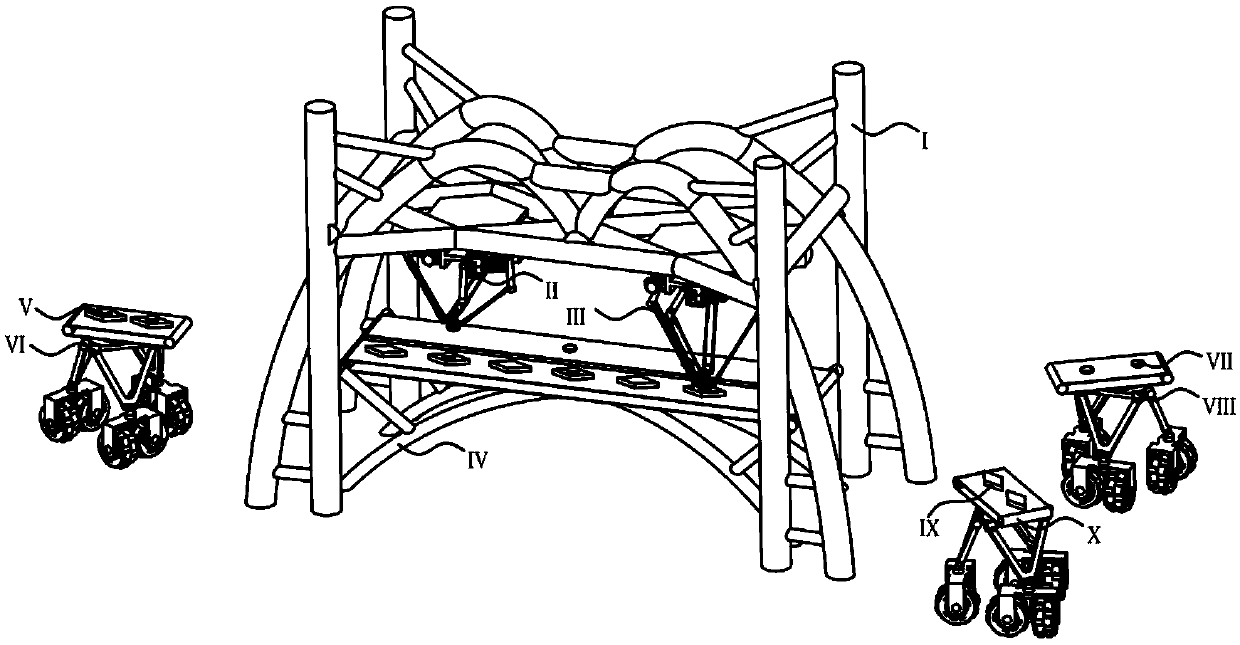

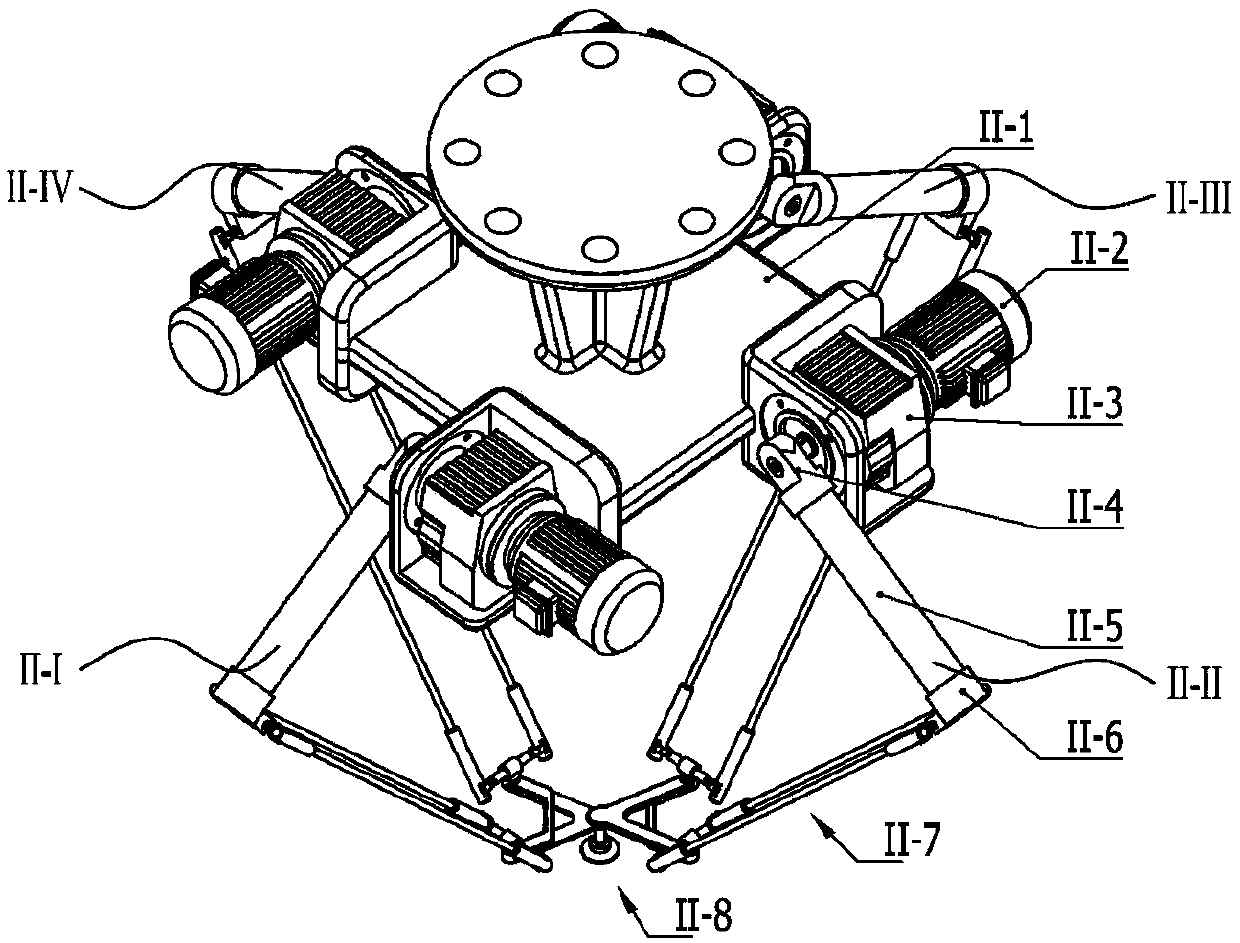

[0025] The structure of a multi-robot intelligent collaborative production system in this embodiment is as follows: figure 1 As shown, it includes a reconfigurable rack I, the first high-speed parallel pick-and-place robot II, the second high-speed parallel pick-and-place robot III, the production line transmission part IV, the first pose-adjustable material handling robot VI, and the second pose-adjustable robot Adjustable material handling robot VIII, material handling robot X with adjustable third pose.

[0026] The substructure of a multi-robot intelligent collaborative production system in this embodiment is now described as follows:

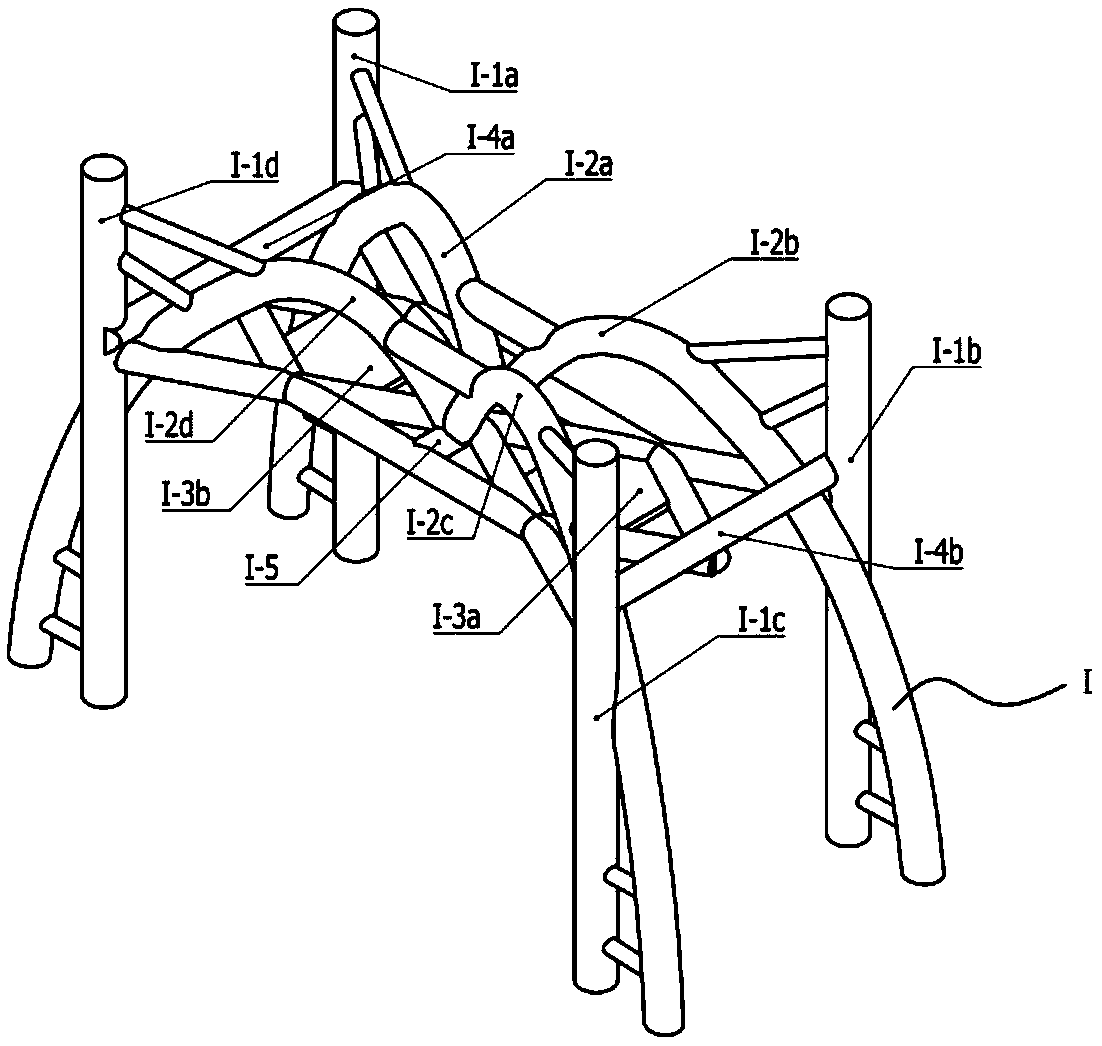

[0027] ① Reconfigurable Rack I

[0028] The structure of the reconfigurable frame I included in the multi-robot intelligent collaborative production system of this embodiment is as follows: figure 2 As shown, the reconfigurable frame I is a truss structure as a whole, including 4 columns (I-1a, I-1b, I-1c, I-1d), 4 arched columns (I-2a, I-...

Embodiment 2

[0046] The structure of a multi-robot intelligent collaborative production system in this embodiment is as follows: Figure 7 As shown, the main difference with Embodiment 1 is that the reconfigurable rack 1 is split into multiple sub-racks I'-1, I'-2 at the connecting rod I-5, and a lifting device is provided at the bottom of each sub-rack. The base of the fixed function (the size and shape of the base should be determined according to the actual situation of the project, the plane of the base in this embodiment is triangular), through the disassembly of the reconfigurable frame I, the first high-speed parallel pick-and-place robot II and the second The second high-speed parallel pick-and-place robot III is divided into two sub-cooperative systems. This enables the two-sub-cooperative system to adapt to longer production lines. And according to the space size and shape of the production line, the sub-cooperation system can be flexibly arranged, for example, on the same side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com