Crystal nucleus type concrete early strength agent and preparation method thereof

A technology of concrete and early strength agent, applied in the preparation of the crystal nucleus type concrete early strength agent, crystal nucleus type concrete early strength agent, concrete early strength agent field, can solve the problem of short demoulding time and no guidance scheme , less loss of concrete strength and other issues, to achieve the effect of short demoulding time, less strength loss in the later period, and less strength loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

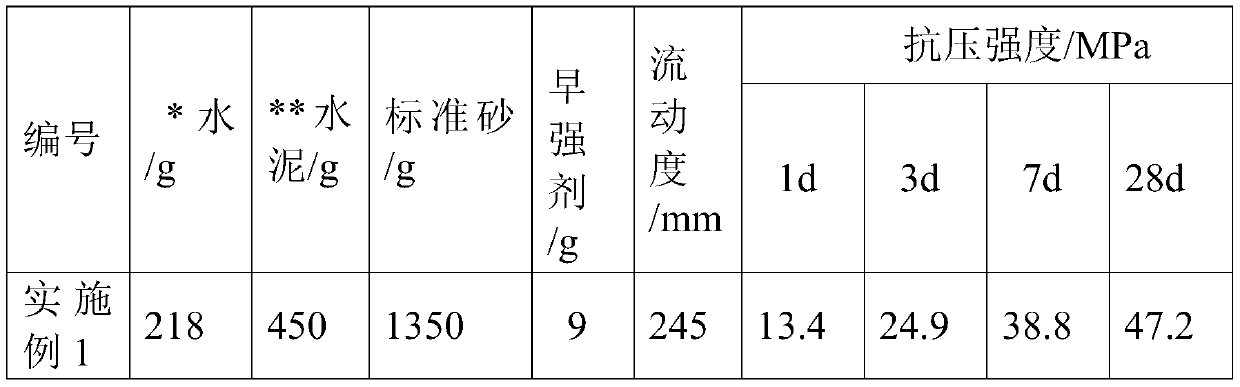

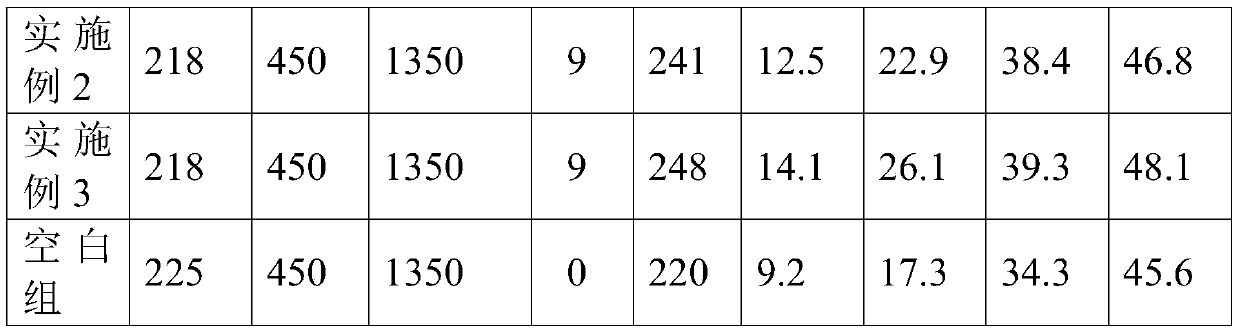

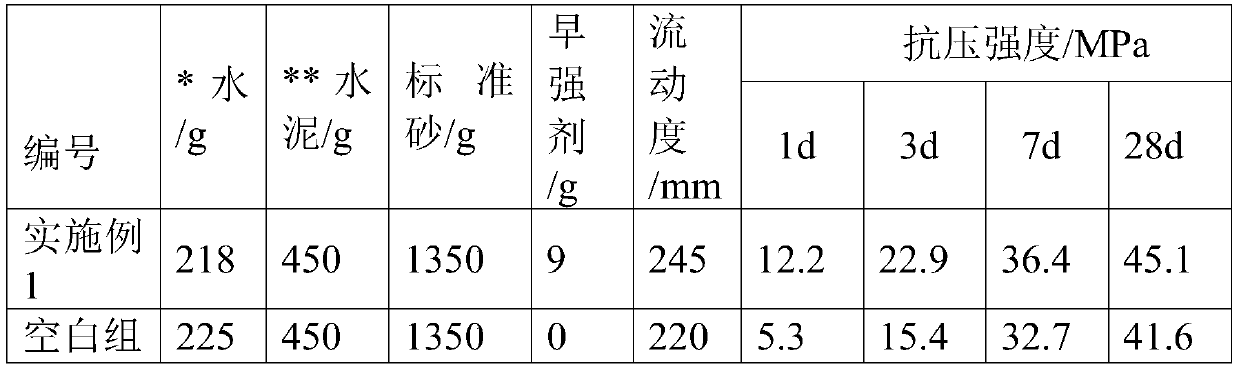

Embodiment 1

[0020]Embodiment 1: the crystal nucleus type concrete early strength agent of the present invention is characterized in that making the described crystal nucleus type concrete early strength agent of 1000 parts by weight is made of the raw materials of the following components and weight ratio Prepared: 130 parts of polymer, 37 parts of sodium metasilicate pentahydrate, 72 parts of calcium nitrate tetrahydrate, and the rest is deionized water. The preparation method of described crystal nucleus type concrete early strength agent comprises the following process steps: 1. first add 130 parts of polymers in the there-necked flask with stirring device, then add deionized water to make up the bottom liquid that the weight becomes 700 parts, and The flask is placed in a hot water bath, the temperature is controlled at 50±0.5°C, the stirring rate is 300-500rpm, and stirred for 0.5h to keep the temperature and concentration of the solution uniform; ②Take 37 parts of sodium metasilicate...

Embodiment 2

[0021] Embodiment 2: the crystal nucleus type concrete early strength agent of the present invention is characterized in that making the described crystal nucleus type concrete early strength agent of 1000 parts by weight is made of the raw materials of the following components and weight ratio Prepared: 110 parts of polymer, 25 parts of sodium metasilicate pentahydrate, 60 parts of calcium nitrate tetrahydrate, and the rest is deionized water. The preparation method of described crystal nucleus type concrete early strength agent comprises the following process steps: 1. first add 110 parts of polymers in the there-necked flask with stirring device, then add deionized water to make up the bottom liquid that the weight becomes 700 parts, and The flask is placed in a hot water bath, the temperature is controlled at 50±0.5°C, the stirring rate is 300-500rpm, and stirred for 0.5h to keep the temperature and concentration of the solution uniform; ②Take 25 parts of sodium metasilicat...

Embodiment 3

[0022] Embodiment 3: the crystal nucleus type concrete early strength agent of the present invention is characterized in that making the described crystal nucleus type concrete early strength agent of 1000 parts by weight is made of the raw materials of the following components and weight ratio Prepared: 150 parts of polymer, 50 parts of sodium metasilicate pentahydrate, 90 parts of calcium nitrate tetrahydrate, and the rest is deionized water. The preparation method of described crystal nucleus type concrete early strength agent comprises the following process steps: 1. first add 150 parts of polymers in the there-necked flask with stirring device, then add deionized water to make up the bottom liquid that the weight becomes 700 parts, and The flask is placed in a hot water bath, the temperature is controlled at 50±0.5°C, the stirring rate is 300-500rpm, and stirred for 0.5h to keep the temperature and concentration of the solution uniform; ②Take 50 parts of sodium metasilicat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com