Halogen-free flame-retardant epoxy curing agent and preparation method thereof

An epoxy curing agent, solid technology, applied in the field of halogen-free flame retardant epoxy curing agent and its preparation, can solve the problems of increasing the risk of epoxy resin use, reducing the flame retardant efficiency, secondary damage, etc., and achieving good resistance. The effect of combustion effect, less side reaction and moderate reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

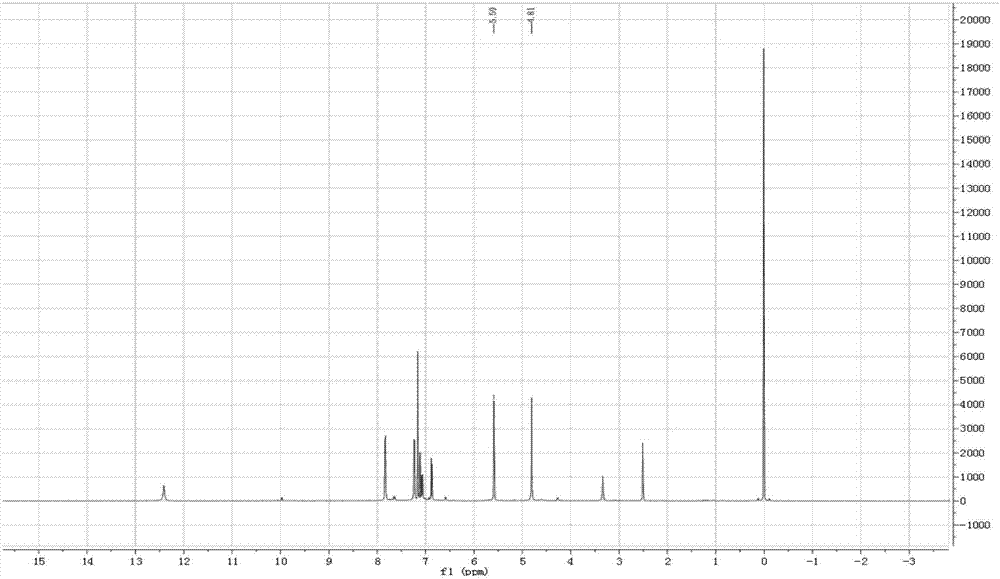

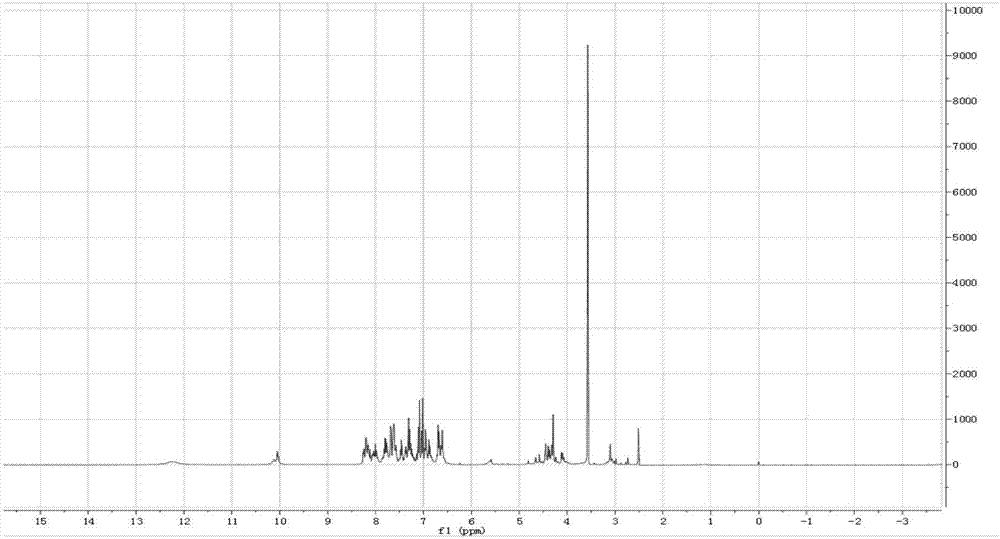

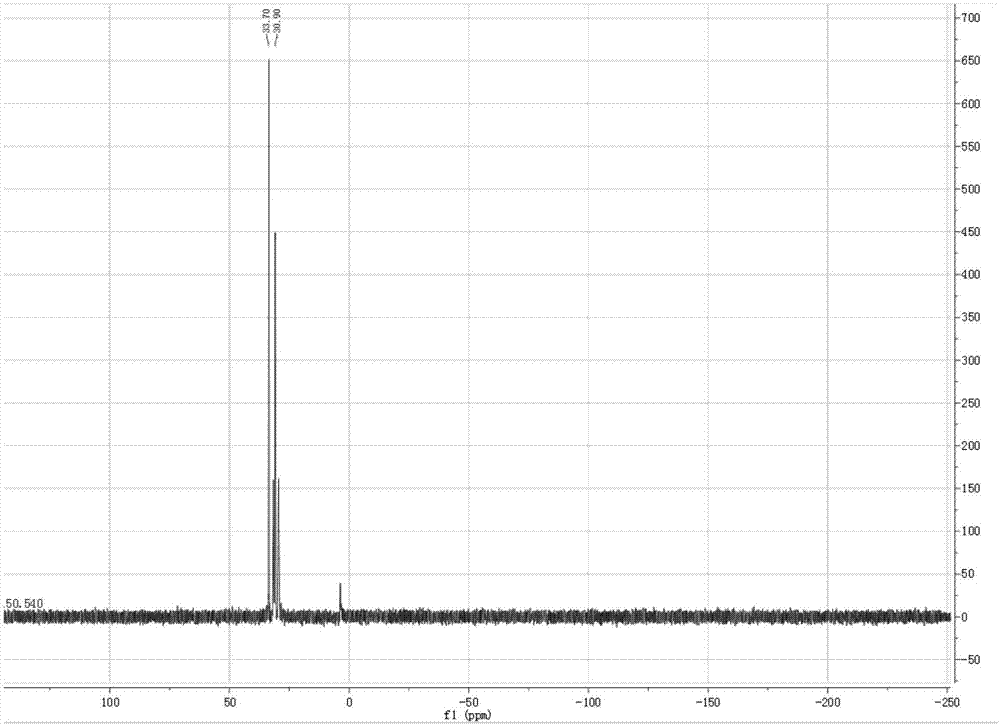

[0027] 1) Preparation of HPM

[0028] Get 49g of maleic anhydride and place it in a three-necked flask, add 20ml of acetone solution. Add the ice-water mixture in the magnetic sub-stirrer, after the maleic anhydride gradually dissolves, add 54.5g of para-aminophenol (addition process, control the amount and time interval each time in small amounts for several times). A yellow suspension was obtained as the reaction proceeded. Filter under reduced pressure and dry in an oven. The product from the previous step was placed in a three-necked flask, added into a mixed solvent of toluene and DMF, and 86 g of p-toluenesulfonic acid was added as a catalyst. Adjust the temperature of the magnetic stirrer to 110°C and continue the reaction for 8h to obtain a red solution. Connected to a vacuum suction filtration device, suction filtration at 130°C for 30 minutes, after removing part of the solvent, the product was placed in deionized water, and left to cool to obtain a large amount o...

Embodiment 2

[0040] Embodiment 2: Determination of curing process without adding accelerator

[0041] The epoxy resin that gets 100g gained is placed in the beaker, and the oil bath temperature setting is 80 ℃. After the epoxy resin viscosity is very small, add the modified product prepared by 35g example 1). Stir well, pour into the mold with oxygen index, and put it in the oven. Pre-cure at 110°C for 1 hour, and cure at 130°C for 1 hour. At this time, check the solidification of the casting solution. Under these conditions, the compound system is still liquid, and the curing effect is very poor.

Embodiment 3

[0042] Embodiment 3: Determination of oxygen index of cured product without adding accelerator

[0043] The epoxy resin that gets 100g gained is placed in the beaker, and the oil bath temperature setting is 80 ℃. After the epoxy resin viscosity is very small, add the modified product prepared by 35g example 1). Stir well, pour into the mold with oxygen index, and put it in the oven. Pre-cure at 130°C for 1 hour, cure at 160°C for 2 hours, and post-cure at 180°C for 1 hour. At this time, the solidification of the casting solution was detected, and the solidification was good. The casting body spline of epoxy resin was obtained by demoulding. The cured product sample prepared in step 4 was tested according to the national standard GB / T2406 through the XZT-100A limiting oxygen index meter. The measured LOI is 28.1, which belongs to the flame retardant material. It shows that epoxy can still be cured at higher temperature without adding accelerator, and the addition of accele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com