Low-melting-point binary nitric acid mixed molten salt nanofluid

A technology of mixing molten salt and nanofluid, which is applied in the field of physical heat transfer and energy storage in high-tech, can solve the problems of not being suitable for single use, high energy consumption, high melting point, etc., and achieve simplified initial operation procedures, reduced costs, and improved thermal conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

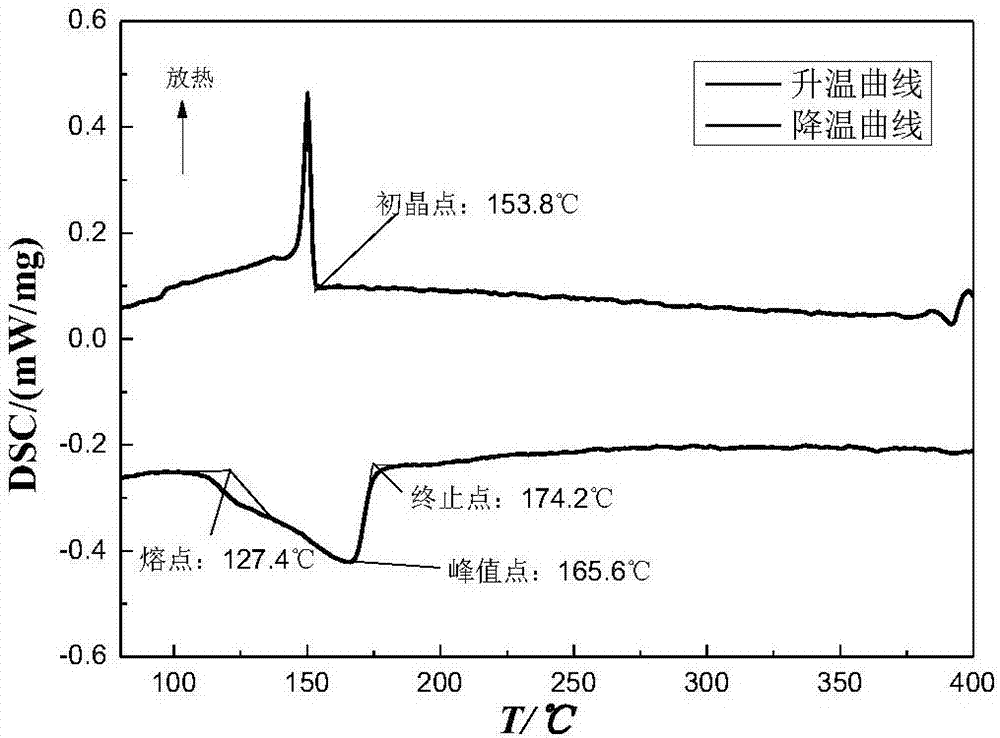

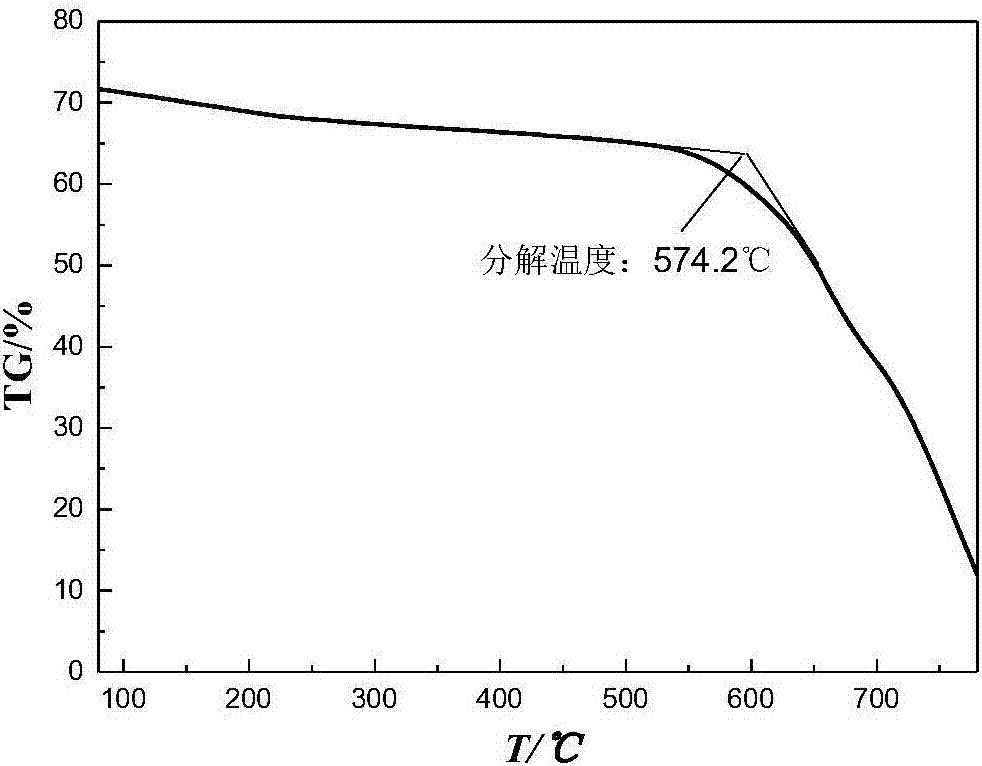

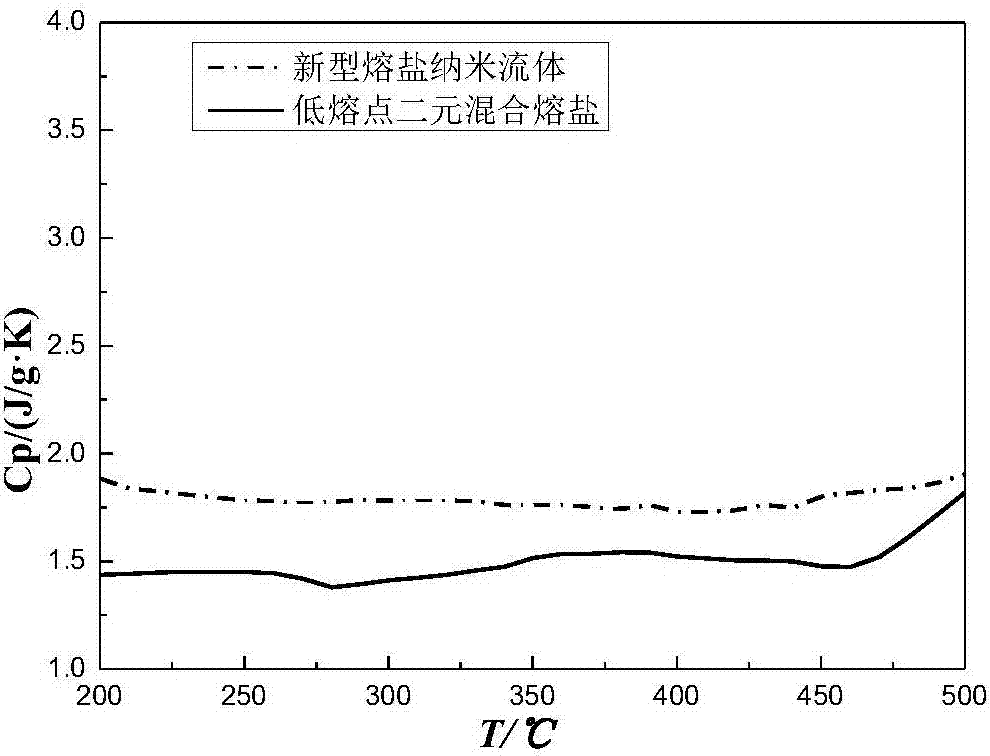

[0032] This novel low melting point binary nitric acid mixed molten salt nanofluid is composed of 99wt% low melting point binary molten salt and 1wt% SiO 2 Nanoparticle composition, wherein the low melting point binary molten salt is composed of 53wt% potassium nitrate and 47wt% calcium nitrate, SiO 2The particle size of the nanoparticles is 20nm. DSC (differential scanning calorimetry) was used to test and analyze the melting point of the new low-cost, low-melting molten salt nanofluid, its decomposition temperature was analyzed by TG (thermogravimetry), and its specific heat was analyzed by DIN51007 standard method. The results show that its melting point is 127.4°C and its decomposition temperature is 574.2°C. The specific heat of the low melting point molten salt nanofluid in liquid state is about 1.73-1.91J / (g·K), and its sensible heat storage cost is about 23.23 yuan / (kW h), its average thermal conductivity is about 0.664W / (m K), and its density is 1.834~2.047g / cm 3 C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com