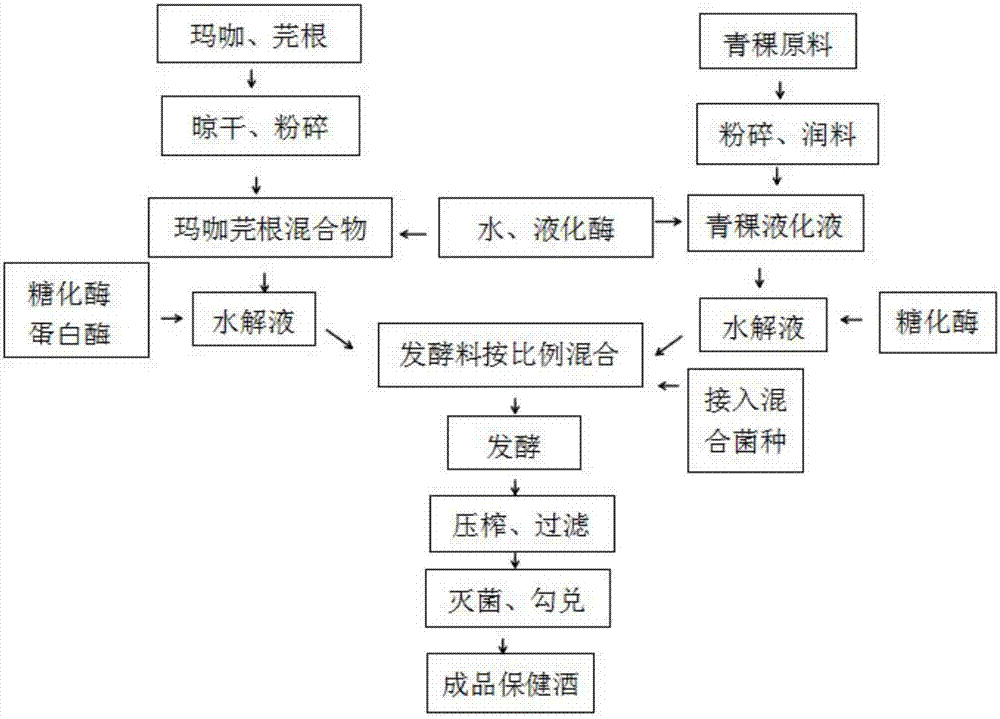

Method for manufacturing health wine by joint fermentation of Tibet special resources and highland barley

A technology of health-care wine and highland barley, which is applied in the field of wine making, can solve the problems of not being able to fully utilize the nutritional content of maca, long-term raw material utilization, and increased production costs, so as to achieve improved raw material utilization, high nutritional and health care value, and economical cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1: Grind 15kg of maca and 20kg of coriander root into powder, add 4 times the mass of water, stir evenly, adjust the temperature of the mixture to 65°C, stir for 30min until the mixture absorbs water and expand, heat to the gelatinization temperature of the mixture, Hold for 30 minutes; adjust the temperature of the maca and coriander root mixture after starch gelatinization to 95°C and maintain it for 60 minutes, adjust the pH to 5.5 with alkali / acid solution, add α-amylase 90U / g, and continue stirring Extract by enzymatic hydrolysis, then lower the temperature to 58°C, add 120 U / g of glucoamylase, and perform enzymatic hydrolysis for 90 minutes to obtain maca coriander root saccharification liquid; Adjust to 50°C, add protease 60U / g, and continue stirring for 30 minutes to facilitate the action of protease.

[0032] Step 2, add a certain quality of water to 100kg of highland barley powder to moisten the material, the ratio of material to water is 1:3.0, and stir ...

Embodiment 2

[0038] Step 1: Grind 20kg of maca and 15kg of coriander root into powder, add 4.5 times the mass of water, stir evenly, adjust the temperature of the mixture to 60°C, stir for 30 minutes until the mixture absorbs water and expand, and heat to the gelatinization temperature of the mixture. Hold for 30 minutes; adjust the temperature of the maca and coriander root mixture after starch gelatinization to 100°C and maintain it for 40 minutes, adjust the pH to 5.5 with alkali / acid solution, add α-amylase 100U / g, and continue stirring Enzymolysis and extraction, then lower the temperature to 60°C, add glucoamylase 120U / g, and enzymatically hydrolyze for 60 minutes to obtain maca coriander root saccharification liquid; Adjust to 52°C, add 80 U / g of protease, and continue to stir for 30 minutes to facilitate the action of protease.

[0039] Step 2, add a certain quality of water to 100kg of highland barley powder to moisten the material, the ratio of material to water is 1:2.8, and sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com