Preparation method and applications of biological inorganic hybrid membrane based on immobilized laccase adopting copper foil carrier

A copper foil carrier and hybrid membrane technology, which is applied in biochemical equipment and methods, chemical instruments and methods, fixed on or in inorganic carriers, etc., can solve the problem of insufficient structural stability, low laccase loading, and leakage. Many problems, to achieve the effect of low cost, enhanced laccase activity, and improved use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

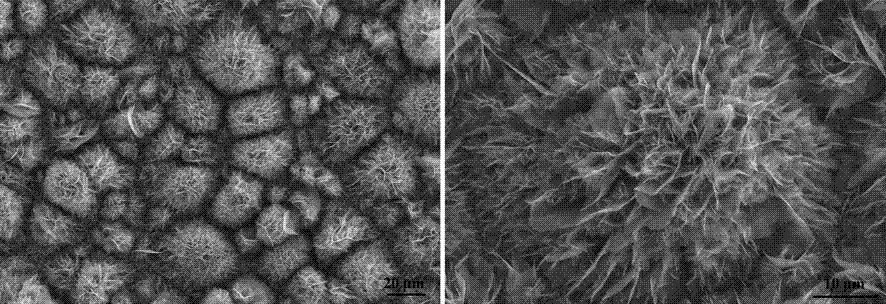

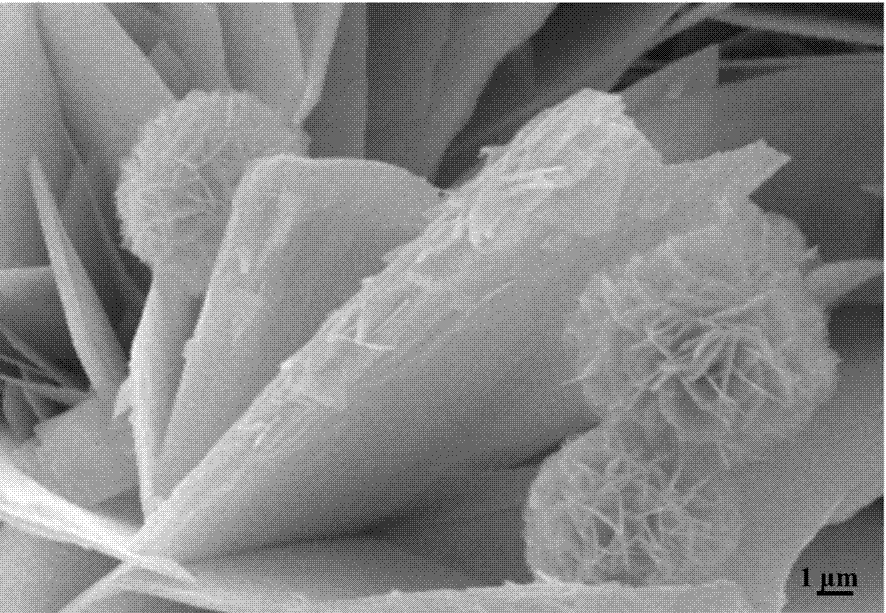

[0025] a) Copper foil carrier preparation: Cut the copper foil (thickness 0.1 mm) into blocks with a length and width of 30 mm and 20 mm respectively, clean it with 2 mol / L HCl under ultrasonic for 15 min, and then wash it with deionized water and ethanol Each was cleaned for 3 min; then the treated copper foil was soaked in 2 mL of (NH 4 ) 2 S 2 o 8 (0.1 mol / L) and Na 2 HPO 4 (0.4 mol / L) in 20 mL of aqueous solution for 1 h, removed, washed with deionized water, and dried at 40 °C for 2 h under nitrogen protection to prepare the immobilized laccase carrier.

[0026] b) Fixation of laccase: prepare 20 mL of laccase solution with a concentration of 0.1 mg / mL in phosphate buffer solution (0.005 mol / L, pH 5), and stir magnetically at room temperature for 6 min; The prepared carrier was soaked in the above laccase solution for 6 h, the surface of the carrier was washed with deionized water without immobilized laccase, and the hybrid enzyme finished film was obtained by vacuum...

Embodiment 2

[0029] a) Copper foil carrier preparation: Cut the copper foil (thickness 0.1 mm) into blocks with a length and a width of 30 mm and 20 mm respectively, clean it with 5 mol / L HCl under ultrasonic for 15 min, and then wash it with deionized water and ethanol Each was cleaned for 3 min; then the treated copper foil was soaked in 3 mL of (NH 4 ) 2 S 2 o 8 (0.3 mol / L) and Na 2 HPO 4 (0.6 mol / L) in 20 mL of aqueous solution for 3 h, removed, washed with deionized water, and dried at 40 °C for 2 h under nitrogen protection to prepare the immobilized laccase carrier;

[0030] b) Fixation of laccase: prepare 20 mL of laccase solution with a concentration of 0.2 mg / mL in phosphate buffer solution (0.05 mol / L, pH 6), stir magnetically at room temperature for 7 minutes, and then mix the The prepared carrier was soaked in the above-mentioned laccase solution for 18 h, the surface of the carrier was washed with deionized water without immobilized laccase, and dried in vacuum at 30°C t...

Embodiment 3

[0033] a) Preparation of copper foil carrier: Cut the copper foil (thickness 0.1 mm) into blocks with the length and width of 30 mm and 20 mm respectively, clean them with 6 mol / L HCl under ultrasonic for 15 min, and then wash them with deionized water and ethanol respectively. Wash for 4 min; then soak the treated copper foil in 4.5 mL of (NH 4 ) 2 S 2 o 8 (0.6 mol / L) and Na 2 HPO 4 (0.7 mol / L) in 20 mL of aqueous solution for 5 h, removed, washed with deionized water, and dried at 40 °C for 2 h under nitrogen protection to prepare the immobilized laccase carrier.

[0034] b) Laccase immobilization: Prepare 20 mL of laccase solution with a concentration of 0.4 mg / mL in phosphate buffer solution (0.08 mol / L, pH 6.5), and stir magnetically at room temperature for 8 min; The prepared carrier was soaked in the above laccase solution for 16 h, the surface of the carrier was washed with deionized water without immobilized laccase, and dried in vacuum at 30°C to prepare the fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com