Preprocessing process for bagasse saccharification utilization

A technology for pretreatment and bagasse, applied in the field of solid waste resource utilization, can solve the problems of difficult utilization of biomass energy, high cost, low pretreatment efficiency, etc., and achieves increased specific surface area, low cost, and improved conversion. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

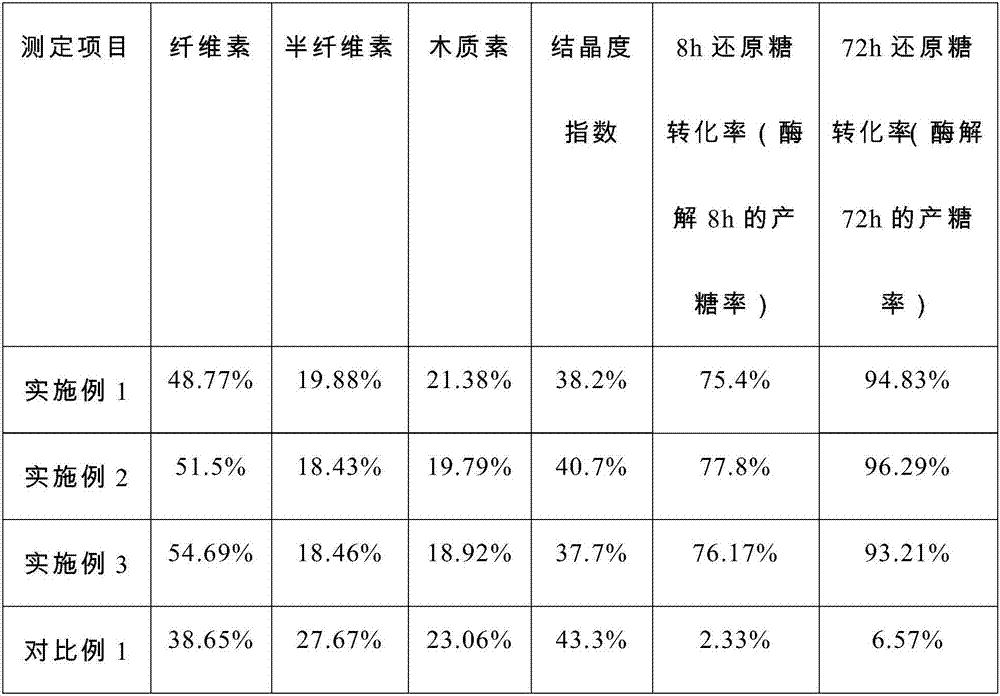

Embodiment 1

[0021] Embodiment 1: bagasse sample after pretreatment

[0022] The pretreatment process of the present embodiment, the steps are:

[0023] Weigh 10.0000±0.0010g bagasse, add 100.0±0.1mL sodium hydroxide solution with a mass concentration of 7w%, stir evenly, transfer to a constant temperature water bath shaker, pretreat at 50°C for 0.5h, and then add 2g urea, and quickly cooled down to -12°C at a rate of -6°C to -12°C / min, pretreated at a constant temperature for 1.5 hours, filtered to remove the filtrate, and washed the filter residue with distilled water until the washing water was neutral, and the filter residue was dried. Bagasse sample after pretreatment.

Embodiment 2

[0024] Embodiment 2: bagasse sample after pretreatment

[0025] The pretreatment process of the present embodiment, the steps are:

[0026] Weigh 10.0000±0.0010g bagasse, add 100.0±0.1mL sodium hydroxide solution with a mass concentration of 7w%, stir evenly, transfer to a constant temperature water bath shaker, pretreat at 50°C for 1h, and then add 2g urea to it , and quickly cooled down to -12°C at a rate of -6°C to -12°C / min, pretreated at a constant temperature for 1 hour, filtered to remove the filtrate, and washed the filter residue with distilled water until the washing water was neutral, and the filter residue was pretreated after drying Bagasse samples after.

Embodiment 3

[0027] Embodiment 3: bagasse sample after pretreatment

[0028] The pretreatment process of the present embodiment, the steps are:

[0029] Weigh 10.0000±0.0010g bagasse, add 100.0±0.1mL sodium hydroxide solution with a mass concentration of 7w%, stir evenly, transfer to a constant temperature water bath shaker, pretreat at 50°C for 1.5h, and then add 2g urea, and quickly cooled down to -12°C at a rate of -6°C to -12°C / min, pretreated at a constant temperature for 0.5h, filtered to remove the filtrate, and washed the filter residue with distilled water until the washing water was neutral, and the filter residue was dried. Bagasse sample after pretreatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com