Photochemical treatment solution and chemical cleaning method for surface pretreatment of aluminum or aluminum alloy

An aluminum alloy surface, chemical cleaning technology, applied in the field of photochemical treatment liquid for aluminum alloy surface pretreatment and chemical cleaning, can solve the problems of unsatisfactory corrosion resistance of the coating layer, low production efficiency, pollution of the environment, etc. Friendly, close to aluminum consumption, low aluminum consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0031] Specific embodiment one: In this embodiment, the components in the photochemical treatment solution for surface pretreatment of aluminum or aluminum alloy and the concentration of each component:

[0032]

[0033] Rhine Chemicals water-based aluminum corrosion inhibitor RC5820 is produced by Aobei Technology (Shanghai) Co., Ltd.

[0034] The alloy surface pretreatment chemical cleaning method of the present embodiment is carried out according to the following steps:

[0035] Step 1. Wipe the surface of aluminum or aluminum alloy with gasoline at a temperature of 50°C and a concentration of 25g / 500ml to remove oil, and dry at 50°C for 15 minutes;

[0036] Step 2. Rinse twice with hot water at a temperature of 50°C, each time for 5 minutes;

[0037] Step 3, then wash with alkali at a temperature of 65°C and a concentration of 25g / 500ml NaOH solution for 15 minutes;

[0038] Step 4, then rinse twice with hot water at a temperature of 30°C, each time for 5 minutes;

...

specific Embodiment approach 2

[0041] Specific embodiment two: In this embodiment, the components in the photochemical treatment solution for surface pretreatment of aluminum or aluminum alloy and the concentration of each component:

[0042]

[0043] In this embodiment, the alloy surface pretreatment chemical cleaning method is operated according to Embodiment 1.

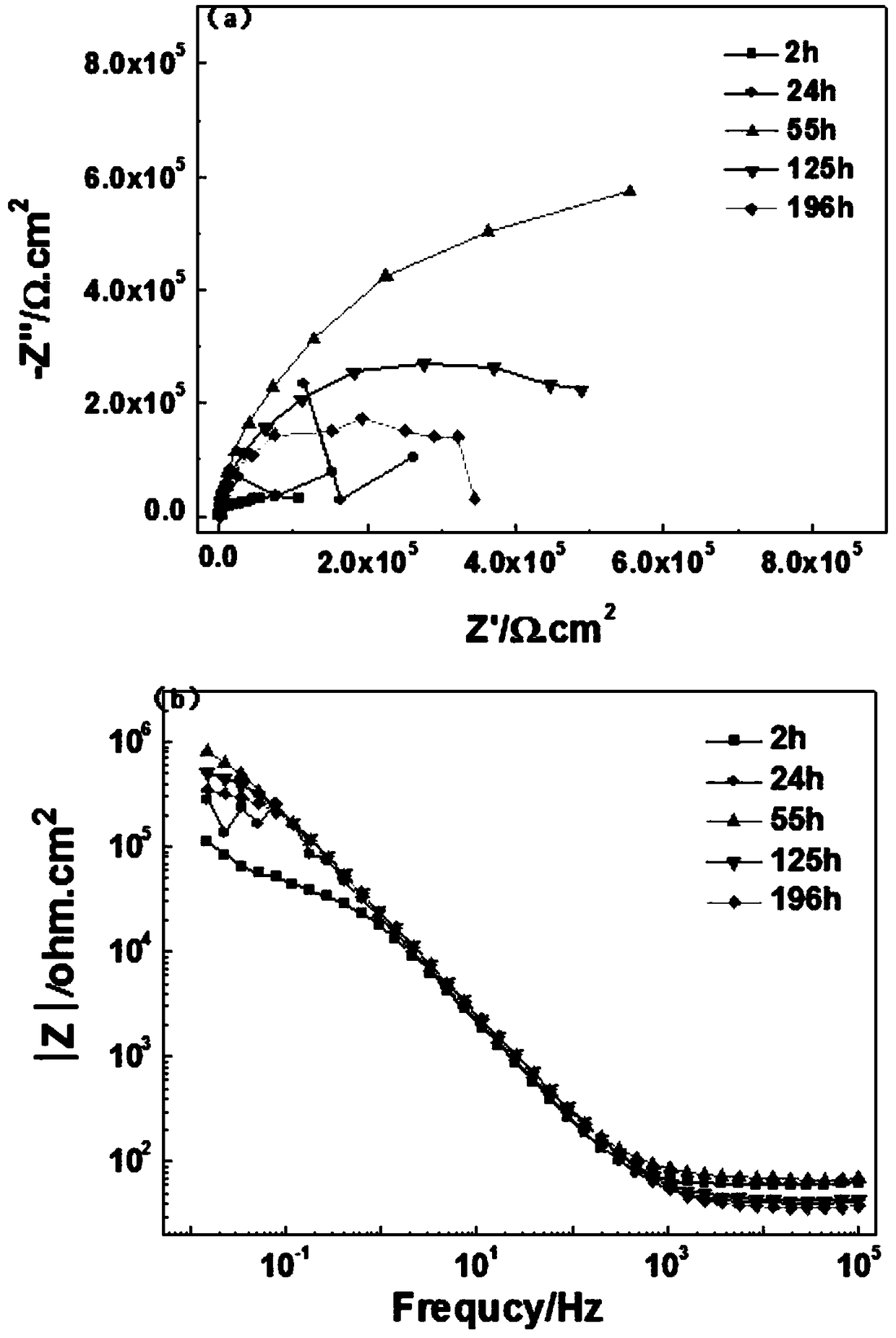

[0044] Adopt following test to verify invention effect

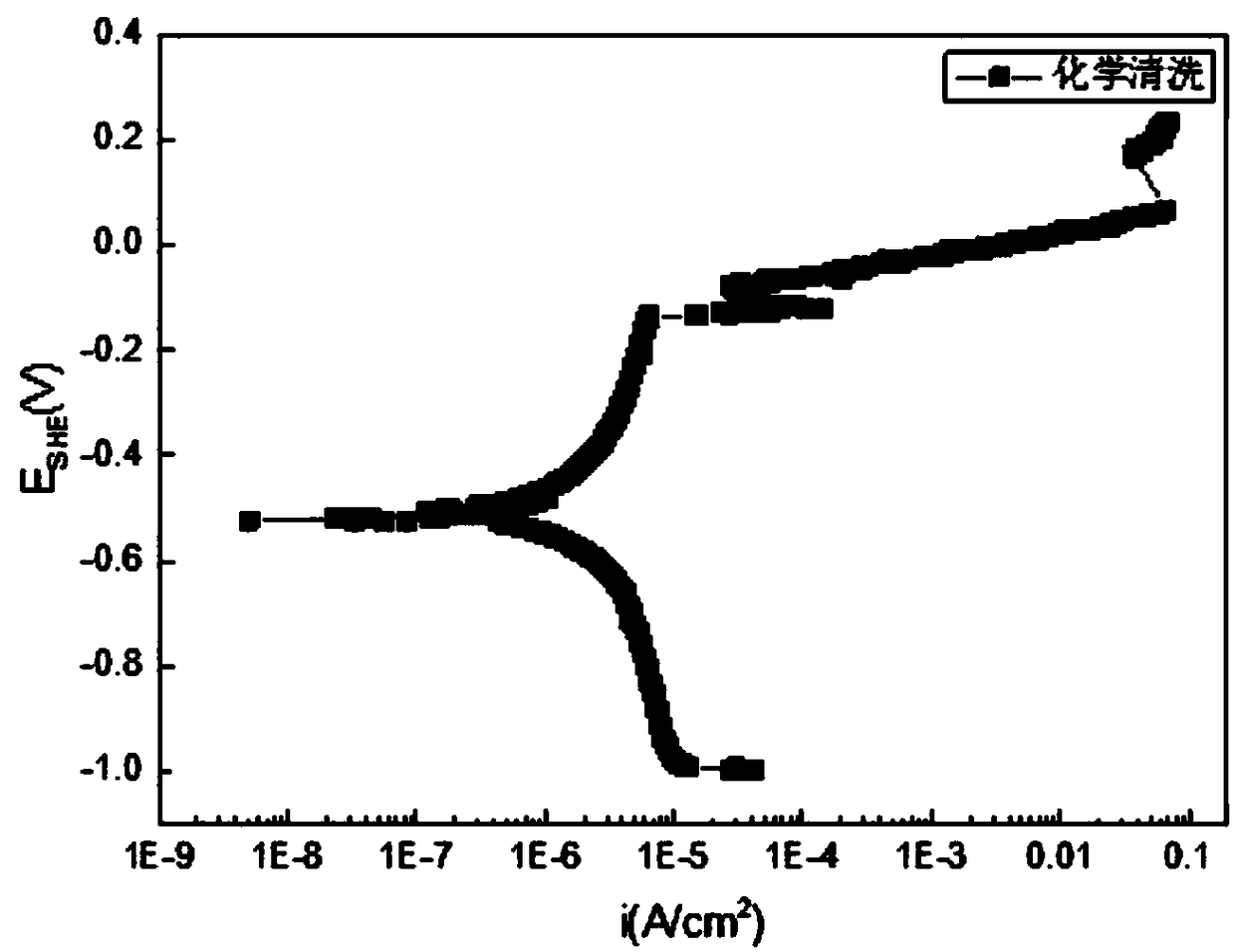

[0045] 1. Potentiodynamic polarization curve test, see the results figure 1

[0046] Using the potentiodynamic polarization curve, we can obtain important parameters such as corrosion potential and corrosion current density (for the case of passivation area, there are also passivation current and passivation interval) by fitting the linear part of the cathode and anode Tafel regions. , and the fitting results are shown in Table 1.

[0047] Table 1 Electrochemical parameters of polarization curves of aluminum alloys

[0048]

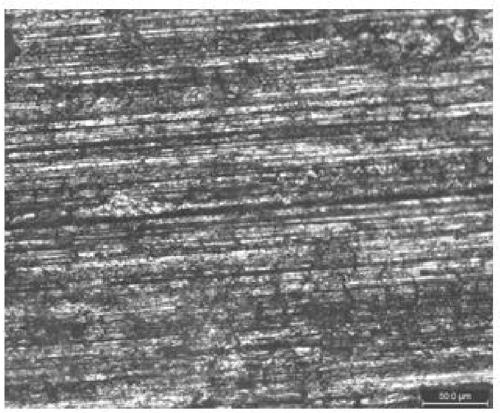

[0049] Second, scanning electron microscope characteriza...

specific Embodiment approach 3

[0057] Specific embodiment three: In this embodiment, the components in the photochemical treatment liquid for surface pretreatment of aluminum or aluminum alloy and the concentration of each component:

[0058]

[0059] In this embodiment, the alloy surface pretreatment chemical cleaning method is operated according to the first specific embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com