Energy-saving drying device for aquatic products

A drying device and aquatic product technology, applied in the direction of drying gas arrangement, progressive dryer, drying solid materials, etc., can solve the problems of great influence on food quality, lack of sterilization facilities, solute loss, etc., to avoid oxidation and Surface yellowing, improved antifouling and high temperature resistance, fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

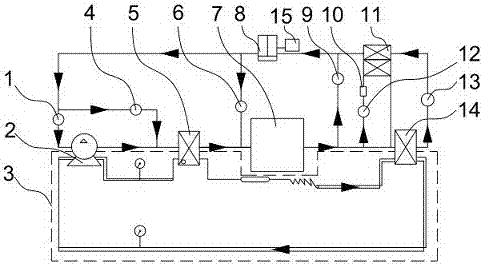

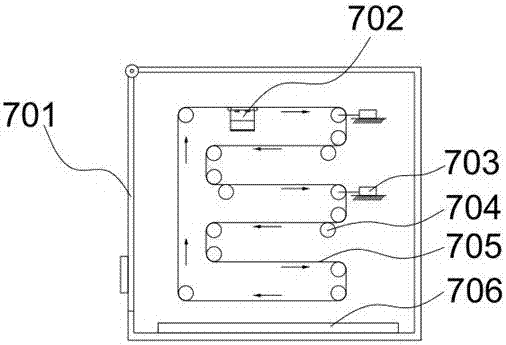

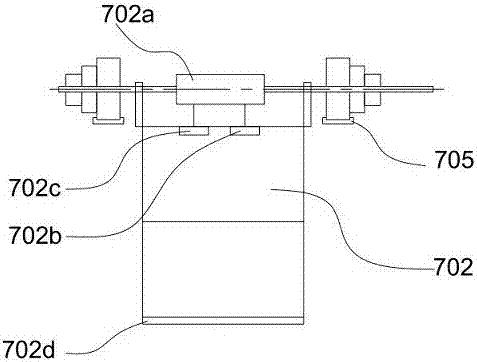

[0018] like Figure 1-3 As shown, an energy-saving drying device for aquatic products includes an air pump 8, a compressor 2 connected to the air pump 8, a drying box 7 connected to the compressor 2, and a heat pump system 3. The left side of the air pump 8 passes through the pipeline in turn The first control valve 1, compressor 2 and condenser 5 are connected, the condenser 5 is connected with the drying box 7, and the right side of the drying box 7 is connected with the evaporator 14, the fifth control valve 13, and the plate heat exchanger in turn through pipelines 11. The plate heat exchanger 11 is connected to the air pump 8, the air pump 8 is also connected to a solar module 15, the solar module 15 is composed of a solar panel and a battery, the heat pump system 3 includes a compressor 2, a condenser 5 and an evaporator 14, The pipeline on one side of the evaporator 14 is provided with a fourth control valve 12 and a blower fan 10, and the pipeline of the third control ...

Embodiment 2

[0021] like Figure 1-3 As shown, an energy-saving drying device for aquatic products includes an air pump 8, a compressor 2 connected to the air pump 8, a drying box 7 connected to the compressor 2, and a heat pump system 3. The left side of the air pump 8 passes through the pipeline in turn The first control valve 1, compressor 2 and condenser 5 are connected, the condenser 5 is connected with the drying box 7, and the right side of the drying box 7 is connected with the evaporator 14, the fifth control valve 13, and the plate heat exchanger in turn through pipelines 11. The plate heat exchanger 11 is connected to the air pump 8, the air pump 8 is also connected to a solar module 15, the solar module 15 is composed of a solar panel and a battery, the heat pump system 3 includes a compressor 2, a condenser 5 and an evaporator 14, The pipeline on one side of the evaporator 14 is provided with a fourth control valve 12 and a blower fan 10, and the pipeline of the third control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com