Overhead tank heat exchange system and modified pitch production system

A heat exchange system and a technology for an asphalt high setting tank, which is applied in the field of asphalt production, can solve the problems of ineffective utilization of asphalt heat, poor molding of modified asphalt products, and high temperature of asphalt discharging, so as to overcome the problems of modified asphalt products. Poor molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

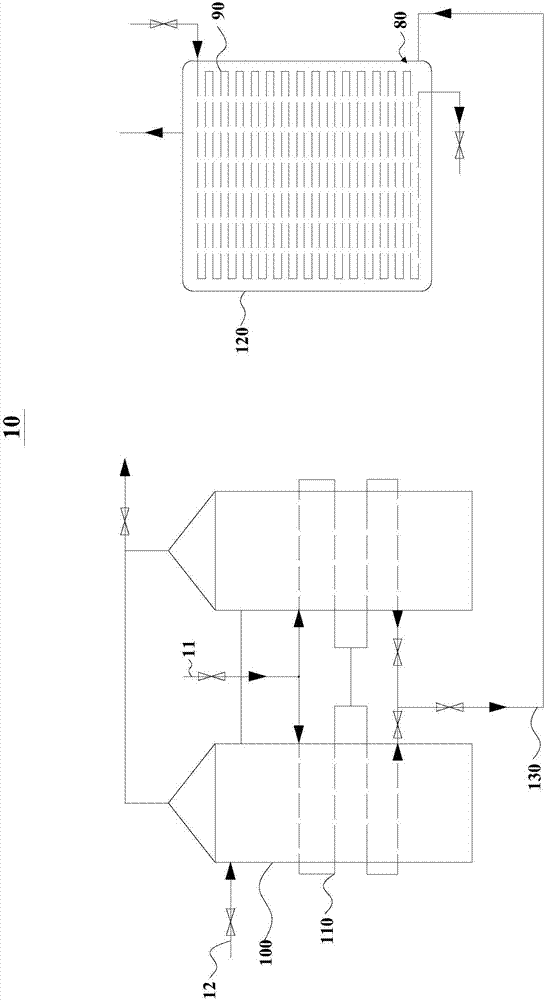

[0046] This embodiment provides a heat exchange system 10 with a high-mounted tank, which aims to solve the existing problem of poor asphalt cooling effect in the high-mounted asphalt tank in the modified asphalt production system.

[0047] Please refer to figure 1 , figure 1 A schematic diagram of the high tank heat exchange system 10 is provided.

[0048] As shown in the figure, the high-set tank heat exchange system 10 includes an asphalt high-set tank 100, a heat conduction device 110, a heat exchanger 120, and a first pipeline 130. In the figure, the modified asphalt delivery pipeline 12 transports the asphalt high-set tank 100 Modified asphalt raw material. The direction of the arrow in the figure is the flow direction of the fluid.

[0049] Wherein, in this embodiment, there are two asphalt elevated tanks 100, and the number may be one, three or more in other implementation manners.

[0050] The heat conduction device 110 is arranged in the high asphalt tank 100, an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap