Multi-wall carbon nanotube/poly L-histidine composite material-modified glassy carbon electrode and preparation method thereof

A technology of multi-walled carbon nanotubes and glassy carbon electrodes, which is applied in the direction of material electrochemical variables, material analysis, and material analysis through electromagnetic means, which can solve the problems of unfavorable electrode surface modification, easy agglomeration, and disadvantages, and achieve enhanced Electrochemical reactivity, good electrical conductivity, and low impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A multi-wall carbon nanotube / poly-L-histidine composite material modified glassy carbon electrode includes a glassy carbon electrode on which poly-L-histidine and multi-wall carbon nanotubes are sequentially deposited on the surface of the glassy carbon electrode.

[0026] A preparation method of the multi-wall carbon nanotube / poly-L-histidine composite material modified glassy carbon electrode, which comprises the following steps:

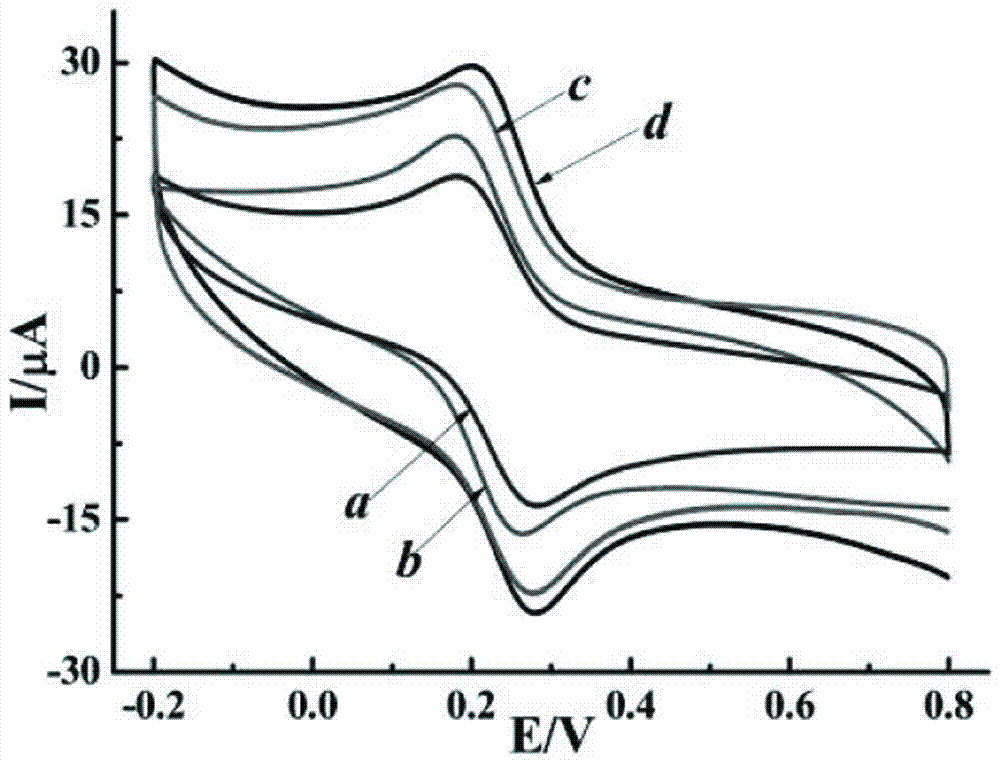

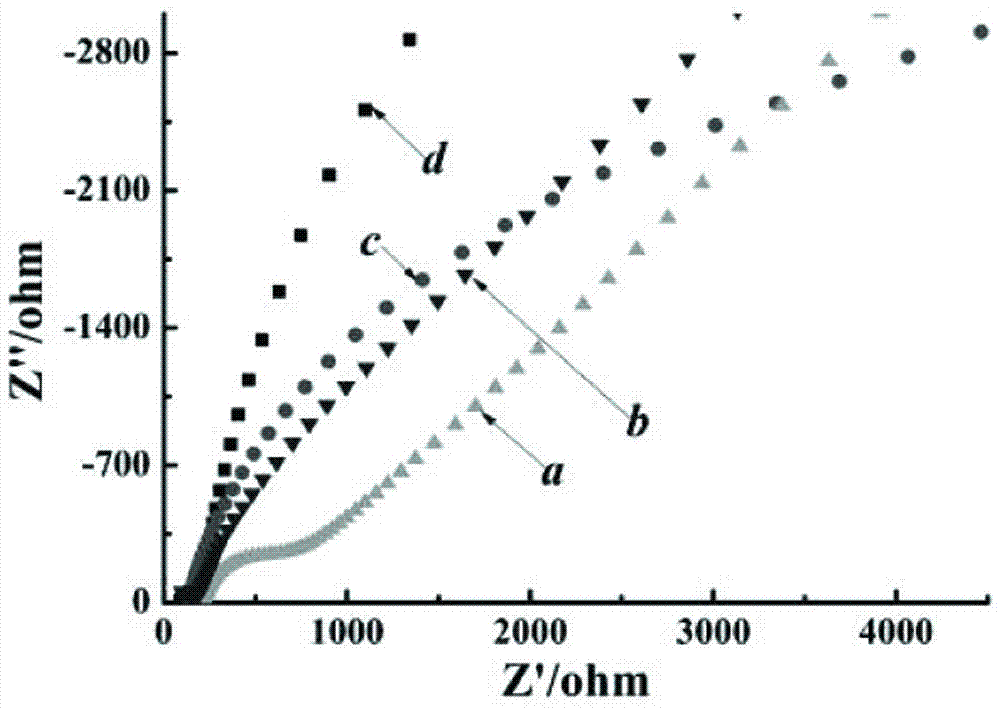

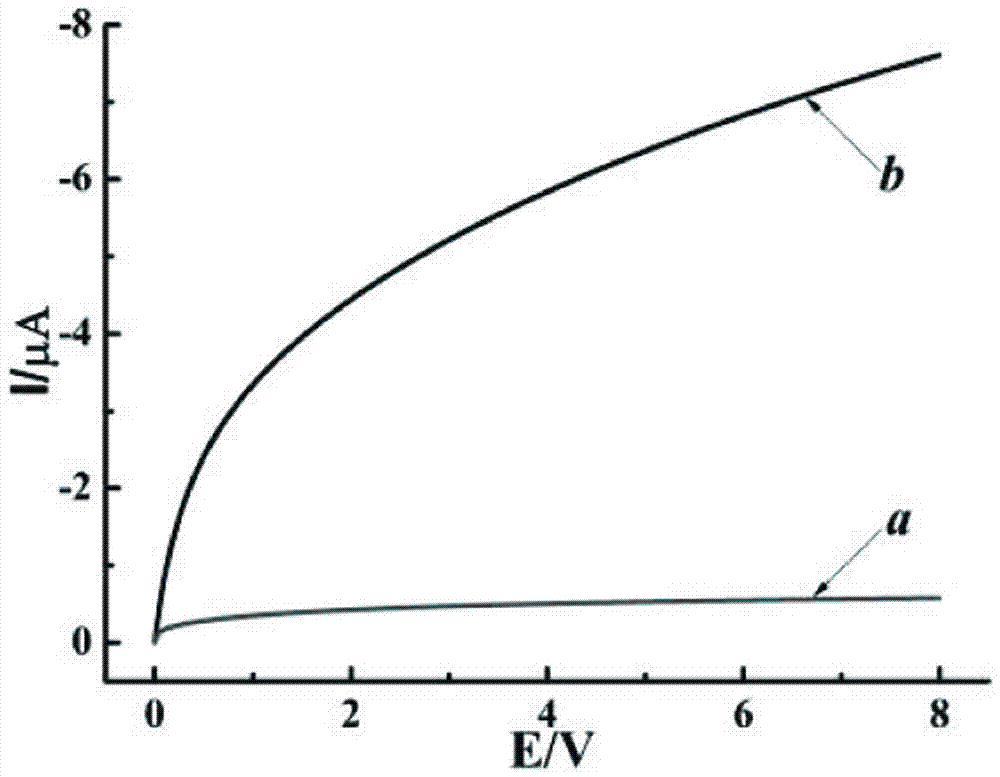

[0027] For pretreatment, first polish the glassy carbon electrode on sandpaper, and then polish it with 0.3μm aluminum oxide powder until the surface of the glassy carbon electrode appears mirrored; then ultrasonically clean it in double distilled water for 2 to 3 minutes, take it out, and use Rinse with double distilled water and wipe dry with filter paper to obtain a bare glassy carbon electrode; put the bare glassy carbon electrode into 1.0×10 -3 mol / L of K 3 Fe(CN) 6 And 0.1mol / L KNO 3 Measure the cyclic voltammogram of the mixed aqueous solu...

Embodiment 2

[0031] A multi-wall carbon nanotube / poly-L-histidine composite material modified glassy carbon electrode includes a glassy carbon electrode on which poly-L-histidine and multi-wall carbon nanotubes are sequentially deposited on the surface of the glassy carbon electrode.

[0032] A preparation method of the multi-wall carbon nanotube / poly-L-histidine composite material modified glassy carbon electrode, which comprises the following steps:

[0033] For pretreatment, first polish the glassy carbon electrode on sandpaper, and then polish it with 0.3μm aluminum oxide powder until the surface of the glassy carbon electrode appears mirrored; then ultrasonically clean it in double distilled water for 2 to 3 minutes, take it out, and use Rinse with double distilled water and wipe dry with filter paper to obtain a bare glassy carbon electrode; put the bare glassy carbon electrode into 1.0×10 -3 mol / L of K 3 Fe(CN) 6 And 0.1mol / L KNO 3 Measure the cyclic voltammogram of the mixed aqueous solu...

Embodiment 3

[0037] A multi-wall carbon nanotube / poly-L-histidine composite material modified glassy carbon electrode includes a glassy carbon electrode on which poly-L-histidine and multi-wall carbon nanotubes are sequentially deposited on the surface of the glassy carbon electrode.

[0038] A preparation method of the multi-wall carbon nanotube / poly-L-histidine composite material modified glassy carbon electrode, which comprises the following steps:

[0039] For pretreatment, first polish the glassy carbon electrode on sandpaper, and then polish it with 0.3μm aluminum oxide powder until the surface of the glassy carbon electrode appears mirrored; then ultrasonically clean it in double distilled water for 2 to 3 minutes, take it out, and use Rinse with double distilled water and wipe dry with filter paper to obtain a bare glassy carbon electrode; put the bare glassy carbon electrode into 1.0×10 -3 mol / L of K 3 Fe(CN) 6 And 0.1mol / L KNO 3 Measure the cyclic voltammogram of the mixed aqueous solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com