Manufacturing method of composite material ultra-light solar cell substrate

A technology of solar cells and solar substrates, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as bonding air bubbles, achieve the effects of reducing weight, reducing its own weight, and ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

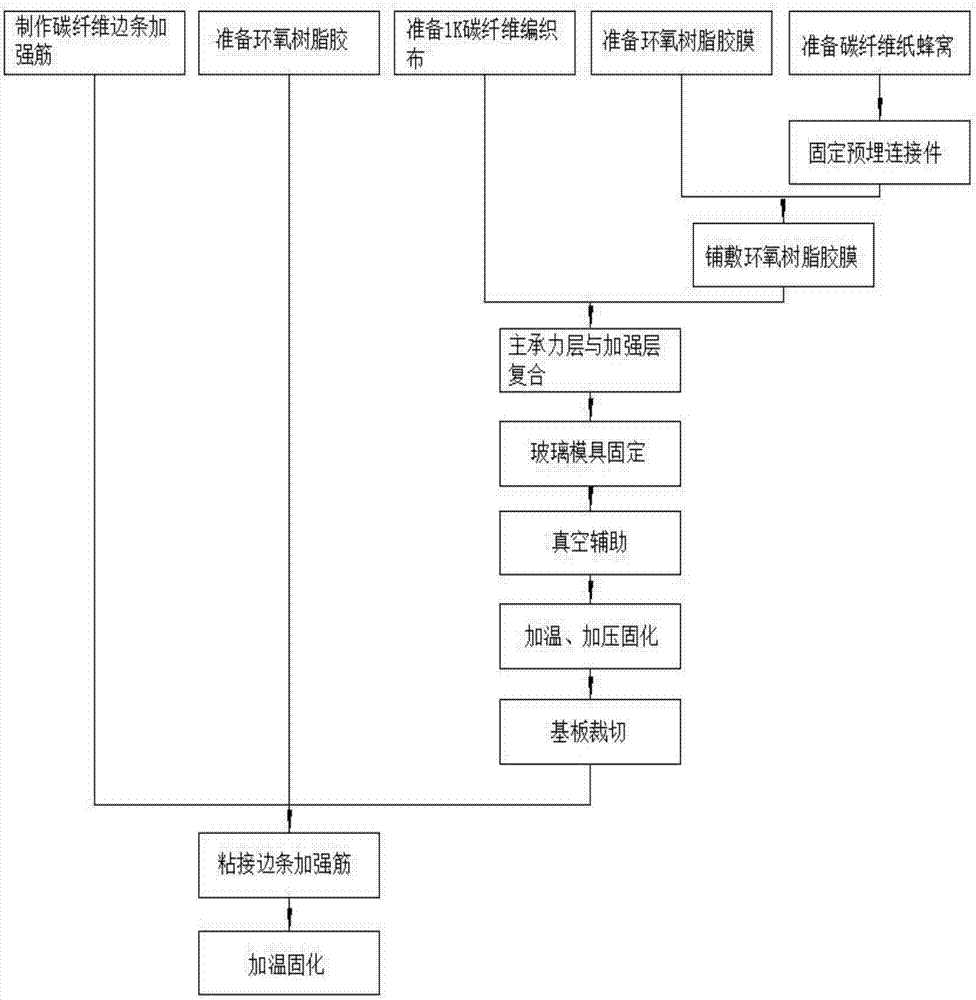

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with accompanying drawing:

[0039] The present invention is method specified according to conventional structural standards for solar cell substrate structures.

[0040] The related technologies involved in the present invention include carbon fiber paving technology, honeycomb structure interlayer technology, sandwich structure composite technology, vacuum coating technology, rib beam structure technology, pre-embedded connection technology, heating and pressure curing methods.

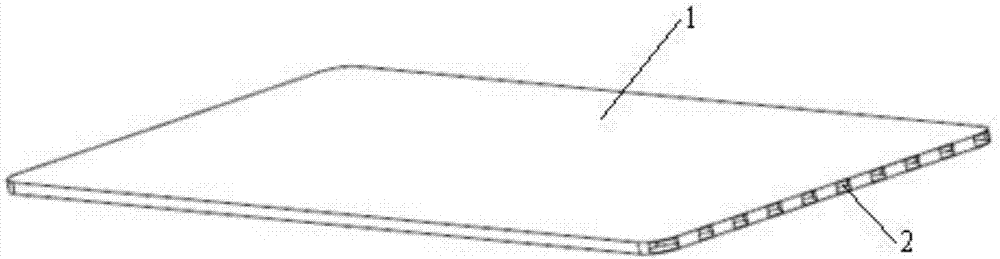

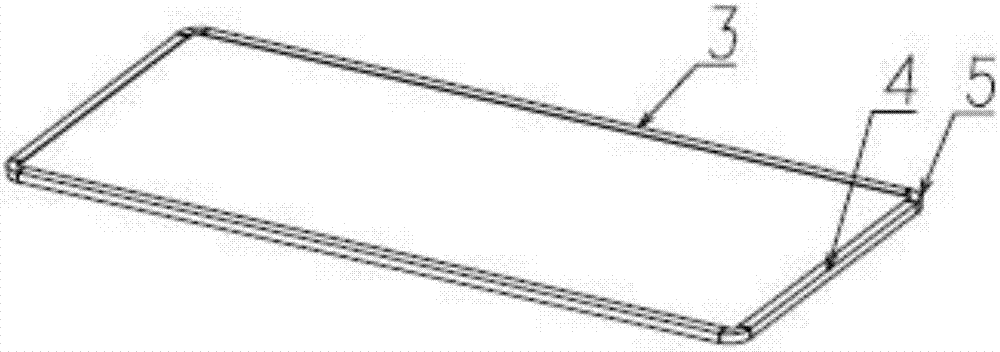

[0041] The present invention adopts 1K carbon fiber twill weave cloth 1 as raw material, adopts plexiglass plate as mould, carbon fiber prepreg fabric to make side ribs, uses polycarbonate plate to make pre-embedded connector 6, and places battery substrate in glass mold 7 for prefabrication Part 8, when the glass mold 7 is evacuated as a whole, the air in the cavity is discharged with the vacuum nozzle 10, and as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com