Method for grafting carbonate on surface of graphene oxide

A technology of carbonate and oxidized rock, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve problems such as inability to graft, and achieve the effects of simple preparation method, high product generation rate, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

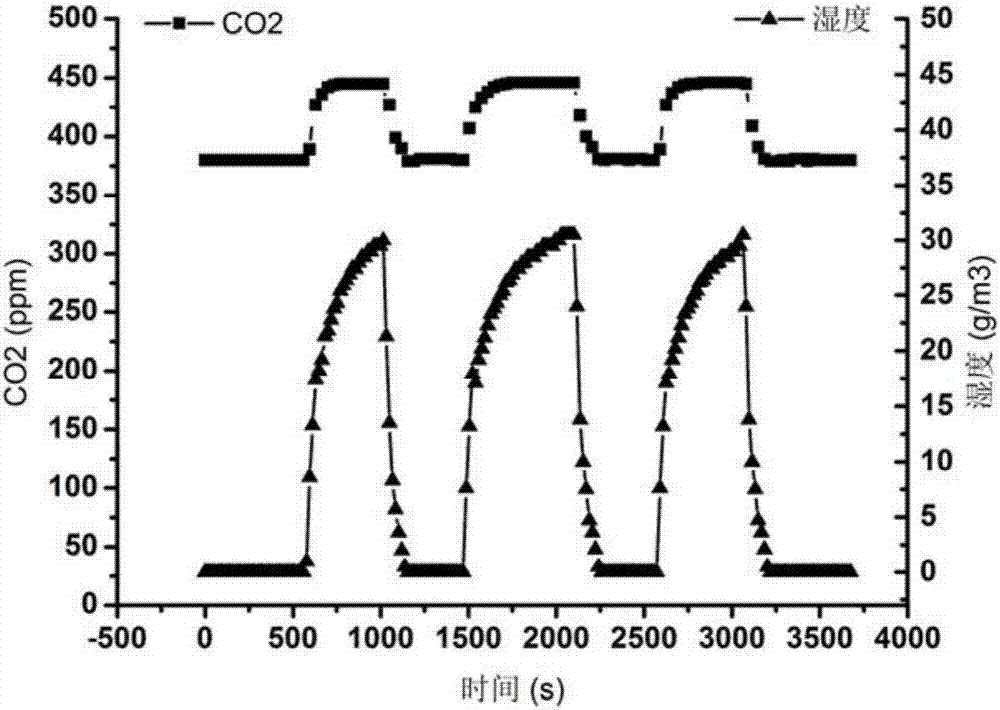

Image

Examples

Embodiment Construction

[0027] This embodiment relates to a preparation method of grafting carbonate on the surface of graphene oxide, comprising the following steps,

[0028] Step 1, weigh 5g of natural graphite flakes and 2.5g of sodium nitrate and add them to 130ml of concentrated sulfuric acid, and react for 2h under ice bath conditions; then add 15g of potassium permanganate and continue to react for 2h under ice bath; Move it into an oil bath at 35°C to continue the reaction for 1 hour; then add 230ml of ionized water to the above reaction solution, raise the temperature to 98°C and continue the reaction for 30 minutes; finally add 10ml of hydrogen peroxide and 400ml of deionized water and stir for 1 hour to stop the reaction; the final product is dilute Hydrochloric acid and deionized water are repeatedly centrifuged and washed to remove impurities and peel off graphite oxide to obtain a graphene oxide solution;

[0029] Step 2: Take 100 ml of the graphene oxide solution prepared in Step 1, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com