A kind of graphene-reinforced magnesium-based composite material containing long-period structure and preparation method thereof

A long-period structure and composite material technology, applied in the field of metal composite materials, can solve problems such as lack of good solutions, and achieve the effects of avoiding bad interface compounds, improving strength and elastic modulus, and high elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

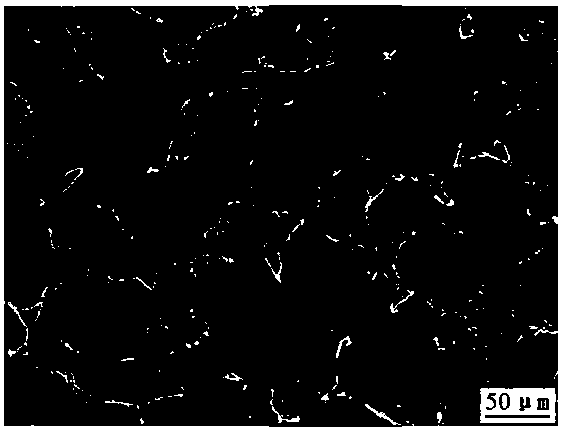

Image

Examples

preparation example Construction

[0035] The preparation method of the magnesium-based composite material containing long-period structure strengthened by graphene of the present invention, the steps are as follows:

[0036] (1) Preparation of Mg-Y-Zn-Ca-Zr-Sb magnesium alloy: 1) Ingredients: raw materials are pure Mg, pure Zn, pure Ca, pure Sb, Mg-40wt% Y master alloy, Mg-20wt.% Zr master alloy, according to the mass percent batching;

[0037] 2) Baking material: Preheat pure Mg, pure Zn, pure Ca, pure Sb, Mg-40wt.%Y master alloy and Mg-20wt.%Zr master alloy at 200~260℃ for more than 4 hours;

[0038] 3) Melting Mg, Zn and Ca: Use a crucible resistance furnace to melt the dried pure magnesium. After the pure magnesium is melted, add pure Zn at 680~720°C. After the pure Zn is melted, the melt temperature rises to 680~ Add pure Ca at 720°C;

[0039] 4) Add Y, Zr and Sb: After pure Ca is melted, add Mg-40wt.%Y master alloy when the melt temperature reaches 730~760℃, and after the Mg-40wt.%Y master alloy is mel...

Embodiment 1

[0048] The graphene-reinforced magnesium-based composite material containing long-period structure in this embodiment is made by adding graphene into the magnesium alloy matrix, and the magnesium alloy matrix is composed of magnesium alloy powder and magnesium alloy sheet, wherein graphene and The mass ratio of the magnesium alloy powder is 1:3, and the mass ratio of graphene and magnesium alloy powder as a whole to the magnesium alloy plate is 1:6; the components and mass percentages of the magnesium alloy matrix are: 3wt.%Y, 1wt.%Zn, 0.2wt.%Ca, 0.2wt.%Zr, 0.2wt.%Sb, and the balance is Mg. The above components are prepared by smelting process to obtain Mg-3Y-1Zn-0.2Ca containing LPSO structure -0.2Zr-0.2Sb alloy, for Mg-3Y-1Zn-0.2Ca-0.2Zr-0.2Sb alloy containing LPSO structure, use atomization method to obtain magnesium alloy powder, for Mg-3Y-1Zn-0.2 containing LPSO structure The Ca-0.2Zr-0.2Sb alloy is homogenized to obtain a magnesium alloy plate.

[0049] The preparatio...

Embodiment 2

[0064]The graphene-reinforced magnesium-based composite material containing long-period structure in this embodiment is made by adding graphene into the magnesium alloy matrix, and the magnesium alloy matrix is composed of magnesium alloy powder and magnesium alloy sheet, wherein graphene and The mass ratio of the magnesium alloy powder is 1:5, and the mass ratio of graphene and magnesium alloy powder as a whole to the magnesium alloy plate is 1:10; the components and mass percentages of the magnesium alloy matrix are: 9wt.%Y, 3wt.%Zn, 2wt.%Ca, 1wt.%Zr, 0.8wt.%Sb, and the balance is Mg. The above components are prepared by melting process to obtain Mg-9Y-3Zn-2Ca-1Zr- 0.8Sb alloy, for Mg-9Y-3Zn-2Ca-1Zr-0.8Sb alloy containing LPSO structure, magnesium alloy powder is obtained by atomization method, for Mg-9Y-3Zn-2Ca-1Zr-0.8Sb alloy containing LPSO structure The magnesium alloy plate is obtained by homogenization treatment.

[0065] The preparation method of the graphene-enhan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com