Method for comprehensively detecting N-nitrosamine content in meat products

A technology for meat products and nitrosamines, which is used in measuring devices, instruments, scientific instruments, etc., achieves the effects of low requirements for instruments, convenient popularization and application, and strong ability to remove interfering substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for comprehensively detecting N-nitrosamine content in meat products, comprising the following steps:

[0042] (1) Sample extraction: Weigh 10g of crushed commercially available sausage, add 20mL of acetonitrile, 10mL of n-hexane and 2g of anhydrous magnesium sulfate, vortex at a speed of 1000rpm for 1min, and ultrasonicate at a temperature of 35°C and an ultrasonic frequency of 60kHZ Extract for 15 minutes, centrifuge at 5000rpm for 5 minutes, pour out the supernatant, keep the acetonitrile layer and discard the n-hexane layer, then repeat the extraction of meat products twice with acetonitrile, combine the extracts, and rotate them under reduced pressure at 50°C until nearly dry, then use acetonitrile Dilute to 5mL, shake well;

[0043] (2) Purification: Measure 1.5mL of the solution after constant volume into a 2mL stoppered centrifuge tube filled with C18 / PSA powder, in which C18 powder is 100mg, PSA powder is 50mg, vortex for 1min, centrifuge at 12000 for ...

Embodiment 2

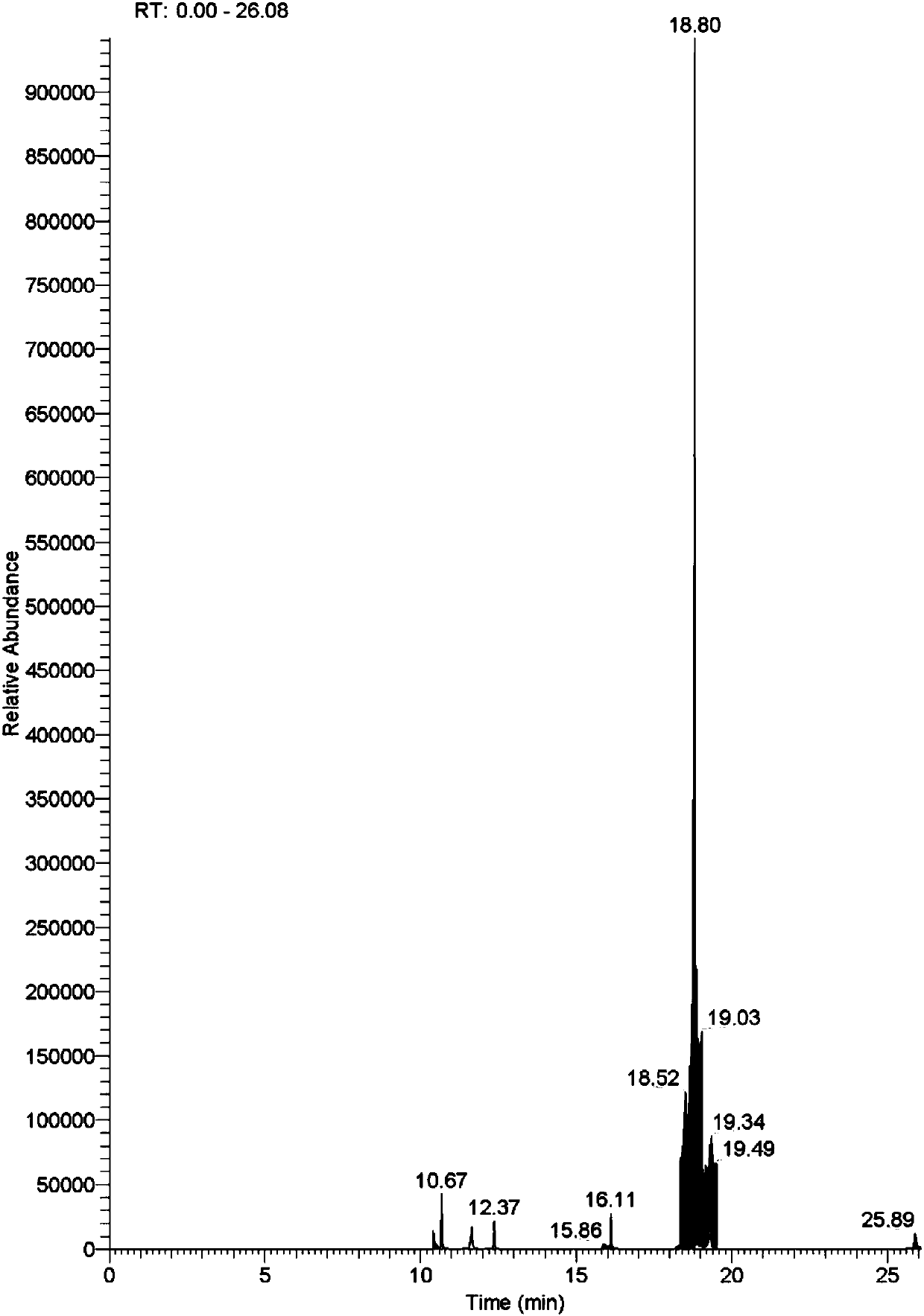

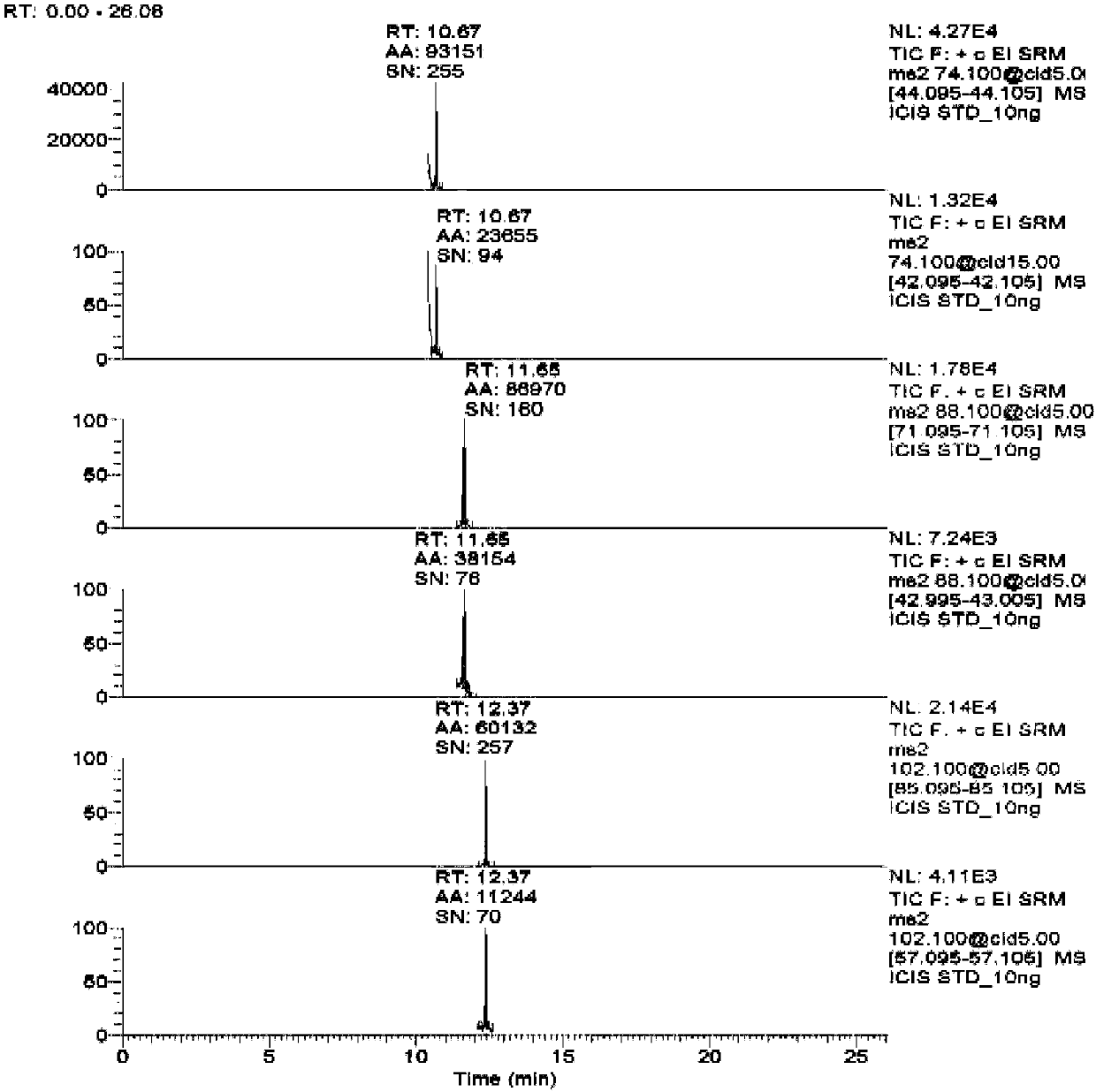

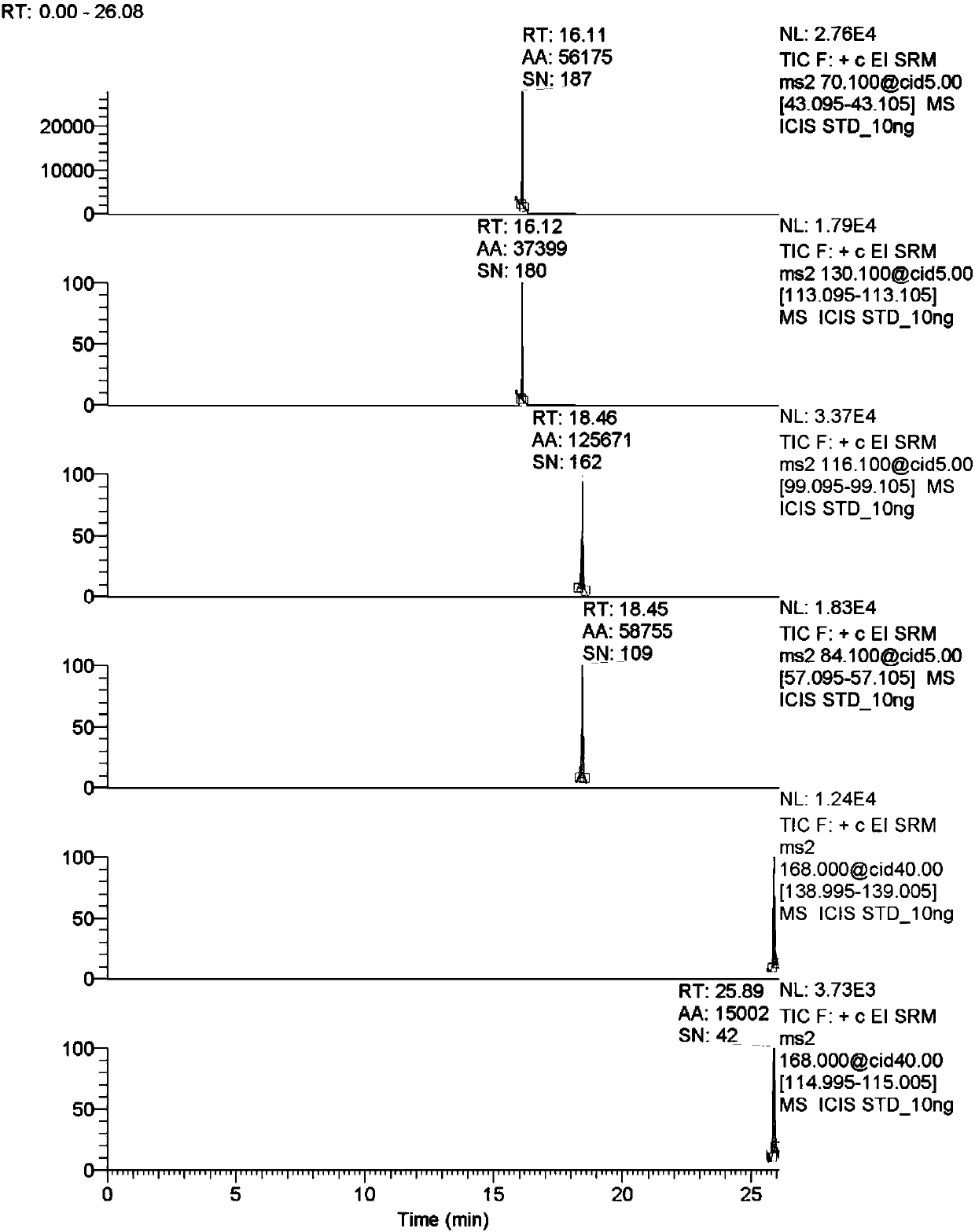

[0057] Take 10 g of blank meat products and add 20 µL of 9 kinds of N-nitrosamine mixed standard solutions with a concentration of 1 µg / mL to obtain standard meat products. Then follow the steps (1)-(3) of Example 1 to operate. The total ion current chromatogram and quantitative qualitative ion extraction chromatograms of blank meat products plus 9 kinds of N-nitrosamine standards are as follows: Figure 4 , Figure 5a , Figure 5b , Figure 5c shown. The total ion current chromatogram and quantitative qualitative ion extraction chromatogram of blank meat products without N-nitrosamine standard are as follows: Figure 6 , Figure 7a , Figure 7b and Figure 7c shown. It can be seen from the figure that the integrated Figures 5a-5c and Figures 7a-7c , the separation between the target peak and the impurity peak is high, and it is not interfered by the impurity peak, which shows that the method is reliable and effective.

[0058] Quality control: a. The response abu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com