Charging loop for internal resistance compensation of wind turbine generator set variable-pitch super capacitor, and control method thereof

A technology of supercapacitors and wind turbines, applied in battery circuit devices, circuit devices, collectors, etc., can solve problems such as limited capacitive response and response ability, limited compensation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

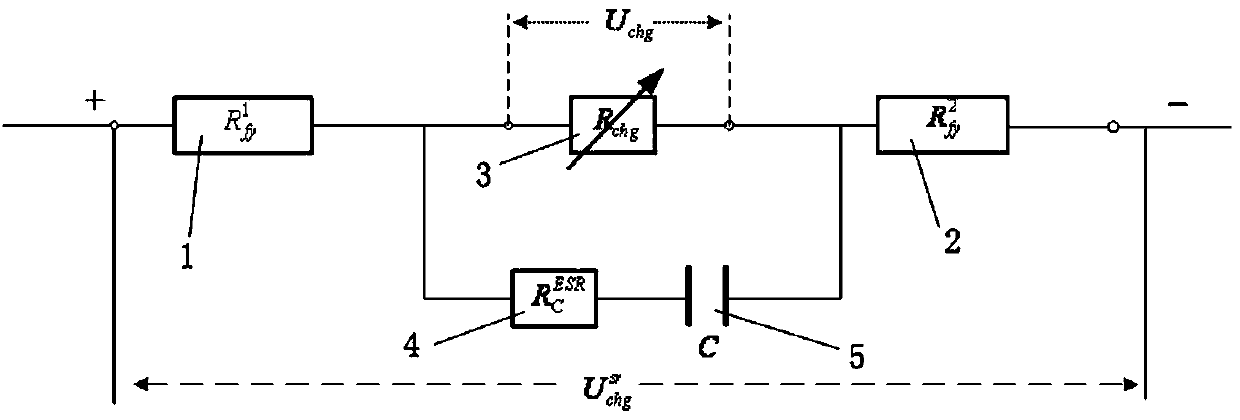

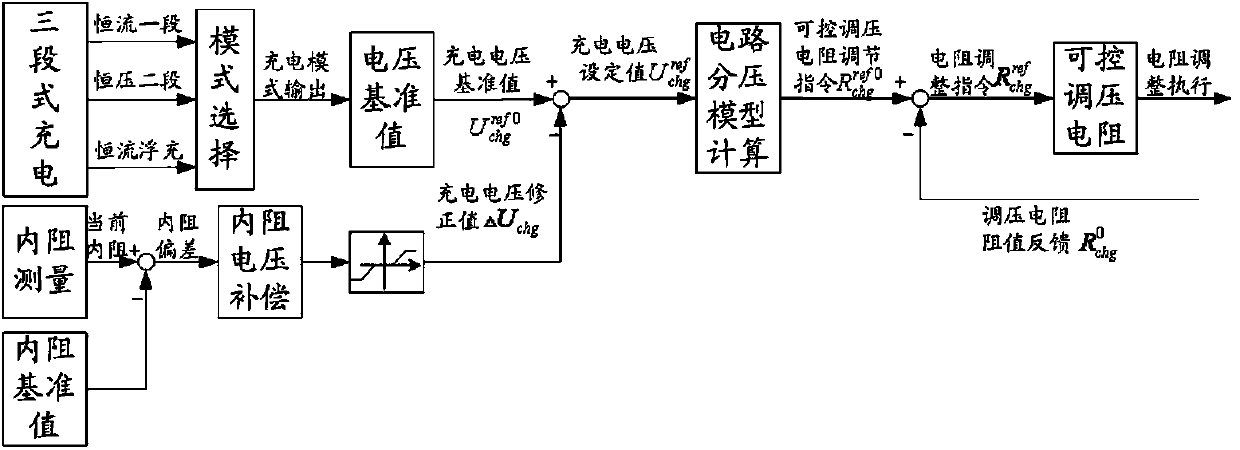

[0034]This embodiment is a charging circuit for internal resistance compensation of a wind turbine pitch supercapacitor, including two voltage divider resistors and a resistor, the two voltage divider resistors are No. 1 voltage divider resistor 1 and No. 2 voltage divider resistor 2, and a The series resistance between No. 1 and No. 2 voltage dividing resistors is a controllable voltage regulating resistor 3, and the two ends of the controllable voltage regulating resistor 3 are connected in parallel with an internal resistance detection circuit, and the internal resistance detection circuit is connected with the controllable voltage regulation The resistors 3 are connected in parallel, and the parallel circuit composed of the internal resistance detection circuit and the controllable voltage regulating resistor 3 is connected in series between the No. 1 voltage dividing resistor 1 and the No. 2 voltage dividing resistor 2 . The internal resistance detection circuit is a super...

Embodiment 2

[0055] The temperature difference between winter and summer in a wind farm in Ningxia is 30°C. The measured temperature difference of the backup power supply shell in winter and summer is more than 50°C. Switching power supply output for voltage trimming. Install the internal resistance detector and run it for one year. Taking the internal resistance corresponding to 25°C as the reference internal resistance, and making monthly statistics, the measured actual internal resistance fluctuates within the range of 25%-30% above and below the reference.

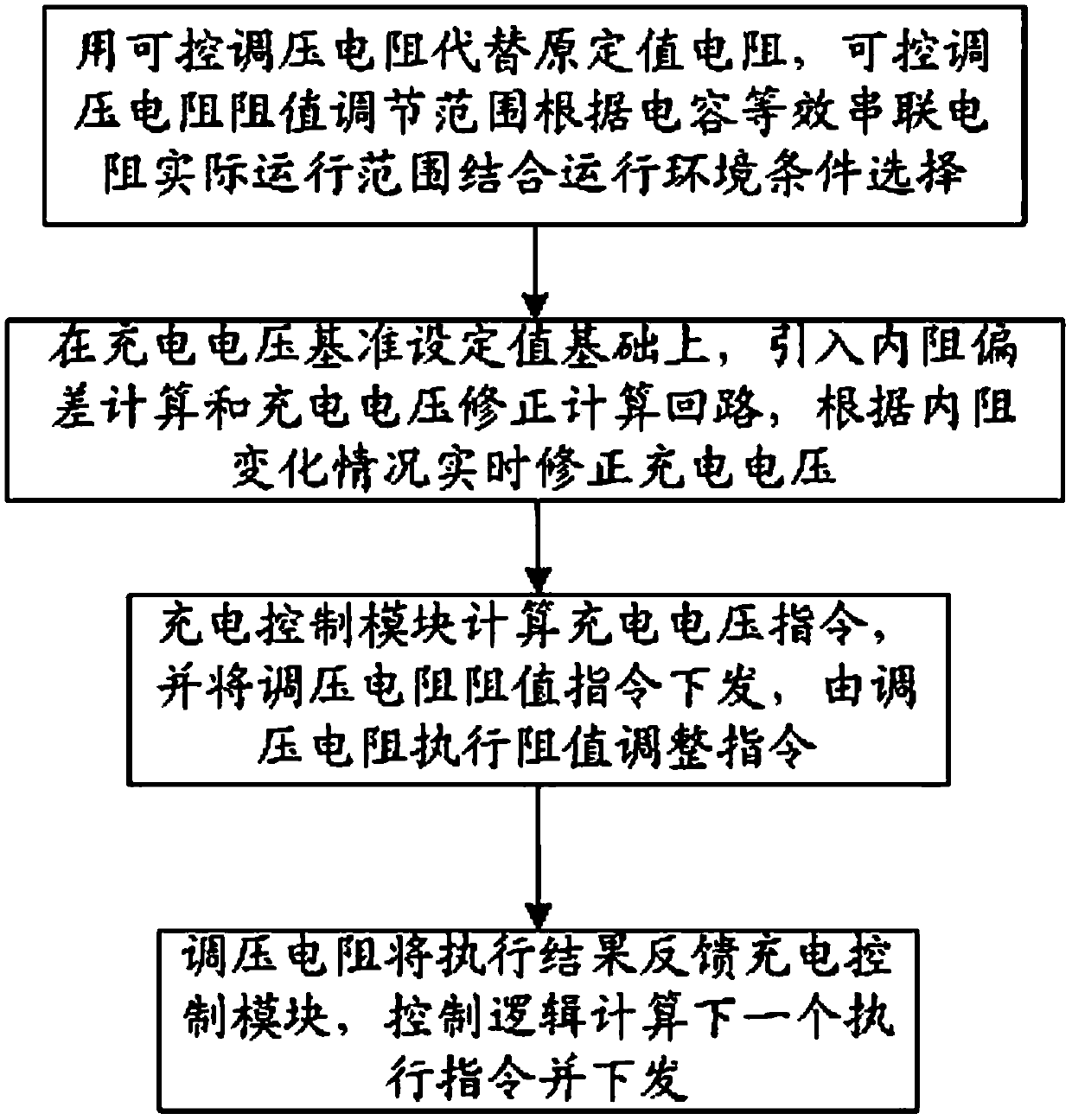

[0056] According to the original charging circuit, the adjustment range of the resistance value of the controllable voltage regulating resistor 3 is calculated to be 0 to 1.43 times the original nominal resistance, and accordingly the adjustment range of the resistance value of the controllable voltage regulating resistor 3 is 0 to 1.5 times the original nominal resistance, and replaced In the charging circuit, the original fixed v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com