Intelligent wrapping device for granular medicine

A kind of drug and intelligent technology, applied in the field of granular drug intelligent packaging device, can solve the problems of poor effect, reduce the rate of drug refusal in children, and large institutions, so as to reduce the growth of bacteria, reduce the probability of drug refusal, and ensure stable work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

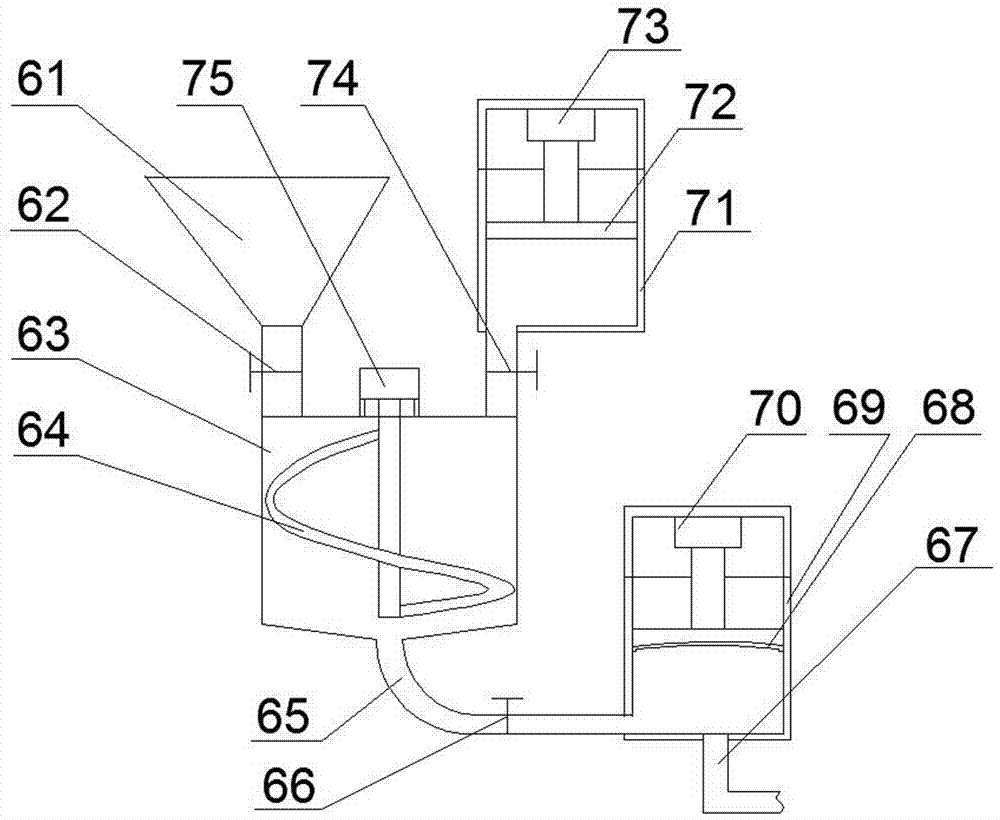

[0063] like Figure 1-Figure 18 Shown: an intelligent packaging device for granular medicines, comprising a casing 1, a rotating mechanism arranged in the casing 1 for transporting materials, arranged on the first side of the rotating mechanism and located on the casing 1 The feeding mechanism, the transfer mechanism 10 disposed on the second side of the rotating mechanism and located on the casing 1, the unloading mechanism disposed on the third side of the rotating mechanism and located in the casing 1, A sterilization mechanism 28 is provided on the housing 1 for sterilization, and is arranged outside the housing 1 and is used to coordinately control the rotation mechanism, the feeding structure, the transfer mechanism, the unloading mechanism and the sterilization mechanism the control mechanism 19;

[0064] The sterilization mechanism 28 includes a micro steam generator 281, a sterilization tube 282 connected to the micro steam generator 281, a sterilization heating wire...

Embodiment 2

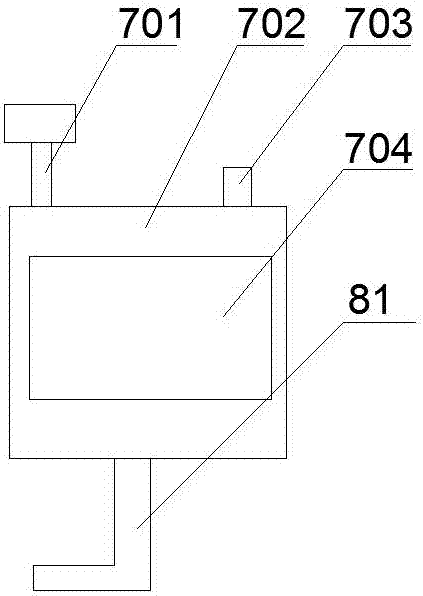

[0081] The difference between the second embodiment and the first embodiment is that the auxiliary material piston in the auxiliary material warehouse is arranged on the auxiliary material piston 72 and the auxiliary material push rod 73 which is matched with the outer wall of the auxiliary material tank 71 is arranged on the auxiliary material push rod 73 . The solenoid valve 74 on the conduit between the lower part of the auxiliary material tank 71 and the mixing bin 63 .

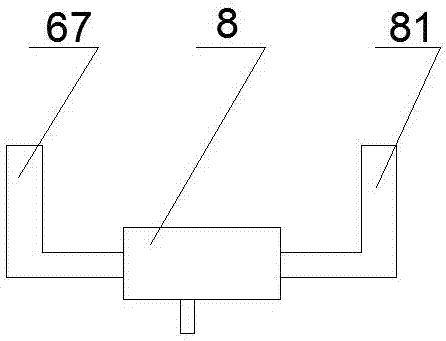

[0082] The material pressing module includes a material pressing bin 69, a pressing material piston 68 arranged in the material pressing material 69 warehouse, and a material pressing push rod 70 on the pressing material piston 68 and fixedly connected with the outer wall of the material pressing material bin 69. , which is arranged at the lower part of the pressure bin 69 and is connected to the second end of the three-way valve 8 .

[0083] An adjustment hole is arranged at the upper end of the central ...

Embodiment 3

[0087] The difference from the second embodiment is that: the peeling module includes a plurality of air injection units 121 arranged at the bottom of the forming module, a first air injection pipe 23 connected to the plurality of air injection units, and the first air injection pipe 23 The first solenoid valve 231 is disposed at the second air injection pipe 232 at the lower part of the first air injection pipe 23 , and the second air injection pipe 232 communicates with the air outlet hole 26 .

[0088] The air blowing unit 121 includes a plurality of air nozzles 1211 , an elastic film 1212 disposed at the outlet of the air nozzles 1211 , and an air outlet gap 1213 disposed in the middle of the elastic film 1212 .

[0089] The molding module further includes a hemispherical cover 4 that is matched with the hemispherical molding groove. The top surface of the hemispherical cover is provided with a feeding hole 41 that is matched with the material spraying module. The forming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com