Preparation method and application of polyethyleneimine-crosslinked graphene oxide/titanium dioxide-laminated composite film

A technology of polyethyleneimine and titanium dioxide, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as film rupture, unstable mechanical properties of graphene oxide film, and falling off of graphene oxide particles , to achieve stable separation performance, dense and clear microscopic layered structure, and complete and continuous macroscopic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

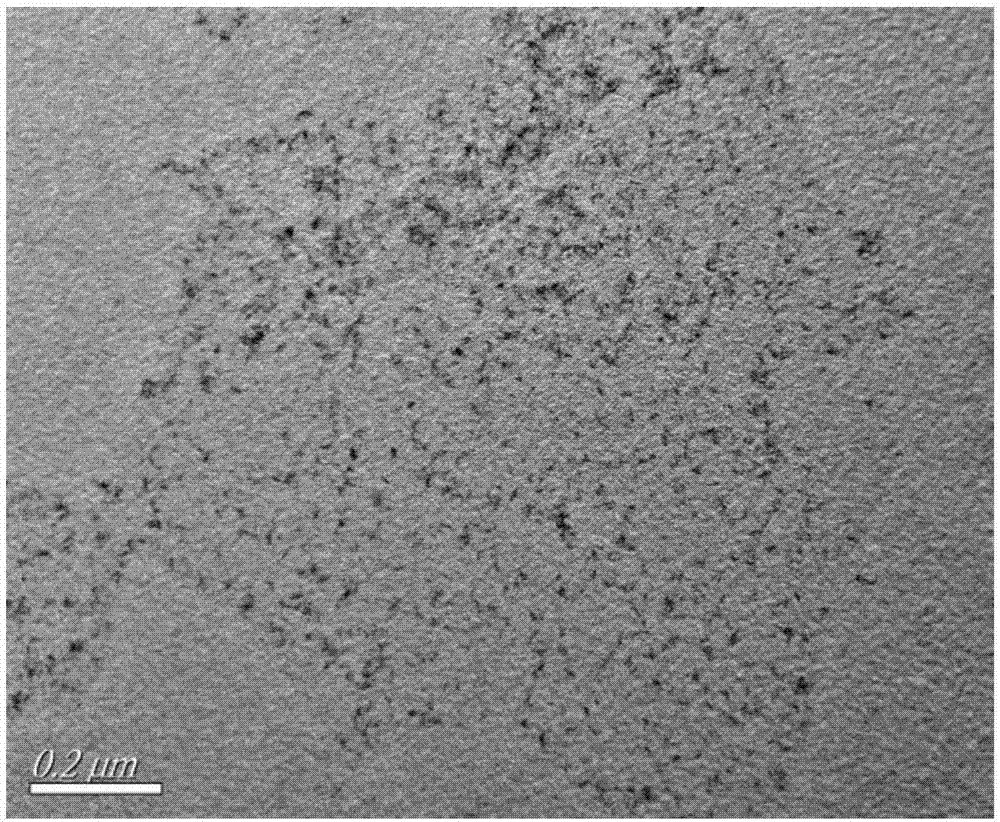

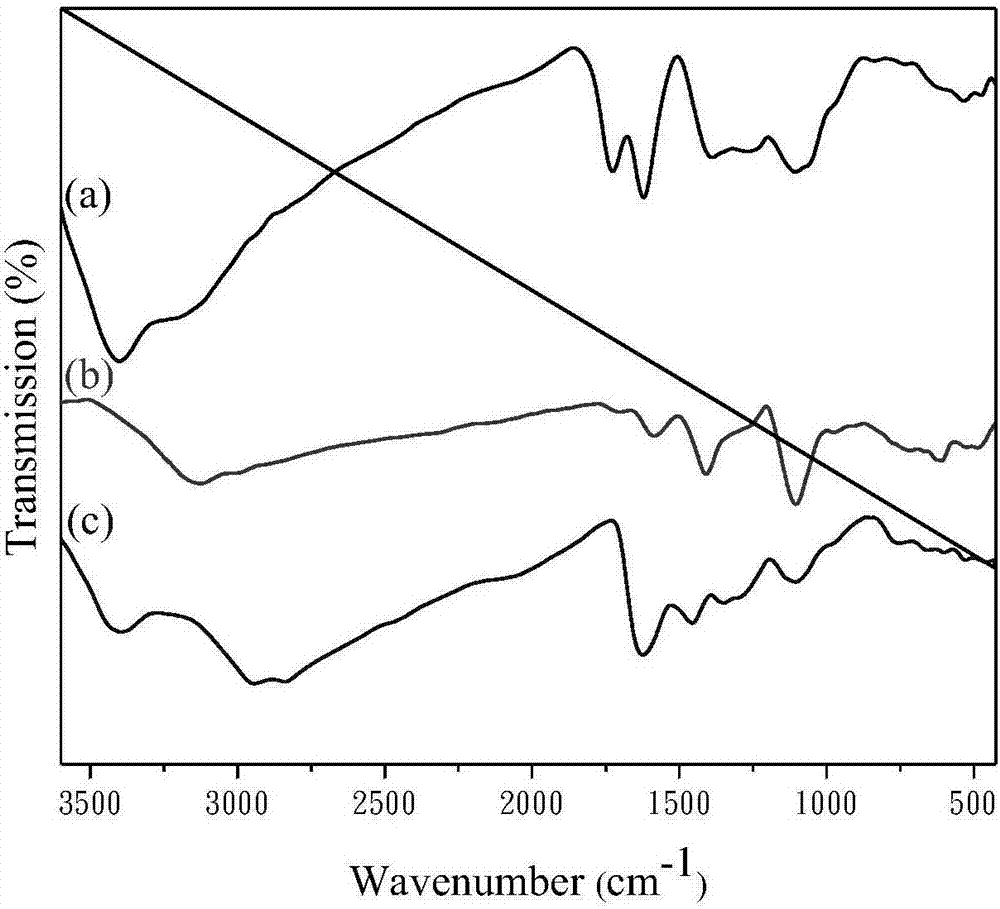

[0026] (1) One-step synthesis method to prepare graphene oxide / titanium dioxide nanocomposites

[0027] In a 250mL beaker, add 12.5mg graphene oxide, 40mL deionized water, ultrasonic 3h; add 60mg Ti(SO 4 ) 2 , the mixed solution was heated at 60°C for 24 hours, centrifuged, and washed with water; the obtained product was dispersed in 40mL of water, and 1mol / L ammonia water was added dropwise to pH=10 to obtain a stable graphene oxide / titanium dioxide dispersion.

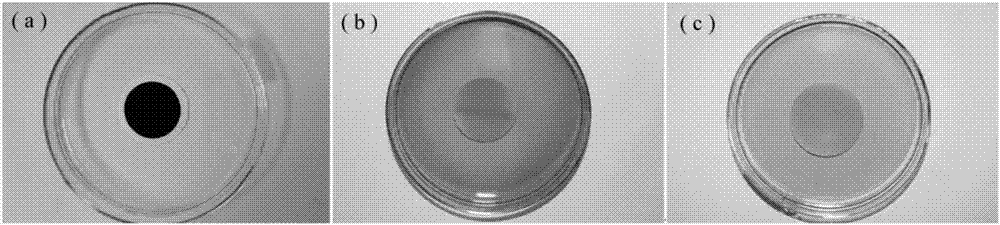

[0028] (2) Preparation of polyethyleneimine cross-linked graphene oxide / titanium dioxide layered composite film

[0029] Stir the graphene oxide / titanium dioxide dispersion prepared in step 1 for 30 minutes, add 25 mg of polyethyleneimine, ultrasonicate for 1 hour, and use a mixed cellulose membrane with a pore size of 0.22 μm as the base membrane for the obtained colloidal solution, vacuum filter for 12 hours , treated at 0°C for 30 minutes to obtain a polyethyleneimine-crosslinked graphene oxide / titanium dioxide ...

Embodiment 2

[0034] (1) One-step synthesis method to prepare graphene oxide / titanium dioxide nanocomposites

[0035] In a 250mL beaker, add 25mg graphene oxide, 40mL deionized water, ultrasonic 3h; add 60mg Ti(SO 4 ) 2 , the mixed solution was heated at 60°C for 24 hours, centrifuged, and washed with water; the obtained product was dispersed in 40mL of water, and 1mol / L ammonia water was added dropwise to pH=10 to obtain a stable graphene oxide / titanium dioxide dispersion.

[0036] (2) Preparation of polyethyleneimine cross-linked graphene oxide / titanium dioxide layered composite film

[0037] Stir the graphene oxide / titanium dioxide dispersion prepared in step 1 for 30 minutes, add 25 mg of polyethyleneimine, ultrasonicate for 1 hour, and use a mixed cellulose membrane with a pore size of 0.22 μm as the base membrane for the obtained colloidal solution, vacuum filter for 12 hours , and treated at 50° C. for 1 h to obtain a polyethyleneimine-crosslinked graphene oxide / titanium dioxide la...

Embodiment 3

[0039] (1) One-step synthesis method to prepare graphene oxide / titanium dioxide nanocomposites

[0040] In a 250mL beaker, add 50mg graphene oxide, 40mL deionized water, ultrasonic 3h; add 60mg Ti(SO 4 ) 2 , the mixed solution was heated at 60°C for 24 hours, centrifuged, and washed with water; the obtained product was dispersed in 40mL of water, and 1mol / L ammonia water was added dropwise to pH=10 to obtain a stable graphene oxide / titanium dioxide dispersion.

[0041] (2) Preparation of polyethyleneimine cross-linked graphene oxide / titanium dioxide layered composite film

[0042] Stir the graphene oxide / titanium dioxide dispersion prepared in step 1 for 30 minutes, add 25 mg of polyethyleneimine, ultrasonicate for 1 hour, and use a mixed cellulose membrane with a pore size of 0.22 μm as the base membrane for the obtained colloidal solution, vacuum filter for 12 hours , treated at 100°C for 2 hours to obtain a polyethyleneimine-crosslinked graphene oxide / titanium dioxide lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com