Pipe cutting and welding all-in-one machine

A technology of cutting and welding, integrated machine, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of high cost, inability to adjust pipe materials, unsatisfactory welding effect, etc., and achieve the effect of avoiding mutual interference and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

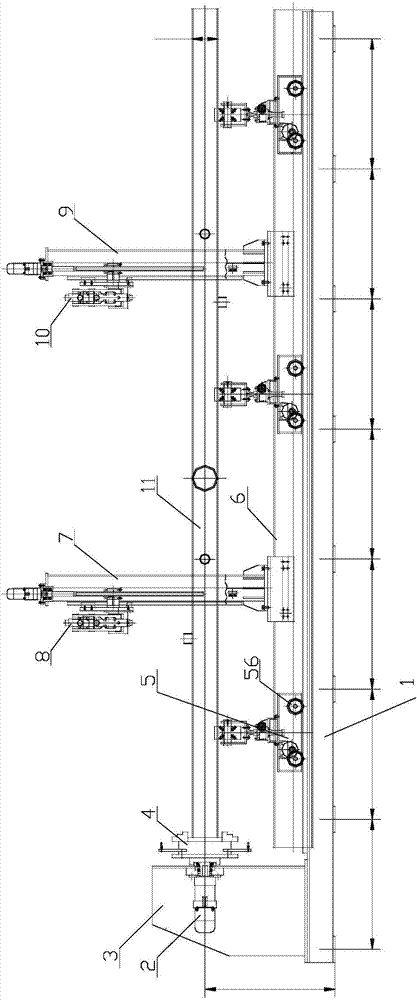

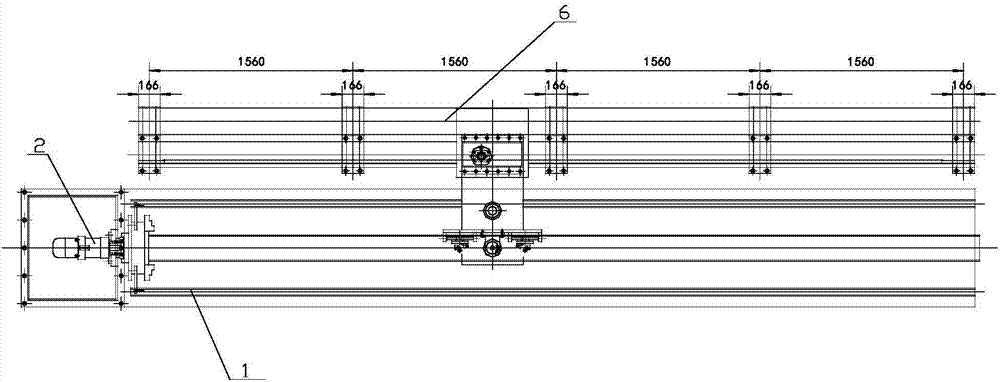

[0023] Embodiment 1: as Figure 1 to Figure 5 The cutting and welding integrated machine shown includes a driving head frame 3, a fixed base 1, a moving slide 6, a cutting head supporting plate 7, and a welding torch head 10 supporting plate 9;

[0024] The driving head frame 3 is arranged at the end of the fixed base 1 and is provided with a pneumatic clamping chuck 4 facing the end face of the fixed base 1. The pneumatic clamping chuck 4 is connected with a rotary servo motor 2 to drive it to rotate, and the pneumatic clamping chuck 4 Through the action of the solenoid valve, the workpiece of Φ65mm~Φ200mm can be clamped;

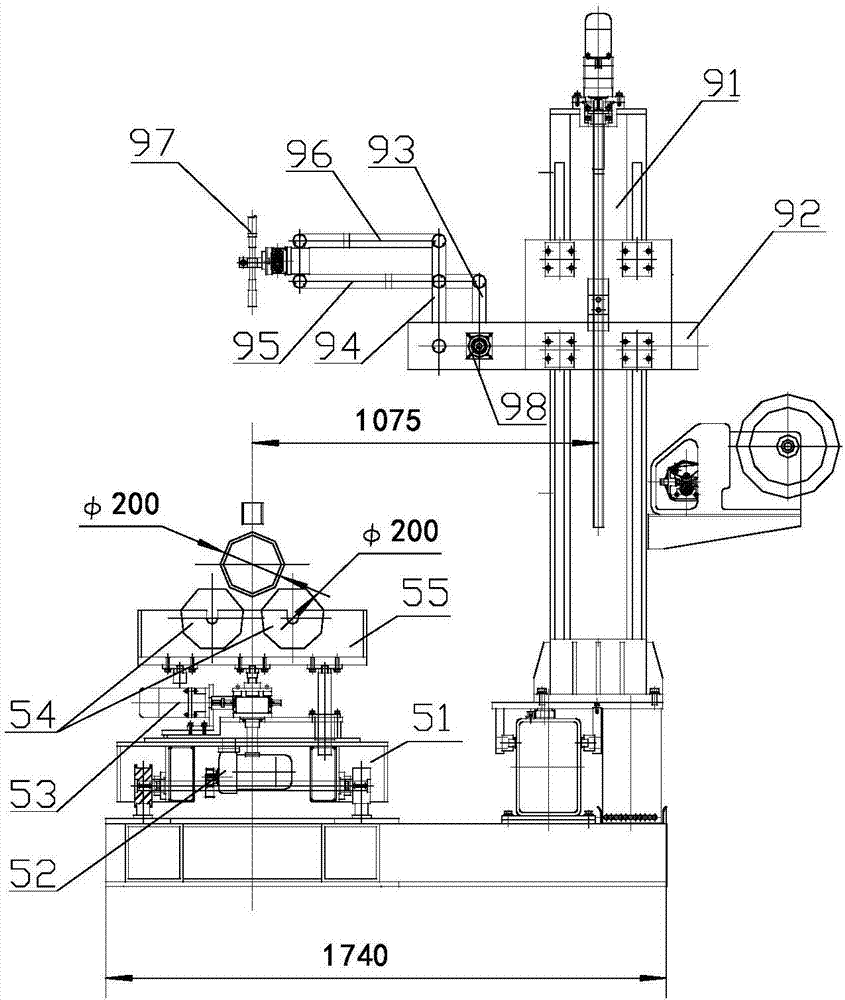

[0025] The centers of the fixed base 1 and the driving head frame 3 are located on a straight line, and there are 3 sets of movable lifting brackets 5 on the fixed base 1; The length of 1 is 6400mm; each set of mobile lifting brackets 5 includes a mobile lifting seat 51, a walking drive motor 52, a lifting drive motor 53, and a lifting bracket; the distan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com