Electric ATV motor integrated rear axle

A rear axle and electric technology, applied in the direction of electric power unit, power unit, axle, etc., can solve the problems of large friction loss of parts, large loss of output dynamic rate, and high repair rate of the whole vehicle, so as to achieve small output power loss and reduce The effect of transmission friction loss and smooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

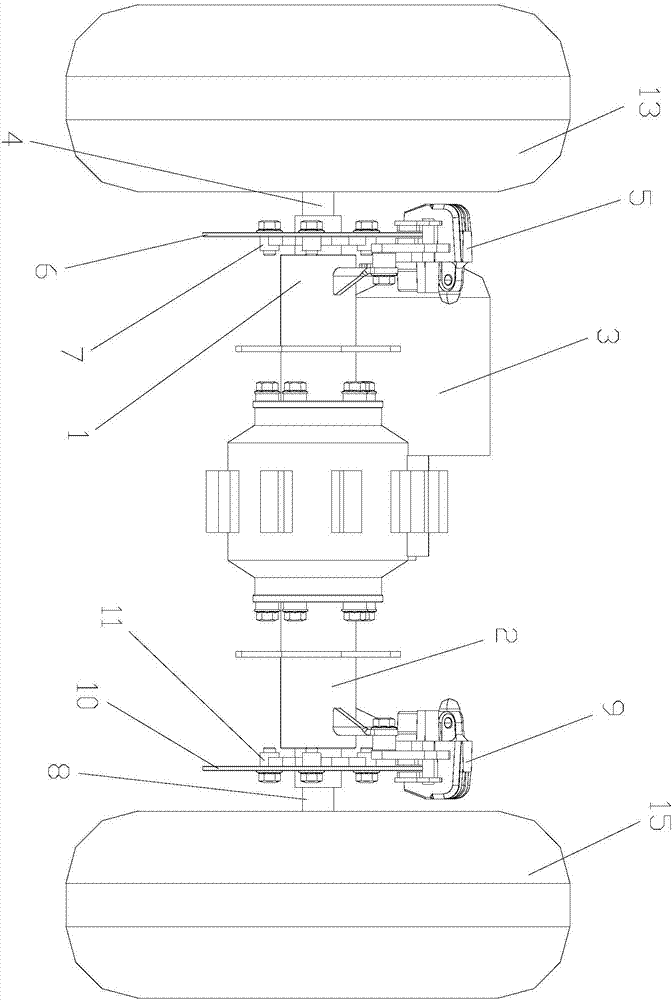

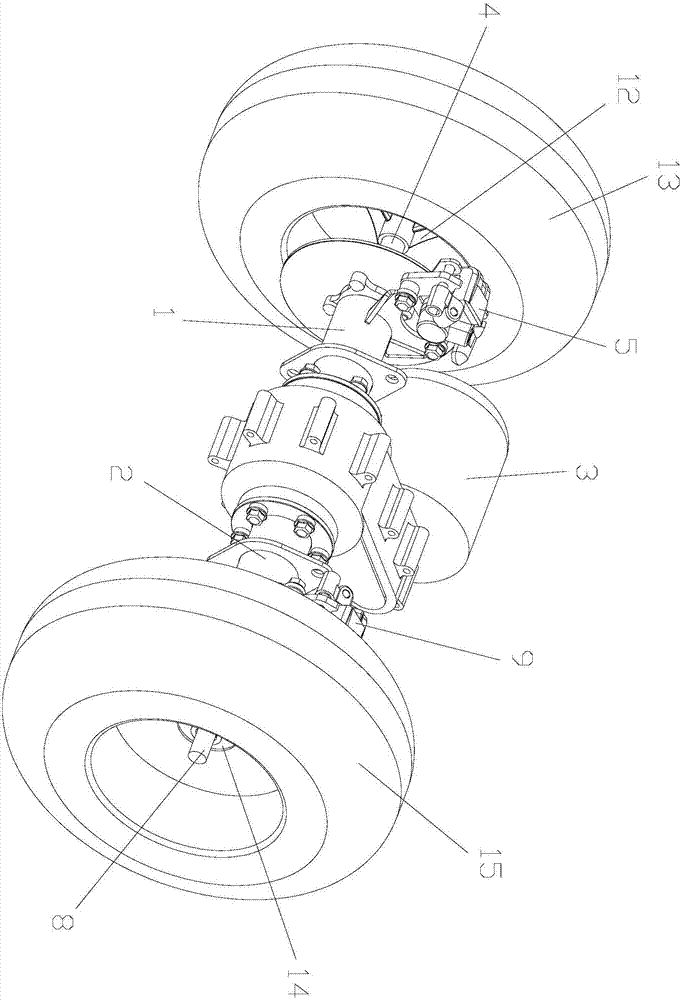

[0014] Referring to the accompanying drawings: the electric ATV motor integrated rear axle in this embodiment includes a left rear axle tube 1 and a right rear axle tube 2, and a differential motor is connected between the left rear axle tube 1 and the right rear axle tube 2 3. The left output end of the differential motor 3 is connected to the left rear axle tube 1, the right output end of the differential motor 3 is connected to the right rear axle tube 2, and the left half shaft 4 is arranged inside the left rear axle tube 1, and the left half shaft 4 is connected to the left output end of the differential motor 3, the left rear axle tube 1 is equipped with a left disc brake 5, the left disc brake 5 is equipped with a left disc brake disc 6, and the left axle shaft 4 is equipped with a left disc brake disc seat 7. The left disc brake disc 6 is installed on the left disc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com