Treatment method of industrial wastewater with high concentration of chlorine ions

A technology for industrial wastewater and treatment methods, which is applied in multi-stage water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect of high processing efficiency, abundant pharmaceutical materials, huge economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

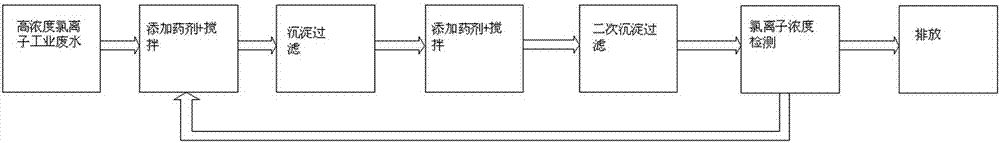

[0016] Embodiment 1: the present invention is implemented in practice, by figure 1 shown, including the following steps:

[0017] 1. First measure the chloride ion concentration in industrial wastewater, take 300ml of industrial wastewater and put it in a beaker, measure the chloride ion concentration with a chloride ion content detector, and the content is 3038.2mg / L;

[0018] 2. Calculate the dosage of the medicament, according to the chlorine ion (Cl - ) concentration to calculate the total content of chloride ions in wastewater, and then calculate the dosage of chemicals based on the total content of chloride ions. The molar ratio of chloride ions to dosage of chemicals is Cl - :NaAlO 2 :CaO=1: 3:9 weigh the medicine;

[0019] 3. Stirring reaction: add sodium metaaluminate and calcium oxide to the industrial wastewater according to the dosage calculated in step 2, stir and react at 28°C for 2.0h, and the stirring speed is 400r / min;

[0020] 4. Standing and filtering: A...

Embodiment 2

[0023] Embodiment 2: the present invention is implemented in practice, by figure 1 shown, including the following steps:

[0024] 1. First measure the chloride ion concentration in the industrial wastewater, take 300ml industrial wastewater and put it in a beaker, measure the chloride ion concentration with a chloride ion content meter, the content is 3812.4mg / L;

[0025] 2. Calculate the dosage of the medicament, according to the chlorine ion (Cl - ) concentration to calculate the total content of chloride ions in wastewater, and then calculate the dosage of chemicals based on the total content of chloride ions. The molar ratio of chloride ions to dosage of chemicals is Cl - :NaAlO 2 :CaO=1: 3:11 Weigh the medicine;

[0026] 3. Stirring reaction: add sodium metaaluminate and calcium oxide to the industrial wastewater according to the dosage calculated in step 2, stir and react at 25°C for 2.0h, and the stirring speed is 450r / min;

[0027] 4. Standing and filtering: After ...

Embodiment 3

[0030] Embodiment 3: the present invention is implemented in practice, by figure 1 shown, including the following steps:

[0031] 1. First measure the chloride ion concentration in industrial wastewater, take 300ml of industrial wastewater and put it in a beaker, measure the chloride ion concentration with a chloride ion content detector, and the content is 4203.8mg / L;

[0032] 2. Calculate the dosage of the medicament, according to the chlorine ion (Cl - ) concentration to calculate the total content of chloride ions in wastewater, and then calculate the dosage of chemicals based on the total content of chloride ions. The molar ratio of chloride ions to dosage of chemicals is Cl - :NaAlO 2 :CaO=1: 3:10.5 Weigh the medicine;

[0033] 3. Stirring reaction: add sodium metaaluminate and calcium oxide to the industrial wastewater according to the dosage calculated in step 2, stir and react at 25°C for 2.5 hours, and the stirring speed is 420r / min;

[0034] 4. Standing and filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com