Activated sludge filtering biochemical reactor and technical process thereof

A biochemical reactor and activated sludge technology, which is applied in filtration treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of increasing sludge disposal costs, limiting biochemical reaction rates, and unmaintainable aeration tanks and other problems, to achieve the effect of high sewage treatment efficiency, highly integrated intelligence, and easy automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

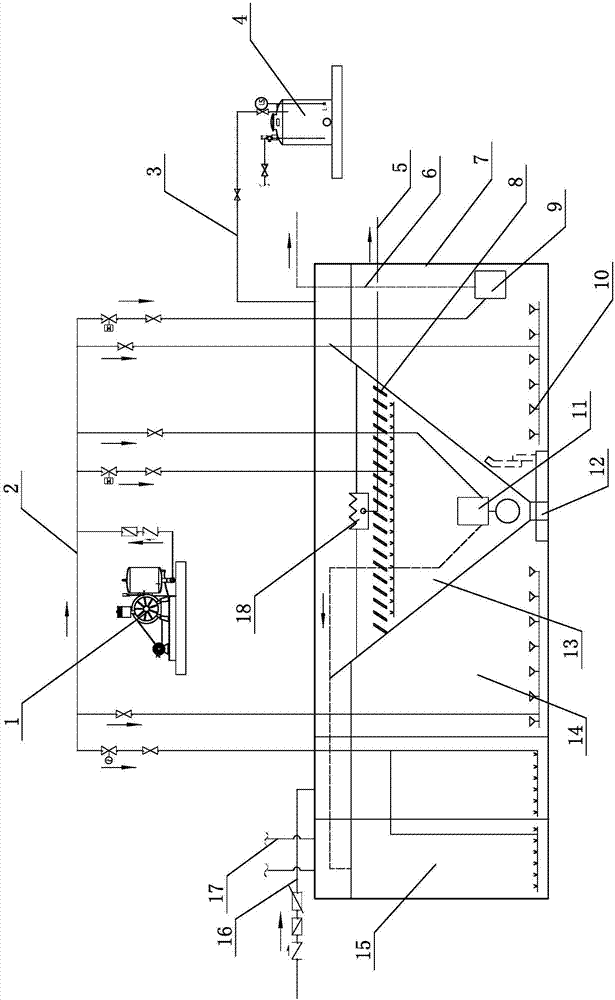

[0029] like figure 1 As shown, the activated sludge filtration biochemical reactor of the present invention includes a reactor housing 7, a biochemical fan 1 and a dosing device 4, and the inside of the reactor housing 7 is respectively provided with an anoxic zone 15, an aerobic zone 14 and The clarification zone 13, the anoxic zone 15, the aerobic zone 14 and the clarification zone 13 are connected successively, and a plurality of through holes are set on the device wall between the anoxic zone 15 and the aerobic zone 14, and are connected by the through holes, and the anoxic zone 15 is externally connected to the water inlet pipeline 16, and the interior of the anoxic zone 15, the aerobic zone 14 and the clarification zone 13 are all equipped with an aerator 10, and the biochemical blower 1 is connected with the aerator 10 through the air pipeline 2, and the aeration not only makes the liquid Oxygenation in contact with air, and due to the agitation of the liquid, the trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com