Device and method for improving municipal sludge dewaterability through microbial cracking reaction

A municipal sludge and pyrolysis reaction technology, applied in biological sludge treatment, dewatering/drying/concentrating sludge treatment, etc., can solve the problems of reducing comprehensive disposal costs and high moisture content of mud cakes, achieving low human control requirements and running The effect of low cost and saving operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

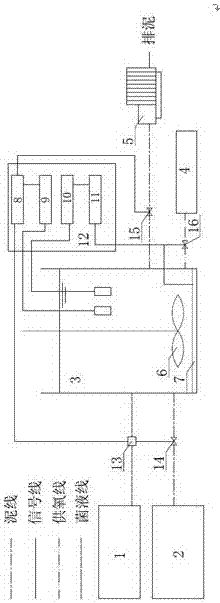

[0038] Embodiment 1: see figure 1 , a device for improving the dewatering performance of municipal sludge through microbial cracking reaction, characterized in that the device includes a reaction tank 3, a control room 12, an oxygen tank 4 and a mechanical dehydrator 5, and a stirring device is arranged in the reaction tank 6 and a heating machine 7, the stirring is arranged above the reaction tank, and the stirring device is close to the bottom of the reaction tank, so that the sludge and the bacteriophage type bacterial liquid are fully mixed in the reaction tank; the heating machine is arranged at the bottom of the reaction tank, The inside of the reaction tank can be within a certain temperature range; the front end of the reaction tank is provided with a sludge inlet, which is connected to the sludge outlet of the previous sludge concentration tank; the rear end of the reaction tank is provided with a sludge outlet, which is connected with the subsequent The sludge inlet ...

Embodiment 2

[0040] Example 2: see figure 1 A method for improving the dewatering performance of municipal sludge by biolysis, the method comprising the following steps:

[0041] 1) Preparation of phage-type bacteria liquid, centrifuge and resuspend the cultured phage-type bacteria, so that the concentration range is 10 3 —10 6 pfu / mL or use the prepared phage-type bacterial solid bacterial agent to activate and make the concentration range within 10 3 —10 6 pfu / mL;

[0042] 2) Discharge the sludge into the reaction tank for stirring pretreatment. The second industrial controller controls the opening of the sludge pump on the sludge delivery pipeline and the start-up of the bacterial liquid dosing machine. The concentrated sludge enters the reaction tank and neutralizes the bacteria Phage-type bacteria are mixed and stirred at a stirring speed of 30-150r / min, so that the final concentration of phage-type bacteria in the sludge is 10 2 —10 5 pfu / mL;

[0043] 3) Carry out cracking tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com