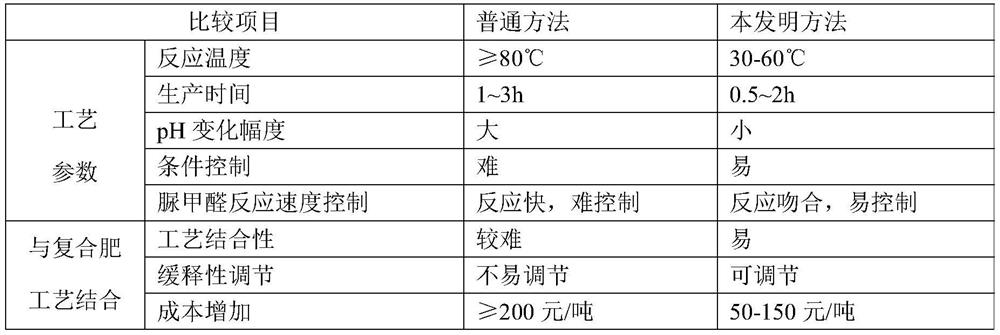

A method of direct granulation to produce urea-formaldehyde slow-release compound fertilizer by low-temperature concentrated solution method

A technology of slow-release compound fertilizer and concentrated solution, which is applied in the directions of urea compound fertilizer, nitrogen fertilizer, fertilization device, etc., can solve problems such as being unfavorable for wide-scale popularization and application, low content of slow-release effective nitrogen, and affecting the slow-release performance of products, etc. Achieve the effect of being conducive to large-scale promotion and application, round product particles, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

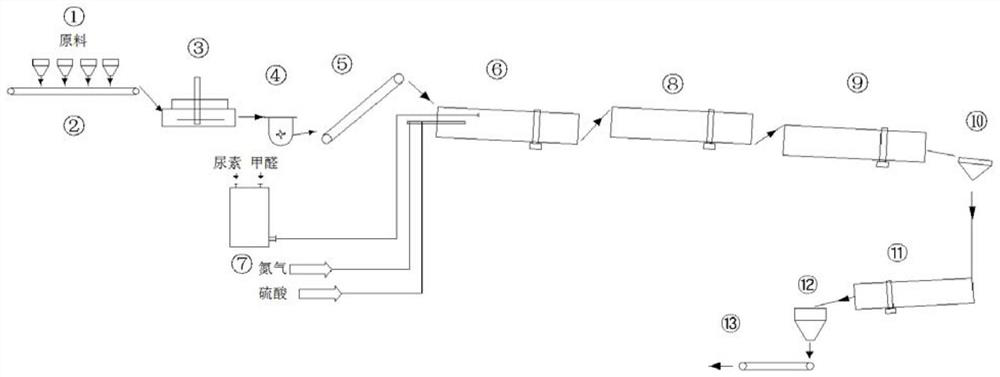

Method used

Image

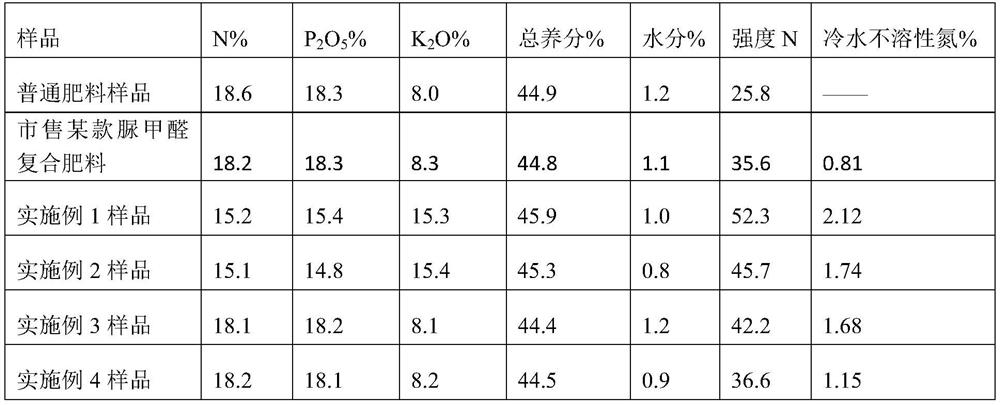

Examples

Embodiment 1

[0040] Embodiment 1: The low-temperature concentrated solution method of the present embodiment directly granulates the method for producing urea-formaldehyde slow-release compound fertilizer as follows:

[0041] (1) Put 560 kilograms of urea and 440 kilograms of 36% formaldehyde solution into a reactor at 30° C. and stir at a stirring speed of 60 r / min to fully dissolve urea to form a mixed solution of urea and formaldehyde.

[0042](2) Use about 15 liters of 20% KOH solution, drop it into the urea-formaldehyde mixed solution, adjust the pH value of the solution to 11, and continue stirring the mixed solution for 2 hours, so that urea and formaldehyde undergo addition reaction to form urea-formaldehyde Addition solution.

[0043] (3) the urea-formaldehyde addition solution is added in the granulation drum according to the flow rate of 1.5 tons / hour, and the amount of other compound fertilizer raw materials in the granulation drum is 10 tons / hour, while spraying 30% sulfuric a...

Embodiment 2

[0045] Embodiment 2: The low-temperature concentrated solution method of the present embodiment directly granulates the method for producing urea-formaldehyde slow-release compound fertilizer as follows:

[0046] (1) Put 500 kilograms of urea and 500 kilograms of 36% formaldehyde solution into a reactor at 40° C. and stir at a stirring speed of 60 r / min to fully dissolve urea to form a mixed solution of urea and formaldehyde.

[0047] (2) Use about 12 liters of 20% NaOH solution, drop it into the urea-formaldehyde mixed solution, adjust the pH value of the solution to 10, and continue stirring the mixed solution for 1.5 hours, so that urea and formaldehyde undergo addition reaction to form urea-formaldehyde Addition solution.

[0048] (3) formaldehyde addition solution is added in the granulation drum according to the flow rate of 1.2 tons / hour, and other compound fertilizer raw materials are 10 tons / hour in the granulation drum, and contain the sulfuric acid solution that spr...

Embodiment 3

[0050] Embodiment 3: The low-temperature concentrated solution method of the present embodiment directly granulates the method for producing urea-formaldehyde slow-release compound fertilizer as follows:

[0051] (1) 580 kg of urea and 420 kg of 36% formaldehyde solution are dropped into a reactor at 50° C. and stirred at a stirring speed of 60 r / min to fully dissolve urea to form a mixed solution of urea and formaldehyde.

[0052] (2) Use about 10 liters of 20% NaOH solution, drop it into the urea-formaldehyde mixed solution, adjust the pH value of the solution to 9, and continue to stir the mixed solution for 1 hour, so that urea and formaldehyde undergo addition reaction to form urea-formaldehyde Addition solution.

[0053] (3) formaldehyde addition solution is added in the granulation drum according to the flow rate of 1.2 tons / hour, and other compound fertilizer raw materials are 10 tons / hour in the granulation drum, and contain the sulfuric acid solution that sprays 40% ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap